Aolittel Technology Co.,Ltd |

|

MF52 Black Epoxy Resin Encapsulation Thermal Resistor NTC Thermistor 3KOhm 3950 For Miniature Temperature Sensor

FEATURES

• Long and flexible leads for special mounting or assembly requirements

• AEC-Q200 qualified

• Uni curve sensor

• Short response time

• High temperature accuracy

• Excellent long-term stability

• Epoxy encapsulation

______________________________________________________________________________ Download________

Download________

APPLICATIONS

Temperature measurement, sensing and control in automotive, industrial and consumer electronic equipments.

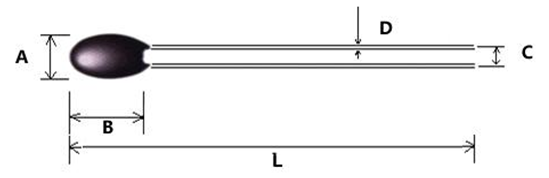

Dimension (mm)

A | B | C | D | L |

Max 30 | Max 4.5 | Max 2.5 | 0.33±0.05 | 33±3 |

Material

NO | Material Name | Item/PN |

E. | Element | R25=3KΩ±1% B25/50=3950±1% |

B | Coating | Epoxy resin |

D. | Lead Wire | 0.33mm CP Wire |

Performances

NO | Item | Sign | Test Conditions | Min. | Normal value | Max. | Unit |

4-1. | Resistance at 25℃ | R25 | Ta=25±0.05℃ PT≦0.1mw | 2.97 | 3.0 | 3.03 | kΩ |

4-2. | B Value | B25/50 |

| 3910.5 | 3950 | 3989.5 | k |

4-3. | Dissipation factor | σ | In still air | ≥0.9 | mw/℃ | ||

4-4. | Time constant | τ | In still air | ≦8 | sec | ||

4-5. | Operating temp.range | / | / | -40 | / | +125 | ℃ |

4-6 | Insulation resistance | / | 100V DC 1min | ≥100 | MΩ | ||

4-7. | Maximum rated power | Pmax | / | ≤25 | mW | ||

Reliability Test

NO | Item | Technical requirements | Test conditions and method |

5-1. | Weldability | R25 △R/R≤±2% | Temperature: 260℃±5℃, Time:2-3Sec |

5-2. | Resistance To Soldering Heat | R25 △R/R≤±2% | Tin stove temperature: ≤260±5℃, Immersion depth is ≤6mm distance far away with body, Time:5±1Sec |

5-3 | Steady State Temperatur | R25 △R/R≤±2% | Temperature:40±2℃; Humidity:93±2%, Time:300H |

5-4 | Temp. cycle test | R25 △R/R≤±2% |

|

5-5. | High temperature storage | R25 △R/R≤±2% | Temperature:120±5℃; Time:300H |

5-6 | Low temperature storage | R25 △R/R≤±2% | Temperature:-20℃; Time:300H |

5-7 | Drop test | No visible damage | Free fall into concrete floor from height 1M ,5 cycle. |

5-8 | Bending test | Bend 90°binding site wire and epoxy resin.Back and forth 3 times | |

5-9 | Tensile tests | Fixed resistors at both ends ,Pull: 10±1N, Time: 5±1 Sec |

R-T Table

| R-T CONVERSION TABLE | |||||||

| R25=3±1% B25/50=3950±1% | |||||||

| T(℃) | Rmin (KΩ) | Rcen (KΩ) | Rmax (KΩ) | T(℃) | Rmin (KΩ) | Rcen (KΩ) | Rmax (KΩ) |

