Jinan Hydeb Thermal Tech Co., Ltd. |

|

Verified Suppliers

|

|

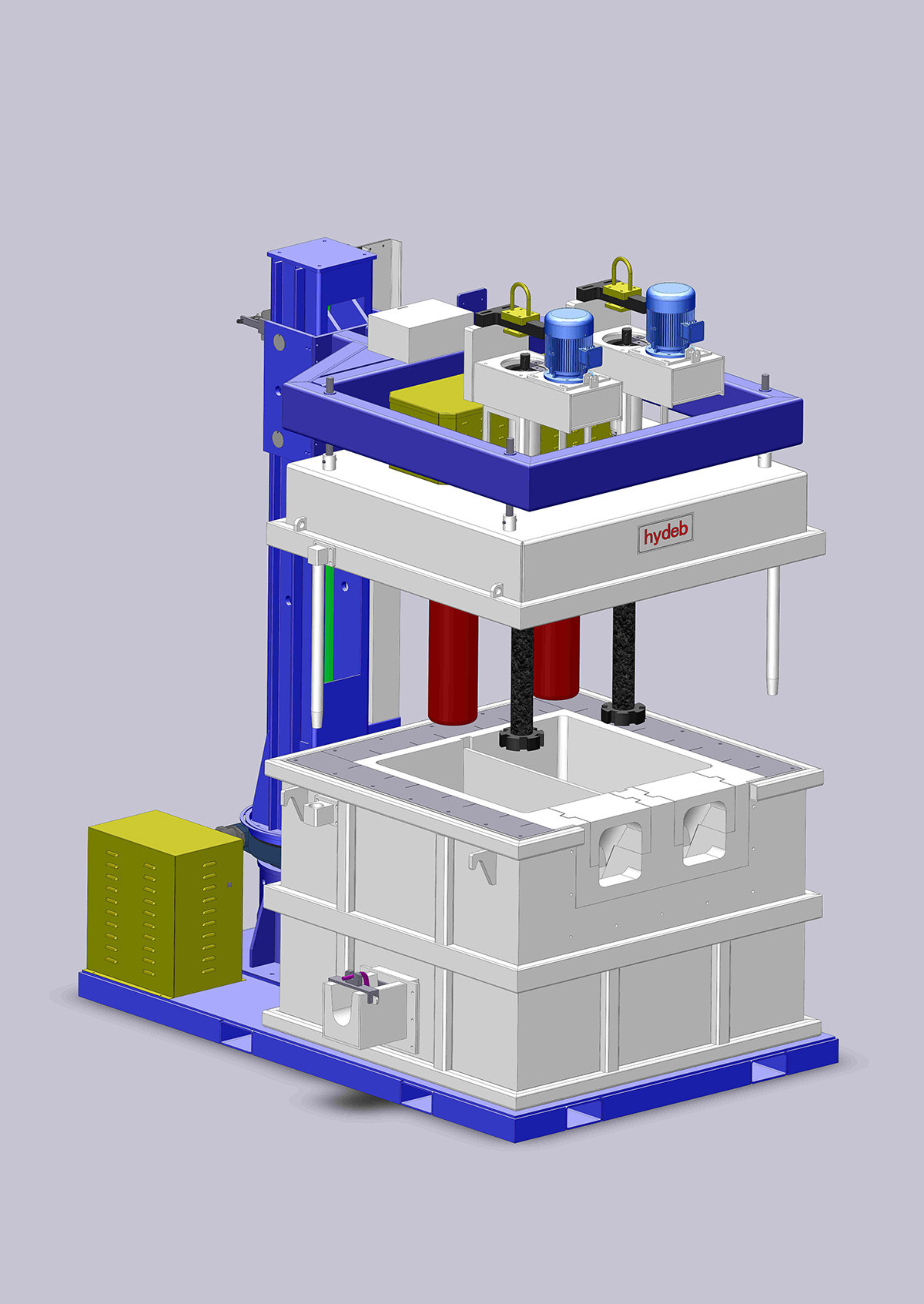

Casthouse Smelting And Casting Line In-Line Degassing System Unit For Billet Slabs Casting

1. Usage:

• Hydeb BDU Box Type In-line Rotor Degassing Unit is usually installed between the discharge outlet of the smelting furnace and the filter box. The molten aluminum flows into the box of the degassing unit and flows out from the outlet of the degassing unit, that is, realizing the purpose of continuous In-line refining.

• The rotor is rotated in the box to break the inert gas, forming a large number of dispersed bubbles into the molten aluminum, and with the gas floating, the hydrogen and oxidized slags in the molten aluminum will be brought out from the molten aluminum surface to achieve the purpose of degassing and refining.

• The BDU Box Type In-line Rotor Degassing Unit has been improved in many key points such as the box sealing, spare parts service life, and anti-turbulence on the surface of molten aluminum and so on, which will be ensuring the safe, high-efficiency, continuous and stable, and low-cost operation of the degassing device.

2. Equipment Features

• Degassing Efficiency Can Reach More Than 60%

-Optimum dispersion of the process gas in the molten aluminum

-The max. touch area and time between the dispersing bubbles and the molten aluminum

-The box is completely sealed to ensure a stable inert gas environment

-The molten aluminum surface is smooth without turbulent flow effect.

• Easy to Installation & Maintenance

-Simple replacement of the inner lining of the pre-fired forming degassing box minimizes production downtime.

• Low Maintenance & Operation Cost

-Long service life of heater and heater protection tubes;

-Long service life of rotor and shaft

-Cooling gas without rotor rotating main shaft.

3. Main parameters

| No. | Item | Parameters |

| 1 | Max. Temperature of Molten aluminum | 750℃ |

| 2 | Rated flow | 25T/h |

| 3 | Precision of molten aluminum temperature control (static) | ±2℃ |

| 4 | Molten aluminum heating ability | ≥20℃/h |

| 5 | Launder surface temperature rising | ≤40℃ |

| 6 | Service life of launder lining | ≥24 months |

| 7 | Continuous service life of heater | ≥3 months |

| 8 | Service life of heater protection tubes | ≥12 months |

| 9 | Continuous service life of rotor | ≥3 months |

| 10 | Rotor speed (stepless speed regulation) | 100-600rpm |

| 11 | Refining Gas | High-purity Ar or high-purity N₂: pressure 0.2-0.5 MPa, purity ≥99.996%, Water (ppm) ≤3, Oxygen (ppm) ≤5

|

| 12 | Degassing Efficiency | When it is not greater than the maximum flow rate, the inlet hydrogen content is ≤0.30ml / 100gAl, when the aluminum liquid is 700-740 ℃, the hydrogen content after degassing is ≤0.12ml / 100g Degassing efficiency≥60% when hydrogen content at the inlet>0.30ml/100g-Al. |

| 13 | De-alkalization Efficiency | Each alkali metal content<10ppm before refining, each alkali metal (Na, Li, Ca) content <2ppm after refining |

4. Equipment Pictures