Effemax global industrial co.,limited |

|

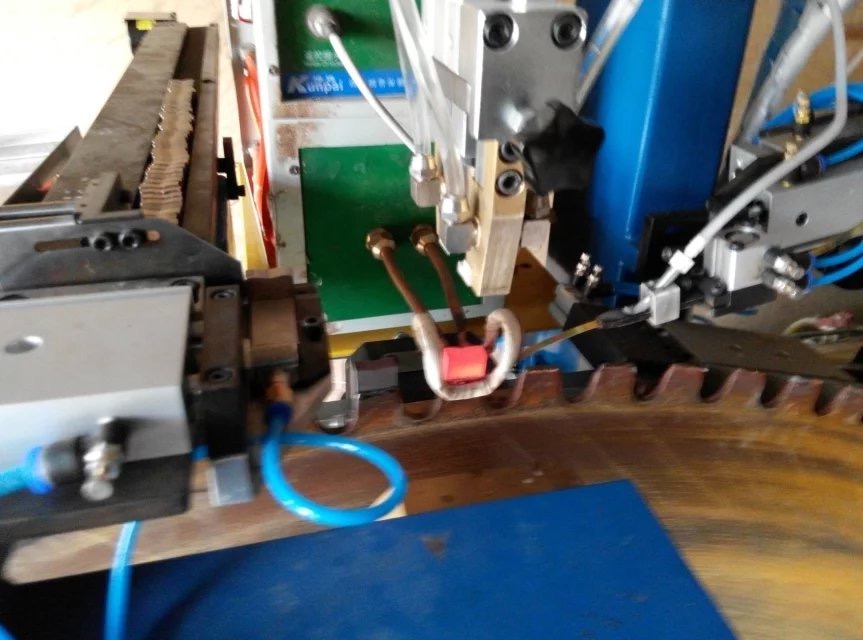

auto feed wire PLC control diamond segments automatic brazing frame

This machine uses touch screen control and HMI operation, automatically control of welding time, equipped with tank photoelectric detection system, positioning and rotating saw blade body and feed segment and wire automatically, high accuracy positioning, feed wire second time for last tooth to ensure the welding strength. Bilateral independent fans to improve cooling speed, automatic alarm display for easy troubleshooting. It can complete welding process automatically and easy to operate.

Features

Segment and saw disc automatic centering

Configure water tank photoelectric system, automatic positioning saw blade and automatic alarm for fault running

Adjustable for R/F segments, L/T segments, brazing time, cooling time, brazing tooth number, skip brazing according to actual demand.

Automatic feeding solder, brushing flux, automatic centering,at the last segment, it will feed solder two times to ensure the end teeth brazing strength

With touch screen control and HMI operation

Easy to operate and maintaince

Applicate for brazing segments for stone cutting saw blade

Process

The process of electric induction brazing is shown and explained while watching the machine in action that automates parts of this process, with the aid of manually pushing buttons at the right time and manually adding necessary materials for the brazing of the diamond blade to be completed. Diamond blades are used for cutting materials that are especially tough to cut through, such as stone, concrete or asphalt. Segments eventually wear out with heavy use and then need to be replaced to make the blade effective again for cutting through tough materials. This video shows the process of soldering new diamond segments around the outside edge of a large blade.

After stripping it, will clean it with an air sander, it is important that the surface is clean when soldering so all will bond to it, now it will go through the heat cycle, 24 seconds, segment gets red, not it is going through the cooling cycle, the indexer, clamp the blade, then it will go through the cycle again, add flux, solder won’t stick without the flux, placing segment, heating both sides at the same time, put less heat on the blade, good consistency for the segment, minimal segment loss.

Specification

| Name | Unit | Data |

| Welding Diameter | mm | Φ800-3200 |

| Welding Verticality Tolerance | mm | ±0.03 |

| Welding Capacity | pc/h | 180-460 |

| Air Pressure | mpa | 0.6 |

| Hydraulic Pressure | mpa | 0.2 |

| Power | w | 1400 |

| Water consumption | m³/h | 1.5 |

| Voltage | V | 220V/50Hz |

| Weight | kg | 320 |

Size | mm | 1100×1050×2500 |

High frequency induction heater

Features:

High frequency voltage option: 220V, 380V, 415V, 440V

Automatic tracking working frequency, good adaptability to inductor

Low working frequency and high power, good heat permeability

With protection function of overvoltage, overcurrent, overheat, lack of water, lack of phase etc.

Specification

| Name | Data |

| Voltage | 220V/50Hz |

| Work voltage range | 160V/250V |

| Output power | 20kW |

| Max vibration power | More than and equal to 20kW |

| Vibration frequency | 50-150KHz |

| Efficiency | 90% |

| Cooling water flow rate | 5L/Min (0.2Mpa) |

| Cooling water pressure | 0.2-0.3Mpa |

| Water temperature protection point | 50 degree |

| Dimension | 460x190x380 |

| Load duration | 100% |