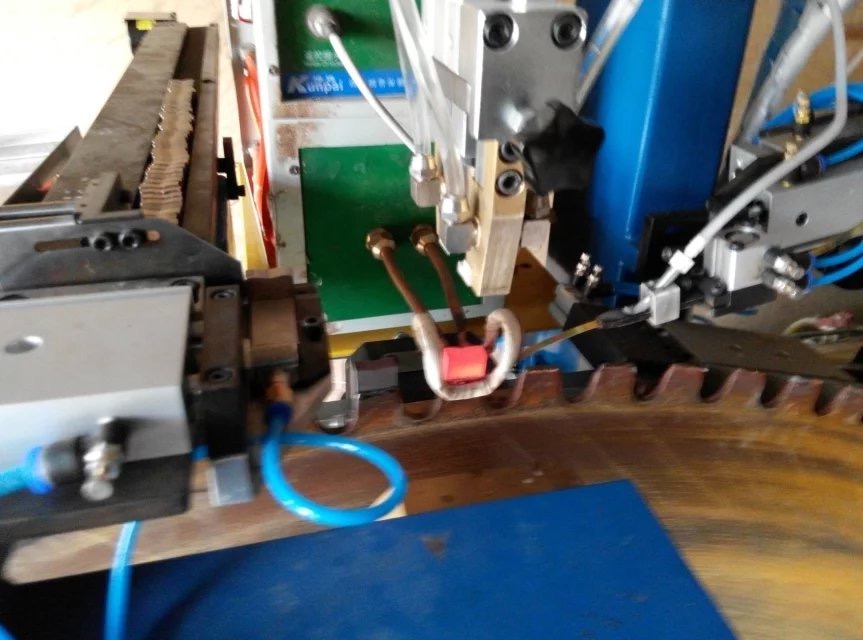

Diamond tools company efficient diamond segments auto control

welding machine

This machine uses touch screen control and HMI operation,

automatically control of welding time, equipped with tank

photoelectric detection system, positioning and rotating saw blade

body and feed segment and wire automatically, high accuracy

positioning, feed wire second time for last tooth to ensure the

welding strength. Bilateral independent fans to improve cooling

speed, automatic alarm display for easy troubleshooting. It can

complete welding process automatically and easy to operate.

Features:

Segment and saw disc automatic centering

Configure water tank photoelectric system, automatic positioning

saw blade and automatic alarm for fault running

Adjustable for R/F segments, L/T segments, brazing time, cooling

time, brazing tooth number, skip brazing according to actual

demand.

Automatic feeding solder, brushing flux, automatic centering,at the

last segment, it will feed solder two times to ensure the end teeth

brazing strength

With touch screen control and HMI operation

Easy to operate and maintaince

Applicate for brazing segments for stone cutting saw blade

Automatic Welding Lifting Rack for Diamond Saw Blades

This equipment is a kind of automatic large welding rack, who

welded together with diamond segments and saw blades’ body by high

frequency welding. The device is mainly suitable for welding

diamond saw blades of 800-3200mm.

Functions and Features:

1. Pneumatic push tooth, automatic alarm display for running the

fault.

2. The parameters of related R/F-segment, L/T-segment and saw,

welding time, welding gear, cooling time, skip welding, can be

adjusted according to actual needs.

3. High degree of automation, high positioning accuracy,

automatically sending segment, automatically feeding solder wire,

automatic brushing flux.

