Aolittel Technology Co.,Ltd |

|

Motor Protection Limitor Non-Resettable TF 172C 250V 10A AUPO TCO Thermal Cutoff Fuse BF172 With Metal Casing

Ao littel-Aupo thermal cutoff fuse Introduction

AUPO thermal cutoff fuse was established in 1986 ,which is an advanced high-tech enterprise that specialized in thermal links (thermal protectors) research and development, production and sale. Developed more than 10 series 100 models of thermal links, and our annual productivity achieves 1 billion pieces. The AUPO strictly operates under superior management system and quality assurance system based on ISO9001. Also our products have been recognized and certificated by a number of domestic and foreign safety laboratories including UL, CUL, VDE, TUV, CSA, PSE, KTL-EK, CCC, and so on. Our own laboratory has been certified by UL and VDE as the witness laboratory.

______________________________________________________________________________ Download________

Download________

Product Overview

The thermal cutoff fuse (TCO) are non resetting, thermally

sensitive, single pole, normally closed devices and are

intended to be used in various appliances.A temperature sensitive

thermal cutoff fuse melts and opens electrical contacts when

temperatures exceed the rating of the thermal fuse. Thermal cutoff

fuse are providing protection against potentially hazardous

overheating conditions in billions of products around the world.

Standard product offerings include:

Thermal Cutoff Fuse

* Metallic Case type (Axial, Spring Action, Current : 10A

,15A)

* Low melting alloy type ( Axial, Surface tension type, Current :

2A, 5A)

Note that the TCO shall be connected at the readily detectable

location when abnormal conditions such as thermostat failure, fan

failure, locked rotor, dry operation, etc.,might occurr in the

appliance.

TCO is designed to lessen the heat created from TCO itself, but

there may be a difference between the

ambient temperature and operating temperature of TCO due to wrong

connection method.

In order to minimize the difference between ambient temperature and

operating temperature of TCO, it is recommended that the creation

of heat can be minimized around the TCO connected area under normal

operating condition, but the heat generation can be maximized at

TCO connected area under abnormal condition.

Specification

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ○ Pending;● Approved | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Operation Description

Dimension

unit:mm

Application

PRECAUTION FOR LEAD CONNECTION

* Be careful to be free from damage, burn, nick, crack or

overheating at TCO seal or body.If there are such damage as

above, do not use.

* Experimental assembly trials should be made to check the damage

of lead wire, seal or TCO body.

* When connecting wire to TCO, it is recommended that splice or

terminal shall be used. The material of splice or terminal

should be corrosion resistant.

* When securing the splice or terminal to TCO, be careful not to

damage the TCO body. The material of splice or terminal should

be low heat resistace. Be careful not to cause excessive

overheating due to poor connection method. It should be noted

that the connection wire shall be flexible standard wire. If using

solid wire, use the bending process.

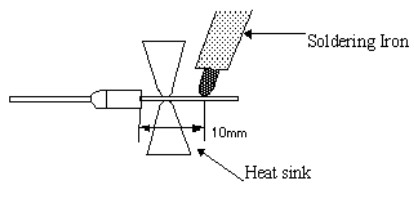

SOLDERING OF LEAD

The following points should be noted if soldering is used to

connect TCO lead.

* Do soldering work on lead as far away from the TCO body if

possible.

* Be careful to minimize the heat transfer to TCO body. When proper

means to prevent the heat transfer is not provided, TCO seal or

body may be damaged and broken-down.

* To shorten the working time, employ pre-soldering process at the

intended soldering area.

* Soldering Method to prevent heat.(use heatsink)

* Mechanical security must not depend on solder alone.

* Electric current must not pass through inner electric contact or

the case of TCO when soldering. The passing of excess current

damages the TCO element or case.

* Tensile strength of lead

Pull force shall not be over 2kg and push force shall not be over

0.5 kg.

