Anhui Aoxuan Heavy Industry Machine Co., Ltd. |

|

Verified Suppliers

|

|

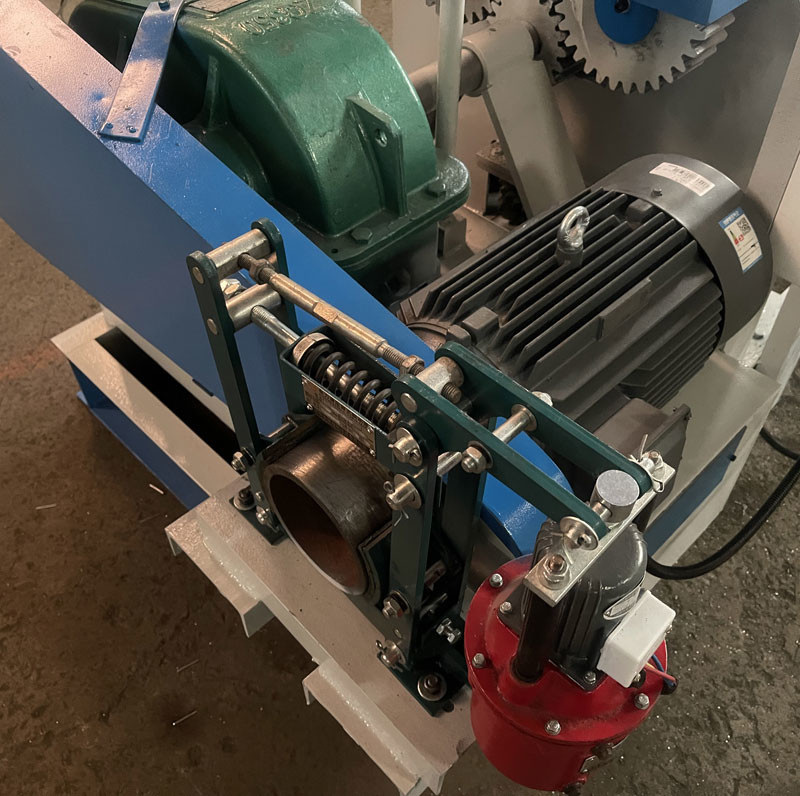

Simple Type Full Automatic Eletric Three Roller Rolling Plate Bending Machine Metal Plate 10*2500mm

Instructions for use

This machine is a W11 three-roller symmetrical upward adjustment

plate rolling machine, which is used for bending metal plates at

normal temperature. Its working principle is formed by rotating and

deforming. It is a necessary equipment for boiler, shipbuilding,

petrochemical, cement, motor and other machine manufacturing

industries.

1. The company has developed and improved the three-roller tail-end

assembly mold, which can be bent such as: steel pipe, channel

steel, angle steel, etc., so that one machine can be used for

multiple purposes (please specify when ordering).

2. This machine has compact structure, convenient operation and

good performance. It is the most widely used plate rolling

equipment in our country at present.

Technical parameter:

| Model type | Max thickness (mm) | Max length (mm) | Upper roller diameter (mm) | Lower roller diameter (mm) | Rollers center distance (mm) | Main motor (kw) | Hydraulic motor power (KW) |

