Guangdong Yonglong Aluminum Co., Ltd. |

|

In the past, people preferred steel structure to build solar

houses, but gradually found that steel structures have many

disadvantages, such as rust, aging, deformation, air leakage and so

on. With the improvement of the requirements for the manufacturing

process of the solar house, the bridge aluminum with better

performance has replaced the steel structure and become the main

material for the construction of the solar house.

The broken leg aluminum divides the aluminum alloy steel into two

pieces from the middle, separates the indoor and outdoor two layers

of aluminum alloy with a heat bar, and closely connects to form a

new insulated aluminum steel, which solves the disadvantage of

rapid conduction and cooling of aluminum alloy.

The thermal conductivity K value of bridge broken aluminum profile

is lower than 3w/ ㎡ K, which reduces the heat loss by half compared

with ordinary steel, reduces the heating cost by about 30%, and

achieves the insulation effect. In winter, broken bridge aluminum

doors and windows with heat insulation strips can reduce the heat

loss of doors and windows by at least 1/3. In summer, doors and

windows with thermal insulation strips can block the heat generated

outside.

Some businesses believe that mixing low-quality and low-cost PVC or

domestic nylon short heat with high-quality imported nylon 66 short

heat agent will not have much problem even if there is a quality

risk. Sunshine room warns not to use low-quality thermal barrier.

The quality of thermal barrier will seriously affect the

reliability of the contour, and Bridge broken aluminum contour may

appear in the connection of thermal barrier. Therefore, the

material selection and manufacturing process of thermal barrier are

very important.

