Aolittel Technology Co.,Ltd |

|

Flame-proof Non-Inductive KNP 0.25-10W Fusible Wire Wound Resistor

0.1-1000 Ohm ±5% With Smaller Size Available

External dimensions (Unit:mm)

P type

The 5th color band; KNP type in ‘Black’, NKNP type in ‘Green’

| Type | Dimensions | |||||

Normal Size | Small Size | I±2.0 | L±1.0 | ψD | ψd±0.05 | H±2.0 |

KNP1/2W, NKNP1/2W | KNP1WS, NKNP1WS | 60 | 9.0 | 3.2±0.5 | 0.50 | 28 |

KNP1W, NKNP1W | KNP2WS,NKNP2WS | 60 | 11.5 | 4.5±1.0 | 0.68 | 25 |

| 73 | 11.5 | 4.5±1.0 | 0.68 | 31 | ||

KNP2W, NKNP2W | KNP3WS,NKNP3WS | 60 | 15.5 | 5.0±1.0 | 0.68 | 23 |

| 81 | 15.5 | 5.0±1.0 | 0.68 | 33 | ||

KNP3W, NKNP3W | KNP5WS, NKNP5WS | 94 | 17.5 | 6.0±1.0 | 0.68 | 38 |

| KNP5W,NKNP5W | 94 | 24.5 | 8.0±1.0 | 0.68 | 35 | |

Axial Lead Taping

Txx Type

| Type | Taping | Dimensions | ||||||||||

Normal Size | Small Size | L | W | P | L1-L2 Max. | T | Z Max. | R Max. | t Max. | e Max. | S Max. | |