| -40 | 87.2093 | 91.1817 | 95.2604 | -5 | 12.3253 | 12.6319 | 12.9411 |

| -39 | 82.1071 | 85.7943 | 89.578 | -4 | 11.7125 | 11.9976 | 12.285 |

| -38 | 77.3288 | 80.752 | 84.2628 | -3 | 11.1331 | 11.3982 | 11.6654 |

| -37 | 72.8525 | 76.0313 | 79.2895 | -2 | 10.5852 | 10.8317 | 11.08 |

| -36 | 68.6572 | 71.6095 | 74.6339 | -1 | 10.0669 | 10.296 | 10.5267 |

| -35 | 64.7238 | 67.4663 | 70.2742 | 0 | 9.5765 | 9.7895 | 10.0039 |

| -34 | 61.0349 | 63.583 | 66.1904 | 1 | 9.1063 | 9.3041 | 9.503 |

| -33 | 57.574 | 59.9419 | 62.3636 | 2 | 8.6618 | 8.8454 | 9.03 |

| -32 | 54.3258 | 56.5266 | 58.7761 | 3 | 8.2417 | 8.4121 | 8.5834 |

| -31 | 51.2763 | 53.3221 | 55.4121 | 4 | 7.8444 | 8.0026 | 8.1615 |

| -30 | 48.4125 | 50.3145 | 52.2565 | 5 | 7.4685 | 7.6153 | 7.7627 |

| -29 | 45.6655 | 47.4313 | 49.2333 | 6 | 7.1128 | 7.249 | 7.3857 |

| -28 | 43.0892 | 44.7289 | 46.4012 | 7 | 6.7761 | 6.9024 | 7.0292 |

| -27 | 40.6723 | 42.1951 | 43.7474 | 8 | 6.4573 | 6.5744 | 6.6919 |

| -26 | 38.4038 | 39.8184 | 41.2596 | 9 | 6.155 | 6.2636 | 6.3725 |

| -25 | 36.274 | 37.5882 | 38.9265 | 10 | 5.869 | 5.9696 | 6.0705 |

| -24 | 34.2734 | 35.4946 | 36.7375 | 11 | 5.5976 | 5.6908 | 5.7843 |

| -23 | 32.3939 | 33.5288 | 34.6833 | 12 | 5.3405 | 5.4268 | 5.5133 |

| -22 | 30.6271 | 31.682 | 32.7545 | 13 | 5.0966 | 5.1765 | 5.2566 |

| -21 | 28.9659 | 29.9465 | 30.943 | 14 | 4.8651 | 4.9391 | 5.0132 |

| -20 | 27.4035 | 28.3152 | 29.2412 | 15 | 4.6455 | 4.7139 | 4.7824 |

| -19 | 25.9275 | 26.7749 | 27.6352 | 16 | 4.4369 | 4.5001 | 4.5634 |

| -18 | 24.5387 | 25.3265 | 26.1258 | 17 | 4.239 | 4.2974 | 4.3558 |

| -17 | 23.2316 | 23.9641 | 24.7069 | 18 | 4.051 | 4.1049 | 4.1588 |

| -16 | 22.0011 | 22.6822 | 23.3725 | 19 | 3.8721 | 3.9218 | 3.9715 |

| -15 | 20.8422 | 21.4755 | 22.1171 | 20 | 3.7025 | 3.7483 | 3.7941 |

| -14 | 19.7502 | 20.3392 | 20.9356 | 21 | 3.5409 | 3.5831 | 3.6253 |

| -13 | 18.721 | 19.2687 | 19.8231 | 22 | 3.3874 | 3.4262 | 3.465 |

| -12 | 17.7507 | 18.2601 | 18.7755 | 23 | 3.2413 | 3.277 | 3.3127 |

| -11 | 16.8357 | 17.3095 | 17.7886 | 24 | 3.1024 | 3.1351 | 3.1678 |

| -10 | 15.9725 | 16.4132 | 16.8587 | 25 | 2.97 | 3 | 3.03 |

| -9 | 15.1569 | 15.5668 | 15.9809 | 26 | 2.8414 | 2.8714 | 2.9014 |

| -8 | 14.3871 | 14.7683 | 15.1533 | 27 | 2.7179 | 2.7478 | 2.7777 |

| -7 | 13.6605 | 14.015 | 14.3729 | 28 | 2.6003 | 2.6301 | 2.6599 |

| -6 | 12.9739 | 13.3036 | 13.6363 | 29 | 2.4886 | 2.5182 | 2.5478 |

| R-T CONVERSION TABLE | |||||||

| R25=3±1% B25/50=3950±1% | |||||||

| T(℃) | Rmin (KΩ) | Rcen (KΩ) | Rmax (KΩ) | T(℃) | Rmin (KΩ) | Rcen (KΩ) | Rmax (KΩ) |