Specification

| Name | Unit | Data |

| Welding Diameter | mm | Φ800-3200 |

| Welding Verticality Tolerance | mm | ±0.03 |

| Welding Capacity | pc/h | 180-460 |

| Air Pressure | mpa | 0.6 |

| Hydraulic Pressure | mpa | 0.2 |

| Power | w | 1400 |

| Water consumption | m³/h | 1.5 |

| Voltage | V | 220V/50Hz |

| Weight | kg | 320 |

| Size | mm | 1100×1050×2500 |

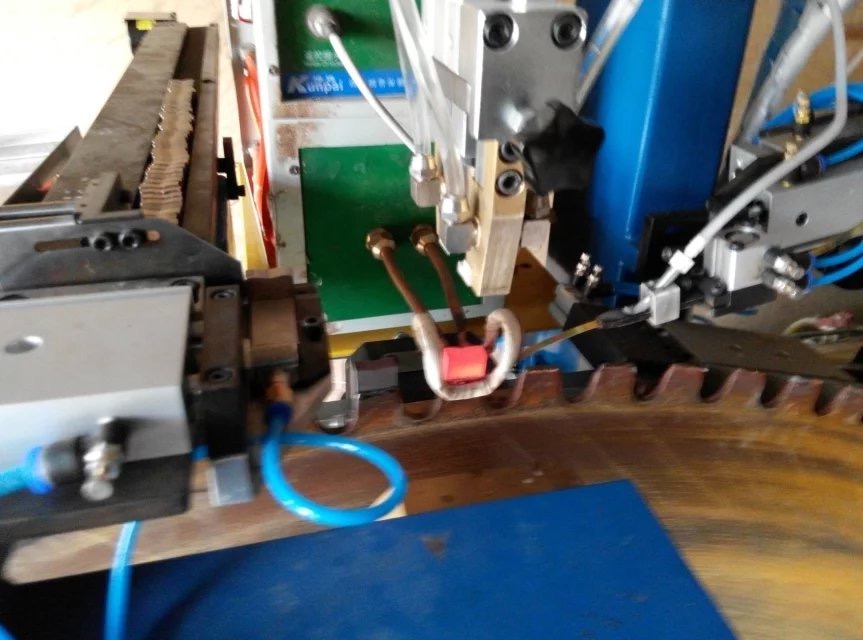

Automatic Welding Lifting Rack for Diamond Saw Blades

This automatic welding machine is mainly used for welding segments

on tooth of diamond steel core with diameter from 800-2200mm.

Features

Push tooth by pneumatic cylinder, automatic alarm for fault running

Adjustable for R/F segments, L/T segments, welding time, cooling

time, welding tooth number, skip welding according to actual

demand.

Automatic feeding solder, feeding segments, brushing flux,

positioning with high accuracy

With touch screen control and HMI operation

Easy to operate and maintaince

Applicate for welding segments for stone cutting saw blade

Specification

| Name | Unit | Data |

| Welding Diameter | mm | 800-2200 |

| Verticality | mm | ±0.03 |

| Welding capacity | Pc/h | 180-460 |

| Air pressure | Mpa | 0.6 |

| Water pressure | Mpa | 0.2 |

| Power | W | 1200 |

| Water consumption | m3/h | 1.5 |

| Size | mm | 1000x950x2445 |

| Voltage | V | 220 |

| Weight | kg | 270 |

Automatic Welding Lifting Rack for Diamond Saw Blades

This machine uses touch screen control and HMI operation,

automatically control of welding time, equipped with tank

photoelectric detection system, positioning and rotating saw blade

body and feed segment and solder automatically, high accuracy

positioning, feed solder second time for last tooth to ensure the

welding strength. Bilateral independent fans to improve cooling

speed, automatic alarm display for easy troubleshooting.

Features

Segment and saw disc automatic centering

Configure water tank photoelectric system, automatic positioning

saw blade and automatic alarm for fault running

Adjustable for R/F segments, L/T segments, welding time, cooling

time, welding tooth number, skip welding according to actual

demand.

Automatic feeding solder, brushing flux, automatic centering, at

the last segment, it will feed solder two times to ensure the end

teeth welding strength

With touch screen control and HMI operation

Easy to operate and maintaince

Applicate for welding segments for stone cutting saw blade

Specification

| Name | Unit | Data |

| Welding Diameter | mm | 280-1100 |

| Verticality | mm | ±0.03 |

| Welding capacity | Pc/h | 250-700 |

| Air pressure | Mpa | 0.6 |

| Water pressure | Mpa | 0.2 |

| Power | W | 1200 |

| Water consumption | m3/h | 1.5 |

| Size | mm | 1000x810x1550 |

| Voltage | V | 220 |

| Weight | kg | 230 |