Dongguan Xinlong Non Woven Machinery Equipment Co., Ltd. |

|

Verified Suppliers

|

|

10KW Adoption Of Inverter Control Allows For Accurate Productivity And Production Speed Of One To Three Mask Machines

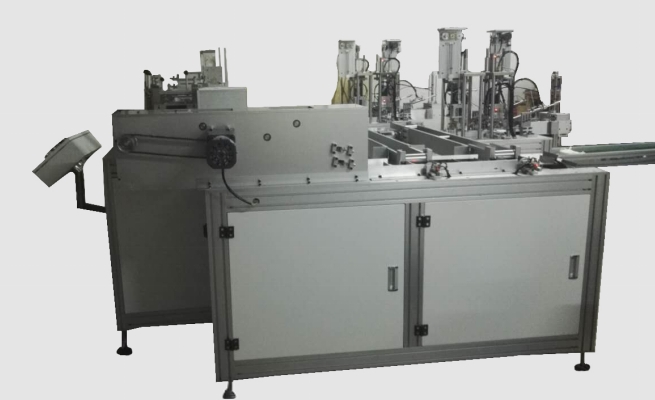

ONE TOW THREE MASK MAKING MACHINE PRODUCTION LINE

One tow three mask production line a body manufacturing machine and three sets of external ear band fusion machine connected, the mask body production is completed, respectively transferred to the three sets of external ear band fusion machine, ear band fusion, to complete a piece of mask production of all processes; the whole process to realize the full automation of the production process; only one operator can operate the entire production line.

The ONE TOW THREE MASK MAKING MACHINE PRODUCTION LINE produces masks with precise and consistent dimensions, ensuring a comfortable and secure fit for the users.It offers a high level of automation, reducing the need for manual labor and increasing overall production efficiency.

The ONE TOW THREE MASK MAKING MACHINE PRODUCTION LINE incorporates advanced sensors and quality control mechanisms to ensure the production of masks that meet high standards.

This production line is equipped with an automatic material feeding system, ensuring a continuous and uninterrupted production process.This production line is designed to comply with relevant safety and quality standards for mask production.

1. This machine mask fully automatic output, ear strap fusion welding machine without rotating work, automatic interactive processing system built-in to ensure stable output of masks;

2. This machine adopts computer programmed control, photoelectric detection, which can automatically detect the failure of the whole machine or any one of them, improve the operability of the machine and reduce the failure rate of the machine;

3. The machine adopts frequency conversion control to accurately control the production efficiency and production speed;

4. Compared with semi-automatic equipment, this machine is more efficient, more humanized, and more aspects of operation, solving the labor problem of mask industry.

5.This production line incorporates a self-diagnostic system that alerts operators to potential issues, allowing for timely maintenance and troubleshooting.

6.It can be integrated with other equipment, such as a mask sterilization machine or a packaging machine, for a complete mask production and packaging line.

7.The ONE TOW THREE MASK MAKING MACHINE PRODUCTION LINE offers customizable options for mask printing, allowing for the addition of logos, labels, or other branding elements.

MACHINE CHARACTERISTICS:

| Machine size | 4300(L)*4500(W)*1800(H)mm |

| Line source | 220V ,1 Phase |

| Production capacity | 120 Pcs/min |

| Power | 10KW |

Our advantage

SCALE ADVANCED PRODUCTIVITY

The company has gathered a group of experts who have been engaged in production site maintenance, operation control, and machine debugging for many years. With experienced staff. For long-term operation of industrial equipment due to disturbance Difficulties and frequent detects, production and design put forward solutions, let the solutiongs in the design Stages are field-tested to maximize the effectiveness of the solution at the lowest cost.

PROFESSIONAL R&D TEAM

At the beginning of its establishment, Xinlong started to cultivate a professional R&D technical team, always pay attention to the latest development in the field of non-woven fabrics, and closely track new technologies at home and abroad. The R&D team has been accumulating for many years and has maintained professinoal sensitivity.

EQUIPMENT MANUFACTURING TEAM

The company has gathered a group of staff with many years of rich exerience. Aiming at some difficulties and frequent defects that have caused long-term disturbance to the operation of equipment in the industry, production and design propose solutions, allowing the solution to undergo on-site inspection during the design stage, so that the solution can achieve the strongest effectiveness and the lowest cost.