| KNP 1/2W | KNP 1WS | T52 | 9.0±1.0 | 52±1.0 | 5±0.5 | 1.0 | 6±0.5 | 1.2 | 0 | 3.0 | 0.6 | 0.5 |

| KNP 1W | KNP 2WS | T52 | 11.5±1.0 | 52±1.0 | 5±0.5 | 1.0 | 6±0.5 | 1.2 | 0 | 3.0 | 0.6 | 0.5 |

| T66 | 11.5±1.0 | 66±1.0 | 5±0.5 | 1.0 | 6±0.5 | 1.2 | 0 | 3.0 | 0.6 | 0.5 | ||

| KNP2W | KNP 3WS | T52 | 15.5±1.0 | 52±1.0 | 10±0.5 | 1.0 | 6±0.5 | 1.2 | 0 | 3.0 | 0.6 | 0.5 |

| T73 | 15.5±1.0 | 73±1.0 | 10±0.5 | 1.0 | 6±0.5 | 1.2 | 0 | 3.0 | 0.6 | 0.5 | ||

| KNP3W | KNP5WS | T84 | 17.5±1.5 | 84±1.0 | 10±0.5 | 1.0 | 6±0.5 | 1.2 | 0 | 3.0 | 0.6 | 0.5 |

| KNP5W | T84 | 24.5±1.0 | 84±1.0 | 10±0.5 | 1.0 | 6±0.5 | 1.2 | 0 | 3.0 | 0.6 | 0.5 | |

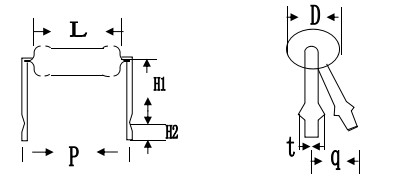

MB Type &M Type&MK Type

MB

Watts | Dimensions (mm) | ||||||

| D | L | P±1.0 | H1±1.0 | H2±0.5 | t±0.15 | qMax | |

| 1/2w,1ws | 3.2±0.5 | 9.0±1.0 | 12.5/15 | 10.5 | 4.5 | 1.2 | 3 |

| 1w,2ws | 4.5±1.0 | 11.5±1.0 | 15 | 10.5 | 4.5 | 1.25 | 3 |

| 2w,3ws | 5.0±1.0 | 15.5±1.0 | 20 | 10.5 | 4.5 | 1.25 | 3 |

| 3W5WS | 6.0±1.0 | 17.5±1.0 | 25 | 10.5 | 4.5 | 1.25 | 3 |

| 5W | 8.0±1.0 | 24.5±1.0 | 30 | 10.5 | 4.5 | 1.25 | 3 |

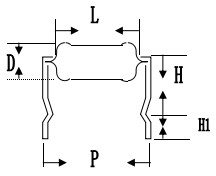

M

Watts | Dimensions (mm) | |||

| ΦD | L | P±1.0 | H±1.0 | |

| 1/2w,1ws | 3.5±0.5 | 9.0±1.0 | 12.5/15 | 10 |

| 1w,2ws | 4.5±1.0 | 11.5±1.0 | 15 | 10 |

| 2w,3ws | 5.0±1.0 | 15.5±1.0 | 20 | 10 |

| 3w | 6.0±1.0 | 17.5±1.0 | 25 | 10 |

| 5w | 8.0±1.0 | 24.5±1.0 | 30 | 10 |

MK

Watts | Dimensions (mm) | ||||

| D | L | P±1.0 | H±1.0 | H1±1.0 | |

| 1/2w,1ws | 3.2±0.5 | 9.0±1.0 | 12.5 | 10 | 4.5 |

| 1w,2ws | 4.5±1.0 | 11.5±1.0 | 15 | 10 | 4.5 |

| 2w,3ws | 5.0±1.0 | 15.5±1.0 | 20 | 10 | 4.5 |

| 3W5WS | 6.0±1.0 | 17.5±1.0 | 25 | 10 | 4.5 |

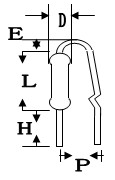

F Type &FK2Type&FKK Type

F

Watts | Dimensions (mm) | ||||

| ΦD | L | P±2.0 | E Max | H±1.0 | |

| 1/2w,1ws | 3.2±0.5 | 9.0±1.0 | 6 | 3.5 | 5-8 |

| 1w,2ws | 4.5±1.0 | 11.5±1.0 | 8 | 3.5 | 5-8 |

| 2w,3ws | 5.0±1.0 | 15.5±1.0 | 8 | 3.5 | 5-8 |

| 3w | 6.0±1.0 | 17.5±1.0 | 8 | 3.5 | 5-8 |

FK2

Watts | Dimensions (mm) | ||||

| ΦD | L | P±2.0 | E Max | H±1.0 | |

| 1/2w,1ws | 3.2±0.5 | 9.0±1.0 | 6 | 3.5 | 5-8 |

| 1w,2ws | 4.5±1.0 | 11.5±1.0 | 8 | 3.5 | 5-8 |

| 2w,3ws | 5.0±1.0 | 15.5±1.0 | 8 | 3.5 | 5-8 |

| 3w | 6.0±1.0 | 17.5±1.0 | 8 | 3.5 | 5-8 |

FKK

Watts | Dimensions(mm) | |||||

| ΦD | L | P±1.0 | E Max | H1±1.0 | H2±1.0 | |

| 1/2w,1ws | 3.2±0.5 | 9.0±1.0 | 5-7 | 3.5 | 8 | 4.5 |

| 1w,2ws | 4.5±1.0 | 11.5±1.0 | 5-9 | 3.5 | 8 | 4.5 |

| 2w,3ws | 5.0±1.0 | 15.5±1.0 | 5-9 | 3.5 | 8 | 4.5 |

| 3w | 6.0±1.0 | 17.5±1.0 | 5-10 | 3.5 | 8 | 4.5 |

Tape in box packing (Ammo packing) Packing box size and quantity

| Type | Form | Quantity | Dimensions (mm) | |||

Normal Size | Small Size | L | W | H | ||

KNP1/2W, NKNP1/2W | KNP1WS, NKNP1WS | T52 | 2000 PCS | 260 | 80 | 85 |

KNP1W, NKNP1W | KNP2WS, NKNP2WS | T52 | 1000 PCS | 260 | 80 | 85 |

| T67 | 1000 PCS | 260 | 85 | 92 | ||

KNP2W, NKNP2W | KNP3WS, NKNP3WS | T52 | 1000 PCS | 260 | 80 | 100 |

| T73 | 1000 PCS | 260 | 95 | 92 | ||

KNP3W, NKNP3W | KNP5WS, NKNP5WS | T84 | 500PCS | 260 | 110 | 75 |

| KNP5W,NKNP5WS | T84 | 250PCS | 260 | 110 | 75 | |

Bulk

| Type | Form | Quantity | Dimensions (mm) | |||

Normal Size | Small Size | L | W | H | ||

KNP1/2W, NKNP1/2W | KNP1WS, NKNP1WS | P | 5000 PCS | 240 | 140 | 76 |

| Moulding | 5000 PCS | 240 | 140 | 76 | ||

KNP1W, NKNP1W | KNP2WS, NKNP2WS | P | 2000 PCS | 240 | 140 | 76 |

| Moulding | 2000 PCS | 240 | 140 | 76 | ||

KNP2W, NKNP2W | KNP3WS, NKNP3WS | P | 2000 PCS | 240 | 140 | 76 |

| Moulding | 2000 PCS | 240 | 140 | 76 | ||

| KNP3W,NKNP3W | KNP5WS, NKNP5WS | P | 100PCS | 240 | 140 | 76 |

| Moulding | 250PCS | 240 | 140 | 76 | ||

| KNP5W,NKNP5WS | P | 50PCS | 240 | 140 | 76 | |

| Moulding | 50PCS | 240 | 140 | 76 | ||

Rated power

Rated power is maximum power which can be continuously loaded at specified ambient temperature

