Hunan Xunzhuo Imp.&Exp. Co.,Ltd |

|

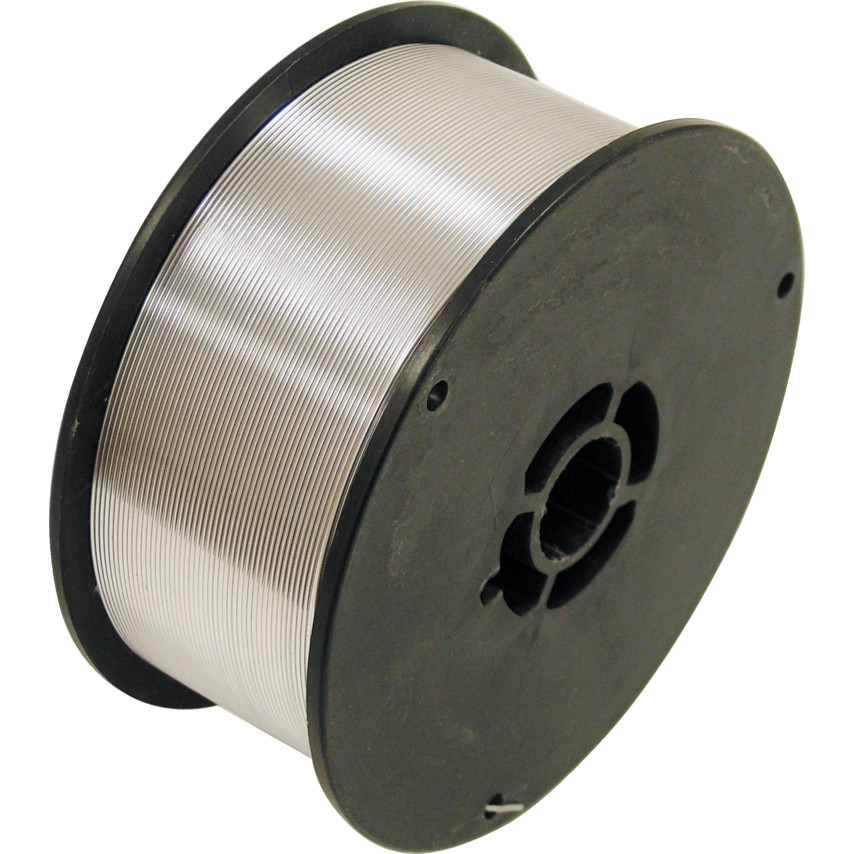

Name:TIG Aluminium Welding Wire welding rod Er 4047

Description

Er4047is widely used in general welding material with the magnesium

of 5% and a little of titanium fine grains.And this product is of

high toughness,

Good forgeability, and well anti corrosiveness, furthermore, this

is a good choice for colormatch in welding after anodic process.

The model er4047 do not suggested to use in aluminum alloy

workpiece which working temperature is over 65ºc,thus will cause

corrosion cracking in welded

Joints.You should strictly clean the oxide film on the edge of the

workpiece and oil before welding, otherwise it will make bad weld

produce and cause porosity,

Slag inclusion and other defects.Also you can use a plate to hold

molten metal to ensure meld form.

MIG wireSpecification : 0.8mm;0.9mm;1.0mm;1.2mm;1.6mm Weight : 6kg/7kg/9kg per spool

TIG wire Specification : 1.6mm;2.0mm;2.4mm;3.0mm;4.0mm;5.0mm Weight : 5kg/10kg/20kg per box

| Chemical component(wt)/% |

Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Be |

| Al | ||||

| 4.5~6.0 | 0.8 | 0.3 | 0.05 | 0.05 | _ | 0.1 | 0.2 | _ | 0.0003 | Rem. |

Characteristic |

Melting range | 1065 - 1170°F |

| Electrical conductivity | 42%IACS(O) |

| Density | 2.68g/mm3 |

| Anti corrosion performance | B(Gen) A(SCC) |

| The coefficient of thermal expansion (20 degree ~300 degree ) | 22×10-6/K |

| Thermal conductivity (20 degree) | 170W/m@K |

Welding reference parameters(Current polarity:MIG:DC+ TIG:AC)

| MIG | Welding wire diameter(mm) | 1.2 | 1.6 | 2.0 |

| Welding current(A) | 180-300 | 200-400 | 240-450 | |

| Welding voltage(V) | 18-26 | 20-28 | 22-32 | |

| TIG | Welding wire diameter(mm) | 1.6-2.5 | 2.5-4.0 | 4.0-5.0 |

| Welding current(A) | 150-250 | 200-320 | 220-400 |

| AWS Code | chemical composition(%) | |||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | |

| ER1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.06 | 0.03 |

| ER1100 | 0.95 | 0.95 | 0.05-0.20 | 0.05 | - | - | 0.10 | - |

| ER4043 | 4.5-6.0 | 0.80 | 0.30 | 0.05 | 0.05 | - | 0.10 | 0.20 |

| ER4047 | 11.0-13.0 | 0.80 | 0.30 | 0.15 | 0.10 | - | 0.20 | - |

| ER5356 | 0.25 | 0.40 | 0.10 | 0.05-0.20 | 4.5-5.5 | 0.05-0.20 | 0.10 | 0.06-0.20 |

| ER5183 | 0.40 | 0.40 | 0.10 | 0.5-1.0 | 4.3-5.2 | 0.05-0.20 | 0.25 | 0.15 |

| ER5556 | 0.1 | 0.3 | 0.05 | 0.55-8.0 | 4.7-5.2 | 0.05-0.10 | 0.09 | 0.05-0.10 |

Application

The argon arc welding of aluminum & magnesium alloy welding

wires is used as the filler material, widely used in welding among

al/mg/si, almasilalloy and

Aluminium & magnesium alloy, like:Bicycles, aluminum scoter,

etc.Engine carriage, pressure vessel, armory processing,

shipbuilding.Space shuttle etc.

Top Features

Packing details:

Mig wire-0.8mm/0.9mm/1.0mm/1.2mm/1.6mm/2.0mm

D300 6-7kg/spool (0.8mm-1.6mm)

D270 5-6kg/spool (0.8mm-1.6mm)

D200 2kg/spool (0.8mm-1.2mm)

D100 0.5kg/spool (0.8mm-1.2mm)

Tig rod-1.6mm/2.0mm/2.4mm/3.2mm/4.0mm/5.0mm/6.0mm

1000mm length 5kg/box (1.6mm,2.0mm,2.4mm,3.0mm)

1000mm length 10kg/box (3.2mm,4.0mm,5.0mm,6.0mm)

Outer packing:1spool/ctn

Every spool product is strongly packed by carton box with antirust

paper inside.

Container load:84spool/pallet , 22pallets/20ft (based on

6-7kg/spool)

Company information:

our factory is a 14 years aluminum welding materials manufacturer in China. Our Mig&Tig aluminum alloy welding wires and rods are selling very well in both domestic and oversea market. If any new inquiry, please feel free to contact us, we'd like to offer our latest price.

Our Service:

1. Strict quality control.

2. Best price offer.

3. On-time delivery.

4. Sample offered.

5. OEM and ODM accepted

Attention