Effemax global industrial co.,limited |

|

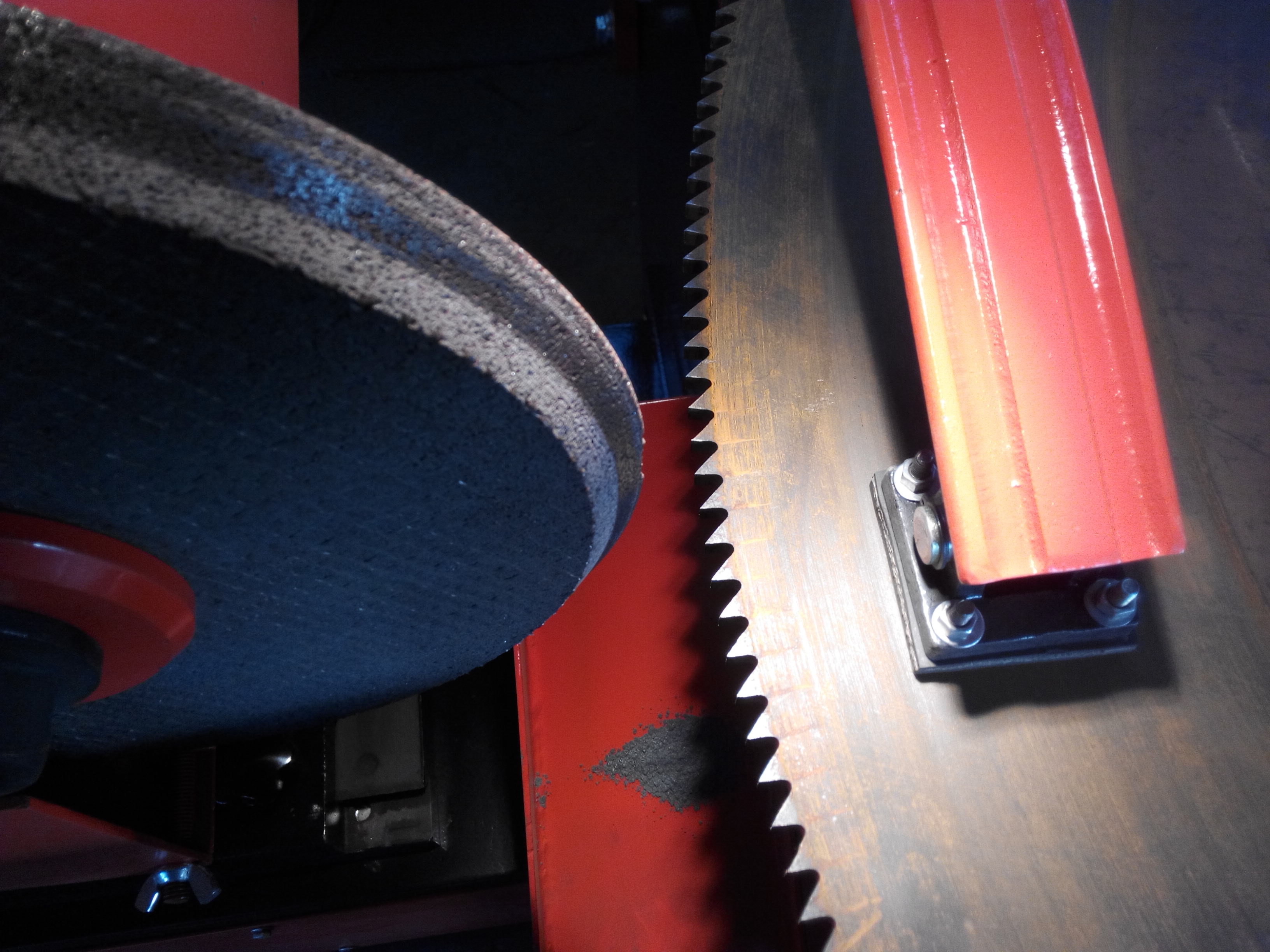

Metalic round saw blade teeth grinding automatic sharpening machine

Description

High efficiency saw blade grinding machine is a new generation of high efficiency grinding machine independently developed based on many years of field experience and combined with advanced foreign technology. Two characteristics: high efficiency and accuracy. The equipment can meet the requirements of repairing the saw blades used in bar and section steel production line.

Application field :saw blade manufacture, iron and steel plant saw blade regrinding and repairing, steel tube and pipe manufacture regrinding and repairing.

Parameter:

| Name | Data |

| Saw blade diameter range | 1000-2200mm |

| Saw blade thickness | 6-18mm |

| Power supply volatge | AC380V/50Hz |

| Air source | 0.5-0.9Mpa |

| Air sourse pressure | 0.5-1.0Mpa |

| Working pressure | 0.6Mpa |

| Power of motor | 4 KW |

| Power of control | 0.5KW |

| Grinding speed | 15-25 teeth |

| Diameter of ginding wheel | 250mm |

| Main machine size | 2200x1400x1150mm |

| Electric cabinet size | 1100x540x300mm |

Please provide the blade diameter, center hole (bore), the number of teeth, tooth depth,

pitch and other data before inquiry.

The grinding wheel moves in the vertical direction:

New grinding mode: the axial force generated by grinding wheel offset by bearing under saw blade, at this time, the push rod push against the saw teeth, due to friction of presser, the saw teeth are not easy to generate pendulum, the grinding precision improved accordingly.

Advantages

Drive control

The saw blade teeth pusher and grinding wheel feed action are controled respectively by cylinder, the sawtooth can be ground once in place, greatly improve the efficiency of saw blade teeth regrinding.

As the wheel feed stroke is adjustable (to reduce the non-effective stroke), due to push the teeth and grinding wheel feed speed adjustable (to reduce the non-effective grinding time), so the effective grinding time of the entire work cycle of 60% -80%

New grinding mode: the axial force generated by grinding wheel offset by bearing under saw blade, at this time, the push rod push against the saw teeth, due to friction of presser, the saw teeth are not easy to generate pendulum, the grinding accuracy improved accordingly.

Electric control

The machine will not start if the grinding wheel position is not correct, the operator can adjust the saw teeth pitch and position and then start the grinding wheel. With four sets position sensor, could detect position of grinding wheel and saw teeth push rod. Saw teeth number could be set and machine will stop running after grinding as set, and there is sound and light alarm. Quantity of repaired saw blade could be accumulated. Grinding speed could be adjusted according to saw blade diameter, teeth profile and teeth depth.

Machine structure

T