Foshan Nanhai Huashi Decoration Material Ltd. |

|

Verified Suppliers

|

|

The aluminum plastic board is an amalgamation of two entirely disparate materials - metal aluminum and non-metal polyethylene plastic. These two distinct substances, when joined together, produce an incredibly strong and long-lasting material with a multitude of outstanding features.

These features range from opulence, eye-catching colour variation, weather resistance and collision protection, to fire and moisture resistance, sound and heat insulation, and an earthquake-proof structure. Furthermore, it is lightweight, very easy to mould and relatively effortless to install and move. These attributes make the aluminum plastic board an ideal choice for several practical purposes.

Featherweight: Aluminum composite panels have an elevated strength-to-weight ratio compared to traditional aluminum and steel sheets. The area weight of aluminum composite panels is almost 60% of aluminum sheets and just 30% of steel sheets, while maintaining a similar stiffness.

Exceptional Cohesion: The adhesion between the aluminum sheet and the plastic core material is so strong that there is no unaided separation between the two after a long period of service.

Weather Endurance: After being exposed to outdoor weather, aluminum composite panels retain their original color and gloss level. The coatings also don't drop off, making their average life expectancy more than twenty years.

Resistance to Corrosion: Aluminum composite panels have the highest adhesion strength surface layer, making them extremely resistant to acid, base, salt spray, and corrosive effects. Plus, the PVDF fluorocarbon resin coating is hard to damage.

Withstands Wind Load: Aluminum composite panel performance can achieve the national A grade level, satisfying the wind load resistance requirements for tall building exteriors.

Flame-Proof: The center layer of aluminum composite panels is non-toxic polyethylene, and both sides are thin and inflammable aluminum plates.

Our company's aluminium composite panels can be conveniently shaped and processed using ordinary woodworking and metalworking tools. This involves techniques such as cutting, sawing, milling, punching, pressing, folding, and bending which all provide a precise execution of the diverse forms needed by architectural decoration designs. Especially when it comes to shapes such as arcs, counter-arcs, and small-radius corners, both internally and externally, it's clear to see that this product offers a lot more versatility than other decorative materials.

More specifically, it can be cut and shaped using tools such as electric saws, hand saws, and so on. Slot milling allows for manual bending into many kinds of polyhedrons. Corners can be removed using a corner removing machine combined with a puncher. The product can be welded using plastic welding rods and hot wind welders, bent into various corners with a slot milling machine, and 3-point and 3-rolling machines, and printed using screen printing plates. Furthermore, it can also be assembled with items like rivets, nails, and self-tapping screws, as well as punched using an open puncher.

Urban exteriors are widely used across various sectors. It is utilized as cladding on towering structures, suburban homes, corporate complexes, and commercial high-rises – offering an aesthetically appealing finish. Its application goes beyond this, incorporated in decorating home interiors, work spaces, and business zones. This includes wall cladding, creative ceiling patterns, and space dividers.

The urban exterior is also used in the advertising sector. They are employed for large advertising boards, shop displays, wayfinding signs, digitally printed banners, and promotional stages. Aside from this, other popular usages come in the form of vehicle parts construction for public and private transport means such as buses, trains, metros, aircraft, and marine vessels.

Urban exteriors are also implemented in designing furniture, wardrobes, kitchen worktops, and other indoor fixtures in residential spaces. It extends to industrial deployments as well, applied in industrial plants as casing for machinery, protective shielding for devices, and applications in cleanrooms. Retail stores also take advantage of the urban exterior, utilized in the formation of kiosk blueprints and interior display units.

