|

|

[China]

Trade Verify

Address: No 35, Longhua Avenue, Airport Industry Area, Luoyang City, Henan Province, P. R. China, Luoyang, Henan, China

Contact name:Melinda

LUOYANG LIUSHI MOULD CO.,LTD |

|

Verified Suppliers

|

|

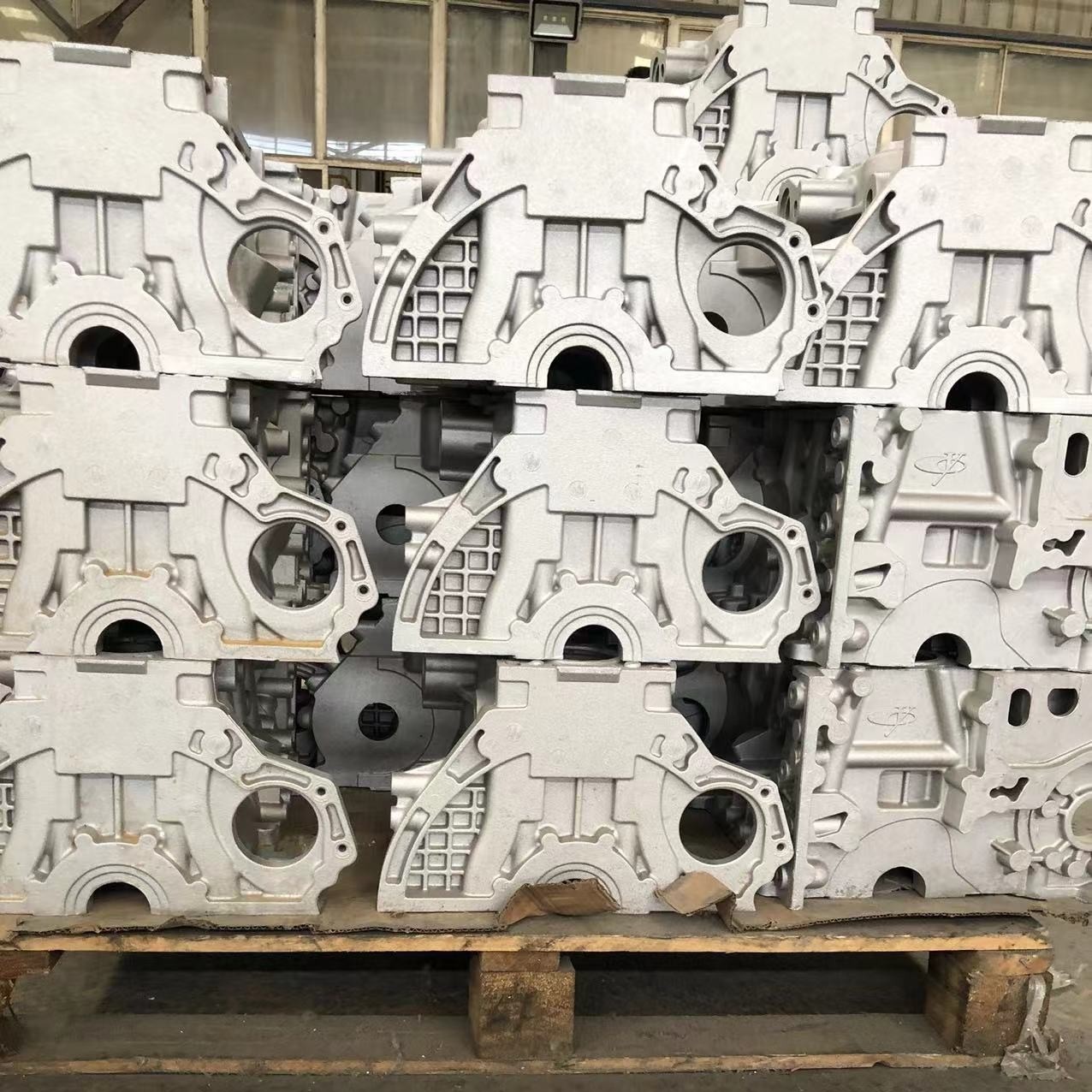

Aluminum Alloy Casting is a process for casting aluminum alloy materials with high precision tolerance. It is mainly achieved by Lost Foam Casting Process, Gravity Casting Process, Aluminium Alloy Casting Process and Precision Casting Process. The aluminum alloy materials can be machined with high accuracy and high efficiency by CNC Machining, Drilling, Milling, Turning and other processing technologies. The surface treatment of the Aluminum Alloy Casting products can be Polishing, Sandblasting, Anodizing and other treatments. The finished products can be packaged in Wooden Cases, Cartons, Pallets and other types of packages to ensure safe delivery. The Aluminum Alloy Casting process can achieve high precision tolerance of ±0.1mm-±0.5mm.

| Attribute | Parameter |

|---|---|

| Processing Technology | CNC Machining, Drilling, Milling, Turning, Etc. |

| Material | Aluminum Alloy |

| Heat Treatment | Annealing, Quenching, Tempering, Etc. |

| Packaging | Wooden Cases, Cartons, Pallets, Etc. |

| Surface Treatment | Polishing, Sandblasting, Anodizing, Etc. |

| Casting Method | Aluminium Alloy Casting Process, Lost Foam Casting Process, Gravity Casting Process, Die Casting Process |

| Tolerance | ±0.1mm-±0.5mm |

| Application | Automotive, Aerospace, Etc. |

| Inspection | 100% Inspection |

| Weight | 1-100kg |

Liushi aluminum alloy casting is the perfect choice for industrial applications due to its superior strength and durability. Our aluminum alloy casting process and manufacturing techniques adhere to the highest standards, and every cast is inspected to ensure 100% quality control. Our gravity casting process produces components with precise dimensions and a flawless finish, and our experienced technicians are able to create custom parts to fit any application. We offer a wide range of aluminum alloys, and our heat treatment processes, including annealing, quenching and tempering, guarantee excellent mechanical properties. Our team is able to work with a variety of drawing formats, including PDF, DWG, IGS, STP, and more, to create the perfect product for you. All of our aluminum alloy casting products meet the strictest quality standards, and come with a 16949 certification, and we accept orders of minimum 1000 pcs with TT payment terms.

Brand Name: Liushi

Place of Origin: Luoyang

Certification: 16949

Minimum Order Quantity: 1000 pcs

Payment Terms: TT

Tolerance: ±0.1mm-±0.5mm

Size: Customized

Packaging: Wooden Cases, Cartons, Pallets, Etc.

Material: Aluminum Alloy

Processing Technology: CNC Machining, Drilling, Milling, Turning,

Etc.

We provide customized services for Aluminum Alloy Casting, using the Lost Foam Casting Process. We guarantee high quality and precision of our products from Liushi, Luoyang, with certification of 16949. The minimum order quantity is 1000 pcs with payment terms of TT. The tolerance of our products is up to ±0.1mm-±0.5mm and we offer customized size. The packaging of our products can be Wooden Cases, Cartons, Pallets, etc. The material used for our products is Aluminium Alloy and the processing technology used is CNC Machining, Drilling, Milling, Turning, etc.

Aluminum Alloy Casting products are packaged in durable, secure cartons and shipped via a dependable, reliable carrier.

We use a variety of packaging materials depending on the size and shape of the part or product. Small parts may be wrapped in bubble wrap and placed in a small box, while larger parts are securely mounted in a larger box with foam inserts to keep them from moving during shipment.

We have a long-standing relationship with a number of carriers in our industry, so that we can ensure the safe and timely delivery of your Aluminum Alloy Casting products.