70℃,as Table-1;however when the ambient temperature exceeds 70℃

Type

| Rated power

| Dielectric withstanding voltage | KNP Resistance Range(Ω) | NKNP Resistance Range(Ω) | |

| Normal size | KNP1/2W, NKNP1/2W | 0.5W | 300V | 0.05Ω~1KΩ | 0.1Ω~680Ω |

KNP1W, NKNP1W | 1W | 350V | |||

KNP2W, NKNP2W | 2W | 350V | |||

KNP3W, NKNP3W | 3W | 400V | |||

KNP5W, NKNP5W | 5W | 400V | |||

| Small size | KNP1WS, NKNP1WS | 1W | 300V | 0.05Ω~1KΩ | 0.1Ω~680Ω |

KNP2WS, NKNP2WS | 2W | 350V | |||

KNP3WS, NKNP3WS | 3W | 350V | |||

KNP5WS, NKNP5WS | 5W | 400V | |||

Color Code

| Color |

1st figure | 2nd figure | Multiplier | Tolerance | Distinguish | |

| Black | 0 | 0 | 100 |

KNP type in ‘Black’, NKNP type in ‘Green’. | ||

| Brown | 1 | 1 | 101 | ±1%(F) | ||

| Red | 2 | 2 | 102 | ±2%(G) | ||

| Orange | 3 | 3 | 103 | |||

| Yellow | 4 | 4 | 104 | |||

| Green | 5 | 5 | 105 | |||

| Blue | 6 | 6 | 106 | |||

| Violet | 7 | 7 | 107 | |||

| Gray | 8 | 8 | ||||

| White | 9 | 9 | ||||

| Gold | 10-1 | ±5%(J) | ||||

| Silver | 10-2 | ±10%(K) | ||||

| Plain | ||||||

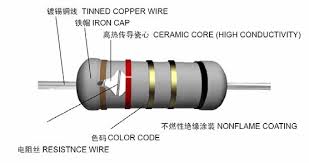

Construction

NO | Item | Material |

| 1 | Ceramic core | High alumina ceramic is used. |

| 2 | Resistor element | The resistor element shall consist of Resistance wire(Exemple:CN49W Φ1.0mm) . |

| 3 | Terminal | Tinned iron cap. |

| 4 | Connection | The lead wire,which is plated with solder,shall be mounted to the caps by welding process. |

| 5 | Lead wire | Soldered or tinned annealed wire. |

| 6 | Finishing painting | Silicon resin is used. Accord with UL-94V-0 Nonflammable specification. |

| 7 | Indication | Color code. |

Characteristics

Item | Performance | Test methods(Conform to JIS C 5202) |

Temperature | ±350PPM/℃ | Comply with 5.2 R1:Resistance value at room temp.plus 100℃(T1) |

| Within ±(2%+0.05Ω). No evidence of mechanical damage. | Comply with 5.5 But not to exceed maximum overload voltage. |

Item | Performance | Test methods(Conform to JIS C 5202) | |||||||||

Insulation | 104MΩ or more. | Comply with 5.6 Resistor shall be tested at DC 500V for 60 seconds. | |||||||||

Dielectric | No evidence of flashover mechanical damage,arcing or insulation breakdown. | Comply with 5.7 Resistor shall be tested at AC potential respectively for 60 seconds.(See table-1) | |||||||||

Pulse overload | Within ±(2%+0.05Ω) | Comply with 5.8 Rated voltage X 4 times, 10000 cyc.(1s ON, 25s OFF) But not to exceed maximum pulse voltage.(See table-1) | |||||||||

Terminal strength | No evidence of mechanical damage. | Comply with 6.1

Torsion strength:To bend the lead wire at the point of about 6mm~6.5mm from resistor body. about 0.75mm curvature radii to 90°then catch the wire at 1.2±0.4mm apart from the bend point end and turn it ( clockwise ) by 360 degrees perpendicular to the resistor axis at speed of same 5 seconds per turn, and do the same counterclockwise again which constitute a whole turn. Repeat the turn for 2 times without causing any break and looseness. |

Item | Performance | Test methods(Conform to JIS C 5202) |

Resistance to soldering heat | Within ±(1%+0.05Ω) No evidence of mechanical damage. | Comply with 6.4 350±10℃, 3±1s After test leave for 0.5h. |

Solderability | Covered with new solder by 95% at least. | Comply with 6.5 Test temperature of solder:255±5℃ Dipping time in solder:3±1.0 s |

Resistance to solvent |

No deterioration of protective coating and markings. | Comply with 6.9 Specimens shall be immersed in a bath of isoproalcohol completely for 3 minutes with ultrasonic. |

Temperature cycle | Within ±(1%+0.05Ω) No evidence of mechanical damage. | Comply with 7.4 |

Load life in humidity | Within ±(5%+0.05Ω) | Comply with 7.9 |

Load life | Within ±(5%+0.05Ω) | Comply with 7.10 |