KALU INDUSTRY |

|

Verified Suppliers

|

|

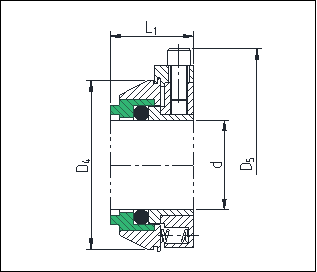

KL-CS component seal replace AES CS mechanical seal balance multiple spring

Replacement of AES Type CS mechanical seal, multiple spring design, balanced seal.

Temperature: -20℃-200℃

Speed: ≤10m/s

Pressure: ≤0.8Mpa

Standard Size: 24-100mm

Rotary face: Carbon/Stainless steel

Static Oring:,EPDM,NBR,AFLAS,KALREZ

Features:

a.External seal with hydraulically balanced seal face

b.Non-metallic wetted parts for use in chemical applications

c.supplied clipped and pre-set to working length

d.Available with collet drive for use with hardened or non-metallic sleeves

e.Springs not in contact with product

Our products are widely used in petroleum, chemistry, refinery, paper making, food,pharmaceutical, textile,power,marine...

We supply Spring pusher seals,Rubber bellow mechanical seals,PTFE bellow mechanical seal,Metal Bellow Seals,Cartridge Seals,Mixer and Agitator seals,Dry Gas Seals.

Besides,spare parts with material silicon carbide, Tungsten carbide, Carbon ,Ceramic,rubber and stainless steel also can be offered.

| Size/Metric | L1 | D4 | D5 | Size/Metric | L1 | D4 | D5 | |

| 20 | 27.9 | 45.3 | 59.8 | 0.625 | 1.098 | 1.622 | 2.192 | |

| 22 | 27.9 | 47.3 | 61.8 | 0.750 | 1.098 | 1.747 | 2.317 | |

| 24 | 27.9 | 49.3 | 63.8 | 0.875 | 1.098 | 1.872 | 2.442 | |

| 25 | 27.9 | 50.3 | 64.8 | 1.000 | 1.098 | 1.997 | 2.567 | |

| 28 | 27.9 | 53.3 | 67.8 | 1.125 | 1.098 | 2.122 | 2.692 | |

| 30 | 27.9 | 55.3 | 69.8 | 1.250 | 1.098 | 2.247 | 2.817 | |

| 32 | 27.9 | 57.3 | 71.8 | 1.375 | 1.098 | 2.372 | 2.942 | |

| 33 | 27.9 | 58.3 | 72.8 | 1.500 | 1.098 | 2.497 | 3.067 | |

| 35 | 27.9 | 60.3 | 74.8 | 1.625 | 1.098 | 2.622 | 3.192 | |

| 38 | 27.9 | 63.3 | 77.8 | 1.750 | 1.098 | 2.747 | 3.317 | |

| 40 | 27.9 | 65.3 | 79.8 | 1.875 | 1.098 | 2.872 | 3.442 | |

| 42 | 27.9 | 67.3 | 81.8 | 2.000 | 1.098 | 2.997 | 3.567 | |

| 43 | 27.9 | 68.3 | 82.8 | 2.125 | 1.098 | 3.122 | 3.692 | |

| 45 | 27.9 | 70.3 | 84.8 | 2.250 | 1.098 | 3.247 | 3.817 | |

| 48 | 27.9 | 73.3 | 87.8 | 2.375 | 1.098 | 3.372 | 3.942 | |

| 50 | 27.9 | 75.3 | 89.8 | 2.500 | 1.098 | 3.497 | 4.067 | |

| 53 | 27.9 | 78.3 | 92.8 | 2.625 | 1.192 | 3.866 | 4.436 | |

| 55 | 27.9 | 80.3 | 94.8 | 2.750 | 1.192 | 3.991 | 4.561 | |

| 60 | 27.9 | 85.3 | 99.7 | 2.875 | 1.192 | 4.116 | 4.686 | |

| 65 | 30.3 | 96.5 | 111.0 | 3.000 | 1.192 | 4.241 | 4.811 | |

| 70 | 30.3 | 101.5 | 116.0 | 3.125 | 1.192 | 4.366 | 4.936 | |

| 75 | 30.3 | 106.5 | 121.0 | 3.250 | 1.192 | 4.491 | 5.061 | |

| 80 | 30.3 | 111.5 | 126.0 | 3.375 | 1.192 | 4.616 | 5.186 | |

| 85 | 30.3 | 116.5 | 131.0 | 3.500 | 1.192 | 4.741 | 5.311 | |

| 90 | 30.3 | 121.5 | 136.0 | 3.625 | 1.192 | 4.866 | 5.436 | |

| 95 | 30.3 | 126.5 | 141.0 | 3.750 | 1.192 | 4.991 | 5.561 | |

| 100 | 30.3 | 131.5 | 146.0 | 3.875 | 1.192 | 5.116 | 5.686 | |

| 4.000 | 1.192 | 5.241 | 5.811 |

Factory tour:

Packing & Shipment:

Delivery:

1. If the products we have in store, we will send it out ASAP after

receiving payment.

2. If the products which were customized, we will complete the

production within a specified period of time, and send it out the

first time.

3. Also we can send by your delivery acount if you want.

4. We have a variety of ways to send goods, usually DHL, Fedex,

TNT, UPS will be normal ways. If you require use of a courier,

please inform us in advance.

Fixing and Applying Directions of Mechanical Seals

1) Select Appropriate mechanical seal to match the materials

according to work conditions and host machine equipment.

2) The radial acting deviation for the shaft(shaft sleeve) of the

installed mechanical seal shall be 0.04mm by maximum

while the axial movement value of the rotor shall be no more than

0.1mm.

3) The seal cover (or shaft cover) of the stationary ring of the

installed mechanical seals,the vertical degree of the seal

face should be 0.04mm by maximum.

4) When installing the mechanical seals,the shaft(shaft

sleeve),seal chamber,seal face as well as the mechanical seal

must be cleaned in order to keep from any medium to sealing part.

5) When conveying medium of over high or low temperature,with

medium which are easy catch fire,easy for explosion.

Related mechanical seal standards must be referred to take

appropriate measures such as quench,rinsing,coolong and

filtrating.

6) Appropricate lubrication must be choosen when mechanical seal is

installed.The installment size of the mechanical

seal must be guaranteed to the installment instruction.

7) Before the machine starts running,the hermetic compartment shall

be full of medium and well lubricated.Dry friction

which may lead to the damage of the air-tightness is strict

forbidden.