| W11S-12*2000 | 12 | 2000 | 255 | 150 | 245 | 7.5 | 4 |

| W11S-12*2500 | 12 | 2500 | 300 | 165 | 270 | 11 | 5.5 |

| W11S-12*3200 | 12 | 3200 | 320 | 180 | 300 | 15 | 5.5 |

| W11S-16*2000 | 16 | 2000 | 300 | 165 | 270 | 11 | 5.5 |

| W11S-16*2500 | 16 | 2500 | 320 | 180 | 300 | 15 | 5.5 |

| W11S-16*3200 | 16 | 3200 | 380 | 200 | 330 | 22 | 7.5 |

| W11S-20*2000 | 20 | 2000 | 320 | 180 | 300 | 15 | 5.5 |

| W11S-20*2500 | 20 | 2500 | 380 | 220 | 360 | 22 | 7.5 |

| W11S-25*2000 | 25 | 2000 | 380 | 220 | 360 | 22 | 7.5 |

| W11S-25*2500 | 25 | 2500 | 410 | 235 | 380 | 30 | 11 |

| W11S-30*2000 | 30 | 2000 | 410 | 235 | 380 | 30 | 11 |

| W11S-30*2500 | 30 | 2500 | 460 | 260 | 420 | 37 | 15 |

| W11S-30*3000 | 30 | 3000 | 480 | 260 | 420 | 37 | 15 |

| W11S-30*3200 | 30 | 3200 | 510 | 275 | 460 | 45 | 15 |

| W11S-30*4000 | 30 | 4000 | 590 | 290 | 500 | 45 | 22 |

| W11S-40*2000 | 40 | 2000 | 480 | 260 | 420 | 37 | 32 |

| W11S-40*2500 | 40 | 2500 | 520 | 290 | 500 | 55 | 22 |

| W11S-40*3000 | 40 | 3000 | 560 | 290 | 500 | 55 | 22 |

| W11S-40*4000 | 40 | 4000 | 610 | 360 | 650 | 75 | 30 |

| W11S-50*3200 | 50 | 3200 | 610 | 360 | 700 | 75 | 30 |

Instructions for use

1. The feeding of the metal plate and the rotation of the upper

roller make the friction between the metal and the roller drive,

and through the arc formed by the three tangent points where the

three rollers contact the metal plate, the flat plate becomes arc

or cylindrical, parallel Adjust the lifting degree of the upper

roller to achieve the required radius of curvature of the arc.

2. During operation, first confirm that the three rollers are in a

parallel state, then keep a certain distance between the upper

roller and the lower roller (slightly greater than the plate

thickness), and feed the metal plate between the upper and lower

rollers so that the front end of the metal plate reaches the second

For the lower roller, press the down button of the auxiliary motor

to lower the upper roller and press it on the metal plate to

generate pressure on the metal plate. At this time, press the

transfer button of the main motor (the rotation direction is

consistent with the metal plate feeding direction) to make the

lower roller The roller rotates, and the metal plate is fed at this

time, and then the upper roller is slowly lowered, and this is

repeated several times to make the metal plate bend to the desired

shape and size.

3. When unloading, raise the upper roller to the yellow square to

make the end of the upper roller tilt up (pull out the end pin

first and then rise), and then turn over the slider. The rolled

metal cylinder can be released from one end of the upper roller.

Packing Detail:

☂ Each Press Brake with plastic film package first, then placed in

a wooden case, wooden case with a foam filling.

✈ We loaded the truck with heavy trucks for loading the cargo to

the harbor terminal.At the dock we pack the goods in containers and

ship them abroad.

Delivery Detail :

☀ Shipped in 15 days after payment.

FAQ:

1. Are you the manufacture?Can we visit your factory?

We are manufacturer and we are located in Anhui,China.And we have

our own design team for products design.

And welcome you visit our factory and check our machine qualtiy on

spot,any question will be solved on spot at first time.

2.What's your main product and what is your main foreign market?

Our main products are press brake,shears machine,press,cutting

machine,locking machine ,auto duct line and related products.

Our main foreign market are Asia, North America, Europe, Africa.

3. what are the advantages of your machines?And how can i believe

the quality of your product?

The main configuration is to import quality products, and

Professional product quality inspection team ensure machine in

top-quality, precision and life.

For example,Germany Bosch-Rexroth Valve group,Germany Siemens Main

Motor,Schneider Electrics system and so on.

Once tested as qualified .our machine would be sent out.So The quality of our product is stable and reliable.

4. And are you able to update the production process Information in

time after placing our order?

After confirming your order ,we would keep you updated of

production details of emails and photos.

5. Can we be your agent?

Yes,we are looking for Global agent we will help agent improve the

market ,and supply all the service like machine technical problem

or other after-sales problem, meanwhile ,you can get big discount

and commission.

6. Payment terms?

T/T, L/C, Western Union, Paypal, Alibaba Secure Payment ect.

7,Are you provide product metal parts and provide us technical

guidance?

Wearing parts,Disassembly tool(free) are what we could provide.And

we can give you technical guidance.Our technical staff can go

abroad to provide you with technical guidance.

8. How long is your warranty?

13 months free warranty, life-long maintenance.

9.Do you accept customer Logo and customized ?

we accept kinds of customized ,including logo and machine .

If you are interested, please contact me ^-^