Liaoyang Zhonglian Pharmaceutical Machinery.,Ltd |

|

Verified Suppliers

|

|

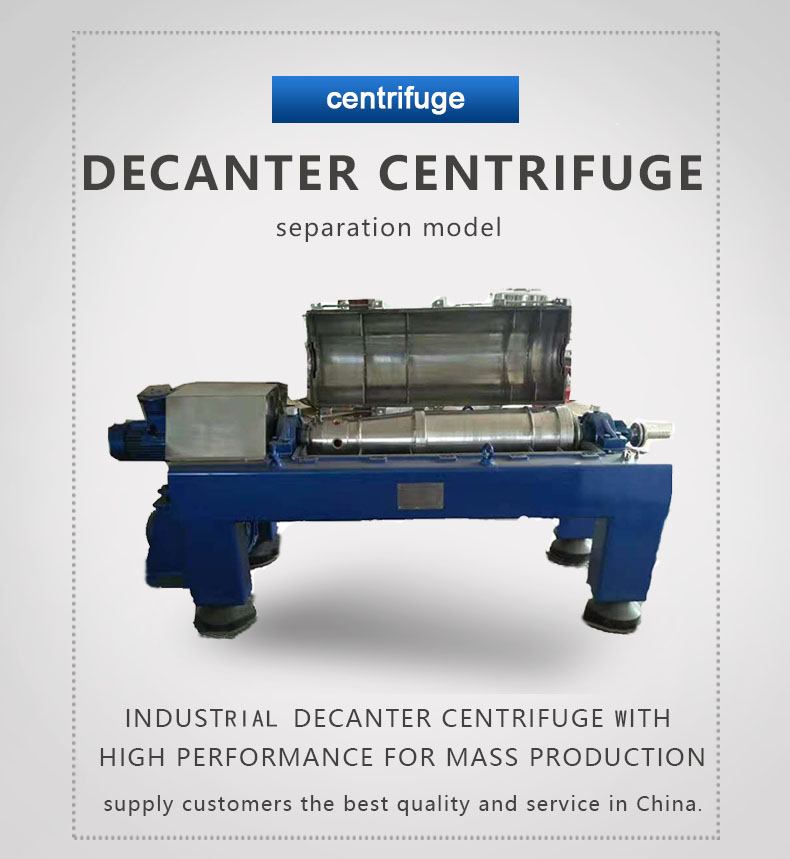

industrial scale oil extractor 3 phase separation decanter centrifuge 3 phase tricanter

Model | Drum diameter mm | Length mm | Maximum speed rpm | Hightest separation factory/g | Mixture capacity m3/h | Motor Power Kw | Host weight Kg | Dimension (L*W *H) mm |

LW250-900 | 250 | 900 | 5000 | 3500 | 0.5-3 | 11/5.5 | 1100 | 2300*700*1300 |

LW350-1500 | 350 | 1500 | 3800 | 2850 | 1-5 | 18.5/5.5 | 2200 | 3500*1000*1300 |

LW400-1200 | 400 | 1200 | 3400 | 2581 | 1-8 | 22/7.5 | 2200 | 3350*1000*1100 |

LW400-1600 | 400 | 1600 | 3400 | 2581 | 2-10 | 22/7.5 | 2400 | 3850*1000*1250 |

LW400-1800 | 400 | 1800 | 3400 | 2581 | 2-12 | 22/7.5 | 2500 | 4000*1000*1250 |

LW450-1800 | 450 | 1800 | 3200 | 2572 | 5-20 | 30/7.5 | 3000 | 4200*1170*1350 |

LW450-2000 | 450 | 2000 | 3200 | 2572 | 5-25 | 30/7.5 | 3300 | 4400*1170*1350 |

LW530-2280 | 530 | 2280 | 2800 | 2350 | 10-50 | 45/15 | 4000 | 4750*1300*1500 |

LW600-2400 | 600 | 2400 | 2600 | 2265 | 15-65 | 55/18.5 | 5000 | 4800*1350*1950 |

LW650-2600 | 650 | 2600 | 2400 | 2100 | 20-80 | 55/90 | 6500 | 4900*1450*1650 |

LW720-2500 | 720 | 2500 | 2200 | 1950 | 25-90 | 75/90 | 7000 | 5000*1600*1700 |

LW800-2560 | 800 | 2560 | 2000 | 1800 | 30-100 | 90/132 | 8000 | 4600*2200*1400 |

LW800-3200 | 800 | 3200 | 2000 | 1800 | 30-110 | 90/132 | 9000 | 5200*2200*1400 |

LW900-3200 | 800 | 3200 | 1800 | 1650 | 30-150 | 132/200 | 10000 | 5500*2300*1800 |

Industry | Success case |

Food processing | Edible animal fat |

Plant oils such as olive oil and vegetable oil | |

Wine (clarification) | |

Fruit juice | |

Soy protein | |

Dairy (recovery of lactose, whey fines and cheese fines) | |

Coffee and tea | |

Petrochemical/oil | Refining |

Dewatering | |

Oil well drilling | |

Lubricating oil additives | |

Waste oil stream recycling | |

Industrial and biological wastewater treatment | Municipal wastewater |

Cleaning of wash water | |

Fish processing | Fish meal |

Fish oil | |

Chemical | Herbal medicines |

Chemical extraction | |

Mineral processing | Bentonite and titanium dioxide manufacturers |

Kaolin clay and calcium carbonate processing | |

Organic chemical industry | Organic intermediate and end products |

Polymer Industry | Thermoplastics for example PVC, synthetic rubber and fibres |

Inorganic chemical industry | Bleaching agents |

Acids | |

Silica products | |

Fertilisers |