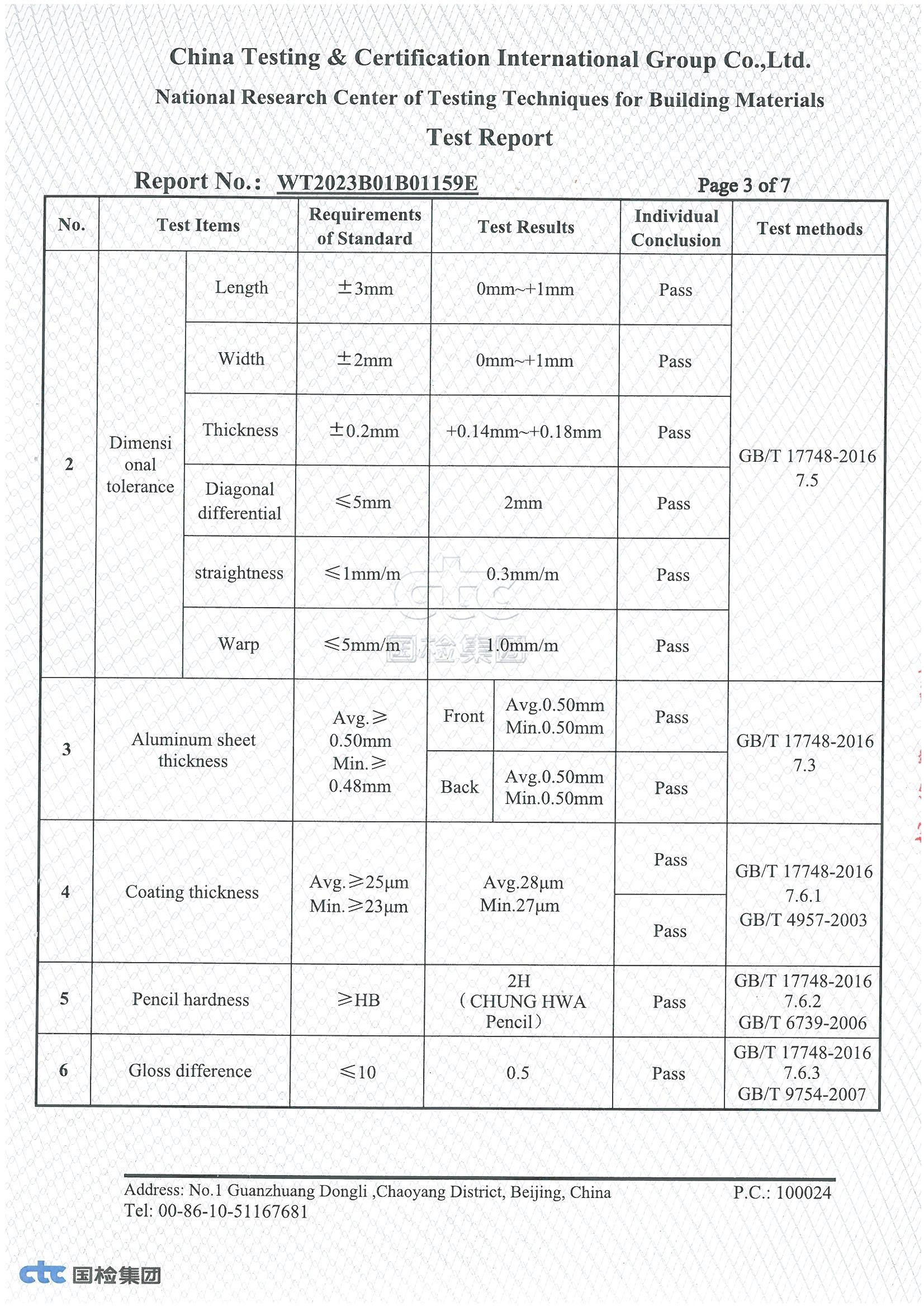

A1: PE Aluminum Composite Panel is a high-strength aluminum composite panel made by Richly Bound. It has passed ISO 9001:2008;GB 8624-2012;GB/T 17748-2016 certification and has the characteristics of light weight, corrosion resistance, fire retardant, etc.

A2: The minimum order quantity for PE Aluminum Composite Panel is 1500 square meters.

A3: The price of PE Aluminum Composite Panel is based on product specifications.

A4: PE Aluminum Composite Panel is made in China.

A5: The advantages of PE Aluminum Composite Panel include light weight, corrosion resistance, fire retardancy, good formability, and excellent weather resistance.