Yuan Xin electrician material (Hongkong) Co., Ltd. |

|

SYNTHITE®43Polyester coating,SYNTHITE®AC-46 Mould proof coating for PCB SYNTHITE®AC-41,

AC - 43 as a kind of high temperature resistant, 43 modified multivariate polyester at room temperature and dry type any standing water.

Product features

1. The UL certification to the level of CLASS F insulation system.

2. Rapid drying.

3. High penetrability.

4. Strong binding force.

5. Good connectivity.

6. Rapid processing.

7. Excellent thermal and acid and alkali.

8. Excellent toughness and ductility.

Product use:

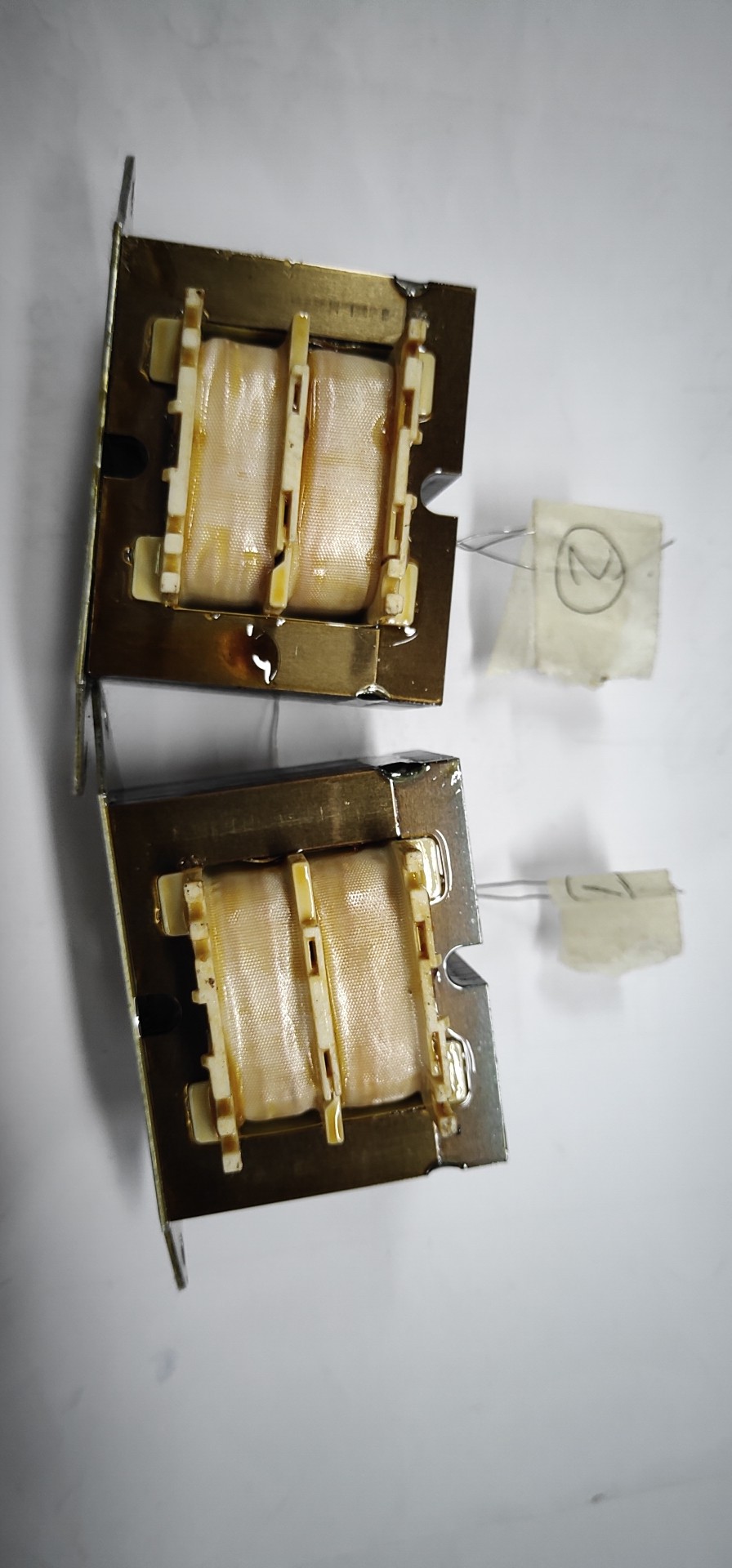

Both electrical and electronic products and parts, various types of coils, transformers, PC circuit board, resistor, capacitor generators, etc

Directions for use

43 can be applied to AC - containing leaching, brush method and spray method and so on the many kinds of processing, may be placed on a natural dry in the air,

Can also be through baking to increase its oil resistance and chemical resistance. General processing process just under 110 ℃ temperature for 1 hour

Can complete, if you would like to shorten the baking time to bake at 148 ℃ temperature for 10 ~ 15 minutes and AC - 43

After baking in products covered a layer of thin film in order to increase the creek and connectivity.

If the automation process of the operating system proposed:

Please put all the temperature needed for baking equipment to warm up to components

1. With the temperature of 100 ℃ preheat first 10 minutes.

2. Cooling and 60 ℃.

3. The product submerged proposition that made the water, about 15 seconds until bubbles disappear.

4. The product drip dry about 45 seconds.

5. In the oven to bake for about 5 minutes under 148 ℃.

In this process when processing, it is recommended that the blending with 15% thinner than the case study is used, but still need to make appropriate adjustments according to the product characteristics

Excellent water resistance:

Excellent acid sulfuric acid (10%)

Excellent alkali resistance (1% sodium hydroxide)

Resistant to salt water: excellent

Through the oil resistance, ASTM D - 115

Storage:

Store in a cool and dry environment (suggested 18 ℃ ~ 24 ℃), and away from direct sunlight

Shelf life: 1 year (save in temperature under 21 ℃)

Packing and marking

1, packing: 5 gallons barrel 55 gallon barrel

2, a barrel products before they go out all paste identification card, indicate the product name, batch, etc, so that the quality of tracking;