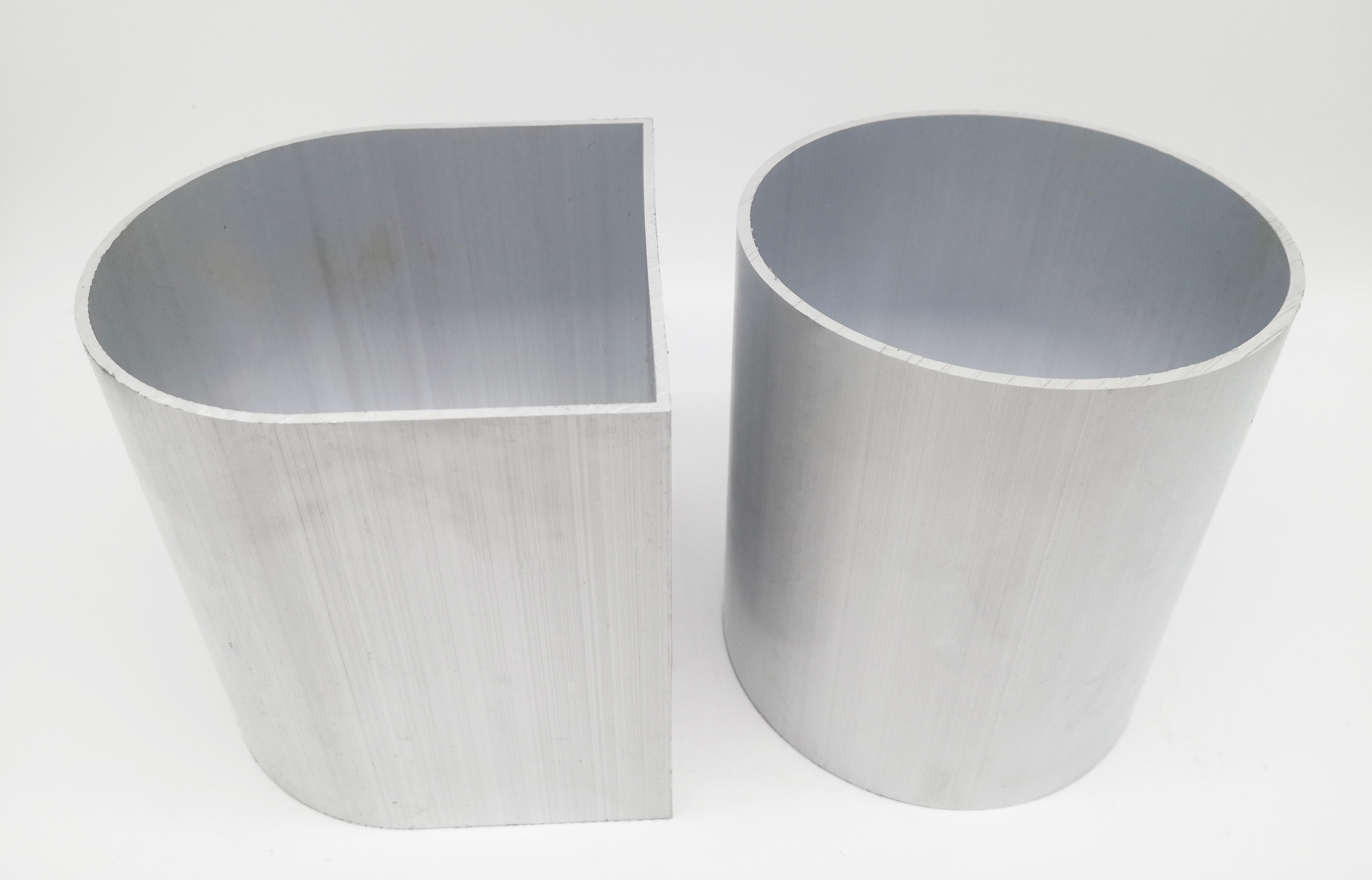

| Description | 6063 T5 High Hardness Aluminum Extrusion Aluminum Sun Room Kits Profiles |

| Material Thickness(t) | 0.8-14 mm |

| Materiral | aluminum alloy 6063,6061 |

| Annealing Treatment | T3-T8 |

| Color | Silver White ,Bronze , Champagne, Black, (RAL series)etc. |

| Surface Treatment | anodized, powder coated, electrophoresis, wood grain, polished and etc |

| Shape | Square, Round, Flat, Oval, and according to customer's drawing. |

| Length | Normal length=6m or in customer's order |

| Usage | Building, Production Line, Decoration, Industrial, Transportation, Door and window, etc. |

| Package | 1. Pearl cotton foam for each profile; 2. Wrap with shrink film exterior; 3. Packed according to customer request. |

| Advantages/Features | Providing colorful products with various mechanical performances to adapt all kinds of architectural styles |

The density of aluminum profiles is only 2.7 g/cm3, which is about a third of the density of steel, copper or brass (7.83 g/cm3, 8.93 g/cm3). In most environmental conditions, including air, water (or brine), petroleum chemistry, and many chemical systems, aluminum shows excellent resistance to corrosion.

Electrical conductivity

The aluminum profile is often chosen because of its excellent conductivity. On the basis of weight, aluminium is nearly twice as conductive as copper.

Thermal conductivity of rate

The thermal conductivity of aluminum alloy volume rate is about 50-60% of copper, the manufacturing heat exchangers, evaporators, heating appliances, cooking utensils, as well as the automobile cylinder head and radiator are favorable.

The ferromagnetic

The aluminum profile is non-ferromagnetic, which is an important feature for the electric and electronic industries. Aluminum profiles are not self-igniting, which is important for applications that involve loading and unloading or touching inflammable and explosive materials.

Can machine processability

The machinability of aluminium profile is excellent. In deformation and aluminum casting aluminum alloy, as well as in the alloy after output with the various states, the change of the machining features is quite big, this will require a special machine tool or technology.

formability

Specific tensile strength, yield strength, malleability, and corresponding processing hardening rate dictate the change in the amount of deformation allowed.

Guangdong Yong long Aluminum Co., Ltd. is located in the No. 10 (Sanjiang market) of Leping Town, Sanshui District, Foshan. The company was founded in 1997. Our factory has introduced advanced production equipment in our factory, including automatic vertical spraying production lines, automatic anodizing and electrophoresis production lines, 5,000MT extruding machine. We can customize different surface treatments for the customers. Our products have been approved and passed with international certificates.

In recent years, there are many types of aluminum curtain tracks in the market, such as rolling, horizontal pulling and rollers type. We supply 10,000 tons ofaluminum curtain track to the market every year. We usually produce the profiles according to the drawings or samples from the customers. We are expecting to invite more curtain track manufacturers to visit our factory and have further discussions about aluminum curtain tracks order, we believe our products quality and price will satisfy you.

1.20 years' experience and advanced equipment

2.Customize: We can manufacture according to your size and shape of such aluminum profile;

3.Strong production capacity - 28 extrusion lines, 50,000TONS/Year

4.One Stop Service Specialized in mould, extrusion, anodizing, powder coating, wood grain and Processing;

5.Shortest Delivery , competitive prices and excellent service

Q – What is the average lead time for pre production samples?

A – Our average lead time is normally 7 days for making new samples and 7 days for testing , totally need about 14days.

Q – What is the average lead time for mass production?

A – Our average lead time is delivery within 20-30 days after receive deposit and and moulds/samples are passed.

Q – What is CAD?

A – CAD stands for “computer assisted design” and it is a 3-D program that is used by our clients to provide our technicians with a three-dimensional example of the custom shape that they want made at GUANGDONG YONGLONG ALUMINUM.

1. Where you intend to use the aluminium profiles?

2. If you have the estrusion drawing, send us and we develop the correspondence mold.

3. Which color you want or tell us the architectural style you like.

4. Purchase quantity. It will convenient us to give you the best price.