| 30 | 2.3825 | 2.4119 | 2.4413 | 65 | 0.6084 | 0.6244 | 0.6405 |

| 31 | 2.2815 | 2.3106 | 2.3397 | 66 | 0.5876 | 0.6032 | 0.619 |

| 32 | 2.1853 | 2.2142 | 2.2431 | 67 | 0.5675 | 0.5828 | 0.5983 |

| 33 | 2.0938 | 2.1224 | 2.151 | 68 | 0.5481 | 0.5631 | 0.5782 |

| 34 | 2.0068 | 2.035 | 2.0633 | 69 | 0.5296 | 0.5443 | 0.5591 |

| 35 | 1.9238 | 1.9517 | 1.9796 | 70 | 0.5119 | 0.5262 | 0.5407 |

| 36 | 1.845 | 1.8725 | 1.9001 | 71 | 0.4947 | 0.5087 | 0.5229 |

| 37 | 1.7696 | 1.7968 | 1.824 | 72 | 0.4783 | 0.492 | 0.5059 |

| 38 | 1.6978 | 1.7246 | 1.7514 | 73 | 0.4626 | 0.476 | 0.4896 |

| 39 | 1.6295 | 1.6559 | 1.6823 | 74 | 0.4472 | 0.4604 | 0.4737 |

| 40 | 1.5642 | 1.5902 | 1.6162 | 75 | 0.4327 | 0.4456 | 0.4586 |

| 41 | 1.502 | 1.5276 | 1.5532 | 76 | 0.4186 | 0.4312 | 0.444 |

| 42 | 1.4427 | 1.4678 | 1.493 | 77 | 0.4051 | 0.4174 | 0.4299 |

| 43 | 1.386 | 1.4107 | 1.4355 | 78 | 0.3919 | 0.404 | 0.4162 |

| 44 | 1.3318 | 1.3561 | 1.3805 | 79 | 0.3795 | 0.3913 | 0.4033 |

| 45 | 1.2803 | 1.3042 | 1.3282 | 80 | 0.3674 | 0.379 | 0.3907 |

| 46 | 1.2308 | 1.2542 | 1.2777 | 81 | 0.3558 | 0.3671 | 0.3786 |

| 47 | 1.1838 | 1.2068 | 1.2299 | 82 | 0.3445 | 0.3556 | 0.3668 |

| 48 | 1.1386 | 1.1612 | 1.1839 | 83 | 0.3338 | 0.3446 | 0.3556 |

| 49 | 1.0955 | 1.1177 | 1.14 | 84 | 0.3234 | 0.334 | 0.3448 |

| 50 | 1.0544 | 1.0761 | 1.098 | 85 | 0.3133 | 0.3237 | 0.3342 |

| 51 | 1.0148 | 1.0361 | 1.0575 | 86 | 0.3039 | 0.314 | 0.3243 |

| 52 | 0.977 | 0.9979 | 1.0189 | 87 | 0.2945 | 0.3044 | 0.3145 |

| 53 | 0.9408 | 0.9613 | 0.9819 | 88 | 0.2855 | 0.2952 | 0.3051 |

| 54 | 0.9061 | 0.9262 | 0.9464 | 89 | 0.2769 | 0.2864 | 0.2961 |

| 55 | 0.873 | 0.8927 | 0.9125 | 90 | 0.2687 | 0.278 | 0.2875 |

| 56 | 0.8413 | 0.8606 | 0.88 | 91 | 0.2607 | 0.2698 | 0.2791 |

| 57 | 0.8108 | 0.8297 | 0.8487 | 92 | 0.2529 | 0.2618 | 0.2709 |

| 58 | 0.7817 | 0.8002 | 0.8188 | 93 | 0.2453 | 0.254 | 0.2629 |

| 59 | 0.7537 | 0.7718 | 0.7901 | 94 | 0.2381 | 0.2467 | 0.2554 |

| 60 | 0.7269 | 0.7447 | 0.7626 | 95 | 0.2311 | 0.2395 | 0.248 |

| 61 | 0.7012 | 0.7186 | 0.7361 | 96 | 0.2244 | 0.2326 | 0.241 |

| 62 | 0.6765 | 0.6935 | 0.7107 | 97 | 0.2179 | 0.2259 | 0.2341 |

| 63 | 0.6528 | 0.6695 | 0.6863 | 98 | 0.2116 | 0.2195 | 0.2275 |

| 64 | 0.6303 | 0.6466 | 0.6631 | 99 | 0.2057 | 0.2134 | 0.2212 |

| R-T CONVERSION TABLE | |||||||

| R25=3±1% B25/50=3950±1% | |||||||

| T(℃) | Rmin (KΩ) | Rcen (KΩ) | Rmax (KΩ) | T(℃) | Rmin (KΩ) | Rcen (KΩ) | Rmax (KΩ) |

| 100 | 0.1998 | 0.2073 | 0.215 | ||||

| 101 | 0.1942 | 0.2016 | 0.2091 | ||||

| 102 | 0.1886 | 0.1958 | 0.2032 | ||||

| 103 | 0.1833 | 0.1904 | 0.1976 | ||||

| 104 | 0.1781 | 0.185 | 0.1921 | ||||

| 105 | 0.1733 | 0.1801 | 0.187 | ||||

| 106 | 0.1685 | 0.1752 | 0.182 | ||||

| 107 | 0.1639 | 0.1704 | 0.1771 | ||||

| 108 | 0.1593 | 0.1657 | 0.1722 | ||||

| 109 | 0.1549 | 0.1612 | 0.1676 | ||||

| 110 | 0.1507 | 0.1568 | 0.1631 | ||||

| 111 | 0.1465 | 0.1525 | 0.1586 | ||||

| 112 | 0.1426 | 0.1485 | 0.1545 | ||||

| 113 | 0.1387 | 0.1445 | 0.1504 | ||||

| 114 | 0.1351 | 0.1407 | 0.1465 | ||||

| 115 | 0.1314 | 0.1369 | 0.1426 | ||||

| 116 | 0.1279 | 0.1333 | 0.1388 | ||||

| 117 | 0.1246 | 0.1299 | 0.1353 | ||||

| 118 | 0.1212 | 0.1264 | 0.1317 | ||||

| 119 | 0.118 | 0.1231 | 0.1283 | ||||

| 120 | 0.1149 | 0.1199 | 0.125 | ||||

| 121 | 0.1119 | 0.1168 | 0.1218 | ||||

| 122 | 0.1092 | 0.114 | 0.1189 | ||||

| 123 | 0.1064 | 0.1111 | 0.1159 | ||||

| 124 | 0.1037 | 0.1083 | 0.113 | ||||

| 125 | 0.101 | 0.1055 | 0.1101 | ||||