Foshan Nanhai Huashi Decoration Material Ltd. |

|

Verified Suppliers

|

|

ACP Plastic Sheet with 0.3mm Aluminum, Solid Color, for Renovation of Old Buildings, ACP Aluminium

An aluminum plastic panel is a composite building material that is composed of two aluminum sheets sandwiching a non-aluminum core. Beneath this core, there are also PVDF or PE coatings, which give a wide array of colors and finishes to the panel.

Apart from being used in combinations with architectural purposes, aluminum composite panels have many other uses, like external shop facades, advertising signboards, and in some interior decorations.

Thanks to their durability, lightweight, and formability, these panels are very popular in the current global market. Moreover, their recyclability and energy-efficiency further increase their value, as sustainability is an emerging trend in the modern world.

Featherweight: Exhibits an elevated strength-to-weight ratio. With similar stiffness (E.j), the areal weight of aluminum composite panels is nearly 60% of that of aluminum sheets and a scant 30% of steel ones.

Exceptional Cohesion: Demonstrates a high 180° peel strength. Over prolonged service, there is no unaided separation between the aluminum sheet and the plastic core material.

Weather Endurance: After extensive outdoor exposure, there's negligible alteration in color and gloss, no shedding of the coating, and the average life expectancy exceeds twenty years.

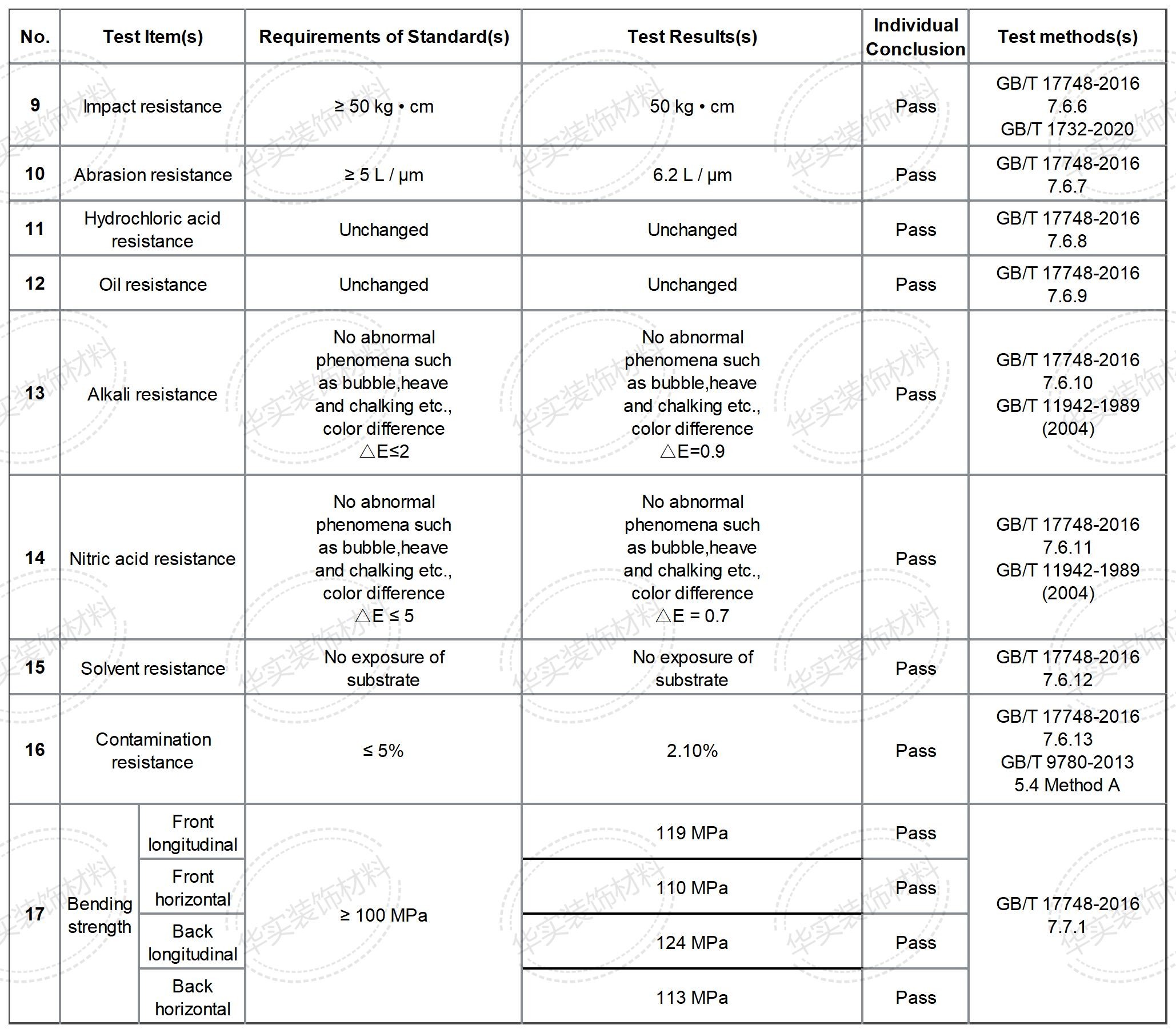

Resistance to Corrosion: The surface layer shows high adhesion strength and can counter the corrosive effects of acid (10%H2SO4), base (10%NaOH), and salt spray; the PVDF fluorocarbon resin coating is exceptionally resilient.

Withstands Wind Load: The performance level achieves national A grade, adhering to the wind load resistance prerequisites for tall building exterior decorations.

Flame-Proof: The interior layer is comprised of non-toxic polyethylene, and its two sides are thin, non-inflammable aluminum plates.

External Architecture: Utilized for external coverings on skyscrapers, standalone residences, business offices, and commercial buildings.

Inner Decoration: Used for interior ornamentation in households, office spaces, and commercial areas, involving wall accents, ceiling schemes, and room dividers.

Promotional Displays: Implemented for billboards, store signage, direction indicators, digital advertisements, and display stages.

Transit Infrastructure: Used in the formation of parts for buses, trains, metro systems, airplanes, and nautical vehicles.

Interior Design: Utilized for crafting furniture styles, wardrobes, kitchen cabinet faces, and other indoor installations.

Industrial Implementations: Utilized in production facilities as protective covers for machinery, safety casings for equipment, and sterile room uses.

Consumer Facing Designs: Incorporated in the design of retail stores, kiosk layouts, and indoor display segments.

Using typical woodworking and metalworking tools, the aluminium composite panels manufactured by our company can be effectively processed and molded. Operations such as cutting, sawing, milling, punching, pressing, folding, and bending can be undertaken with ease. This makes it possible to create various forms with precision that are needed in architectural decoration design, specifically for shapes like arcs, counter-arcs, small-radius corners, and internal and external corners. Such a high level of adaptability is unprecedented in other decoration materials.

1. Cutting: Cutting tool, electric saw, hand saw, ring saw, etc.

2. Slot Milling: After processing with an electric and portable

slot milling machine, the product can be manually bent into various

kinds of polyhedrons.

3. Corner Removing: After processing with a puncher and corner

removing machine, it can be combined in a trunk.

4. Welding: The product can be welded with plastic welding rods and

hot wind welders.

5. Corner Bending: After processing with a slot milling machine,

the product can be bent into various corners.

6. Bending: The product can be bent using 3-point or 3-rolling

machines.

7. Printing: The product can be printed with screen printing

plates.

8. Assembling: Rivet, nail, self-tapping screw, etc.

9. Punching: The product can be punched with an open puncher.