* Strength of Case

Applying the excessive force to tie the case body causes

deformation and effects normal operation of TCO.Since this may

cause the fuse to not properly operate, be sure to avoid the

excessive tying force.

* Functioning Temperature Test

Install the TCO in a chamber and gradually increasing temperature

upto 20°C lower than Tf, then if the temperature of the

chamber and the testing products are made equal, the temperature is

increased 1°C per minute, then the fuse will function within

the specified tolerance.

* Temperature Increase Test

When normal operating voltage and current are applied to the TCO in

ambient temperature (20~25) °C the temperature of the TCO will

go up.But the increase of temperature shall not be more than 10°C

* Insulation Resistance

After having operated in temperature test, the insulation

resistance shall be more then 0.2 ohms when tested with 500V

resistance measuring machine.

* Contact Resistance Test

The resistance of the both leads of the TCO should not exceed 1.5

ohms within the 10mm length of the leads.

* Dielectric Voltage Withstand Test

After conducting the Insulation resistance test, the TCO shall be

maintained without breakdown when AC 500V is applied between

the leads of the TCO for 1 Min

.

* Humidity Test

After keeping the TCO in the chamber with humidity 90~95% and specified below condition for 500 hours, the TCO shall pass the Functioning temperature test.

| Tf | Chamber Temperature | Humidity |

| 100 °C less | 40 ± 2 °C | 90~95% |

| 100 °C over | 65 ± 2 °C |

*Aging Test

After keeping the TCO at the temperature 20 ± 3 °C lower then the Tf for 48 hours,the TCO shall pass the Functioning temperature test

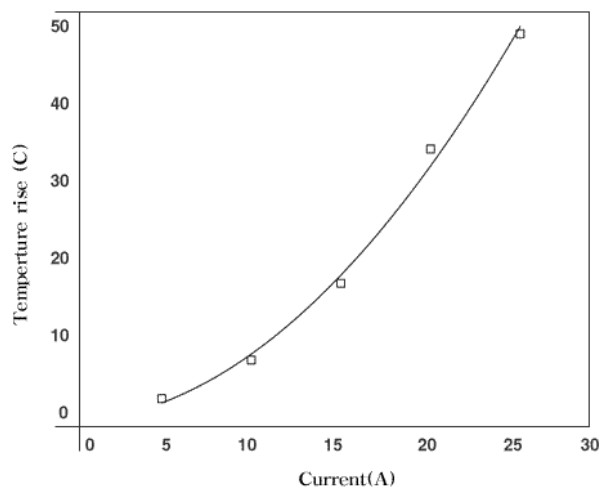

* Temperature Rise Graph

Agency Approvals

| PN | UL/CUL | VDE | CCC | PSE | KTL |

| BF172 | E140847 | 40005418 | 2003010205052188 | JET0749-32001-1012 | SU05017-11004 |

Company Certificates

| Certificate Standard:ISO 9001:2008 | Number:CN99/16675 |

| Issue Date:20-Mar-2017 | Expiry Date:15-Sep-2018 |

| Issued By:SGS | |

| Certificate Standard:ISO 14001 | Number:CN13/30311 |

| Issue Date:29-Feb-2016 | Expiry Date:15-Sep-2018 |

| Issued By:SGS | Scope/Range:Design and manufacture of thermal cutoffs |

| Certificate Standard:OHSAS 18001 | Number:CN16/30181 |

| Issue Date:05-Feb-2016 | Expiry Date:04-Feb-2019 |

| Issued By:SGS | Scope/Range:Design and manufacture of thermal cutoffs |

Factory Photos

FACTORY BUILDING |

OEM product lines |

Equipment room |

Models room |

Developing new products |

Research and development department |

Checkout Room |

Finished product checking |

Quality test equipments |

Services and Support Department |

Machinery/Equipment for R&D

| Molding plastics machine |

Move-printing machine |

| Shredding machine |

| Silk making machine |

| Thermostatic drying cabinet |

| Recording instrument |

| X-ray machine |