Dome Metals Co., Ltd. |

|

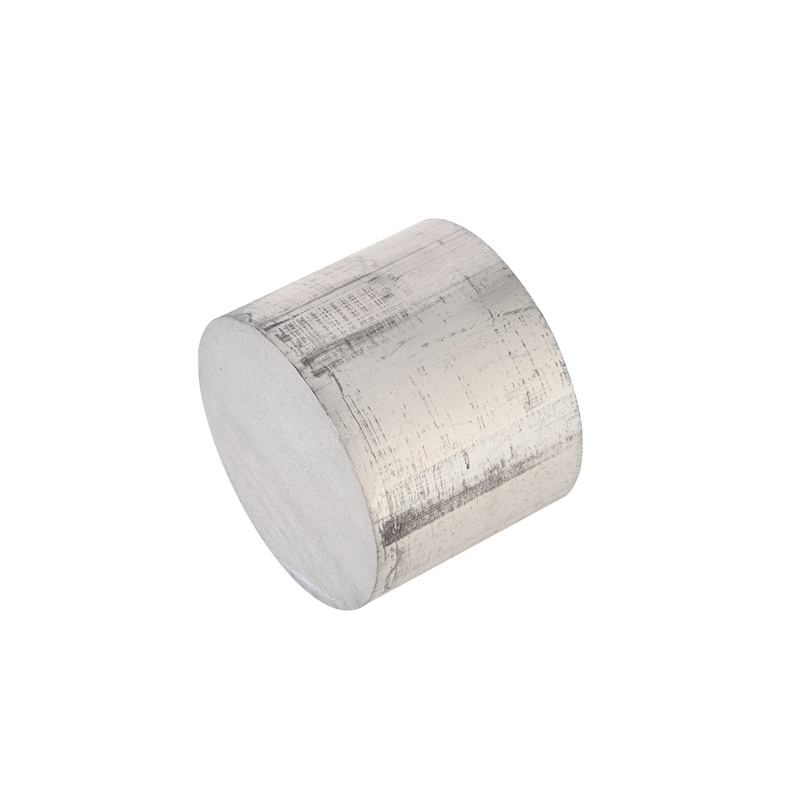

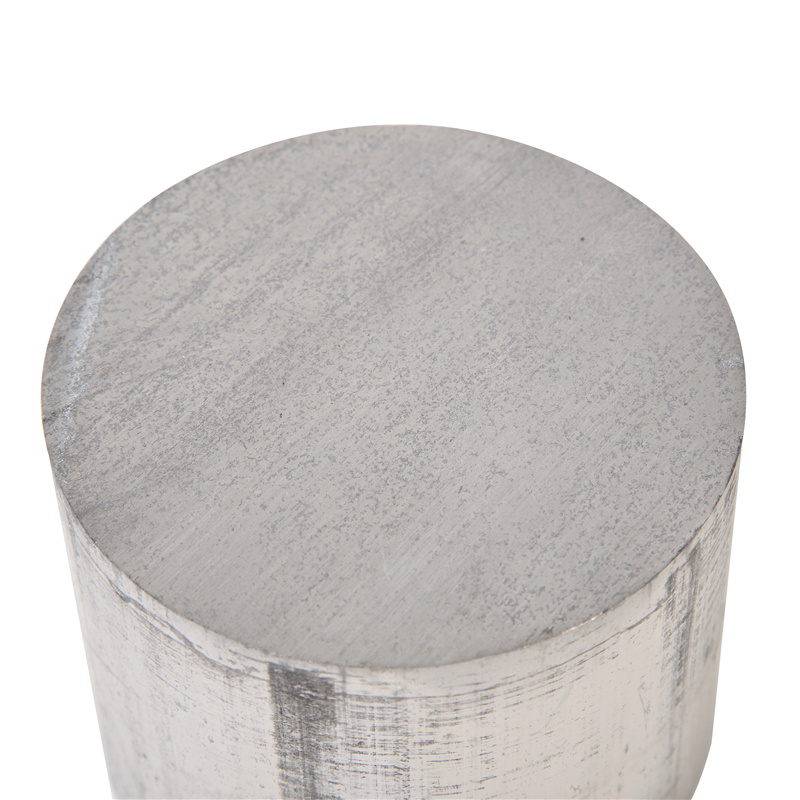

96-99% High Purity Extruded Magnesium Alloy Rod Extruded Bars

Mg ingot magnesium alloy bar in aerospace applications wholesales

1. Magnesium alloy Ingredients: Main material composition: AZ31B, ZK61M, AZ80A, AZ91D, M2M, ME20M, AZ40 other materials can be produced according to customer requirements.

2. Appearance: through the quality control of the layers of control, the company also requires packaging staff in the product packaging while controlling the appearance of the product is good. Carefully screened to ensure quality assurance.

Magnesium Alloy Bar Main Used for Balance weight, target, Military industry and so on. It is the lightest in the practical metal, high strength, high rigidity, and also has Good shock absorption performance.

Processing technology:

Compared with traditional magnesium alloy, Semi-continuous casting

has higher strength and extensibility on its organization and

composition.

1. Magnesium liquid pouring directly from the holding furnace and

making it rapidly crystallization by pipetting and twice refining

with high purity and less impurity. it can improve the compactness

of the inner metallurgical structure of magnesium rod and make its

a more reasonably inner densification crystallization. And the

physical nature is greatly enhanced comparing to the traditional

casting products.

2. The impurities in rhyolite even tends to zero in the molding product. semi continuous casting magnesium alloy adopts new inert gas protection device, which greatly reducing the amount of entrapped slag and improving the product quality . in the traditional process , the smelting process is completely exposed to the air, which can only inflaming retarding by rholite etc.

3. The surface is smooth and clean, no porosity, no shrinkage, no slag inclusion.

4. The length is flexible. Its existing maximum diameter is Φ600mm. it can be peeled, cut as customized. In addition, we also can produce other different specification product to meet customers’requirement. Various of specifications of magnesium ally flat bar can be semi continuous cast.