Zhengzhou The Right Time Import And Export Co., Ltd. |

|

Straight Line Automatic Edge Banding Machine With Rough And Fine Repair Function

Edge banding is an important process in the manufacturing process of panel furniture. The quality of edge banding directly affects the quality, price and grade of the product. Through edge banding, the appearance quality of the furniture can be well improved, and the transportation and use of the furniture can be avoided. During the process, the edges and corners are damaged, the veneer layer is lifted or peeled off, and at the same time, it can play the role of waterproof, seal the release of harmful gases, reduce deformation, etc., but also beautify the furniture and make the mood happy. The raw materials used by panel furniture manufacturers are mainly Particleboard, medium density board and other wood-based panels, the selected edge strips are mainly PVC, polyester, melamine and wood strips, etc. Edge strips of different materials and specifications need to use different edge banding equipment.

| Name | Straight Line Automatic Edge Banding Machine With Rough And Fine Repair Function |

| Model | ZDS-468 |

| The main function | Gluing, End trimming, Rough trimming, Fine trimming, Corner rounding, Scraping, Buffing |

| Working pressure | 0.6Mpa |

| Panel thickness | 10-60mm |

| Edge thickness | 0.4-3mm |

| Min. panel | 300*60mm 150*150mm |

| Voltage | 380V-3HP |

| Power | 13kw |

| Weight | 1600kg |

| Dimensions | 5800*900*1600mm |

PLC intelligent control, independent liquid crystal display can see the running process of the machine more clearly and comprehensively, which is convenient, quick and easy to use, real-time monitoring, real-time adjustment, more accurate, high-efficiency production, and the edge sealing effect is not compromised.

The gluing system is used to apply the glaze melt glue on the edge of the workpiece. The gluing and edge-sealing device makes the edge-sealing plate and the edge-sealing material evenly gluing through a special mechanism to ensure stronger adhesion. , the glue will be melted in the glue melting container, the glue roller will transfer the hot glaze glue to the workpiece by rotating, and the quantitative device will control the supply amount and adjust the distance between the glue application shaft and the workpiece.

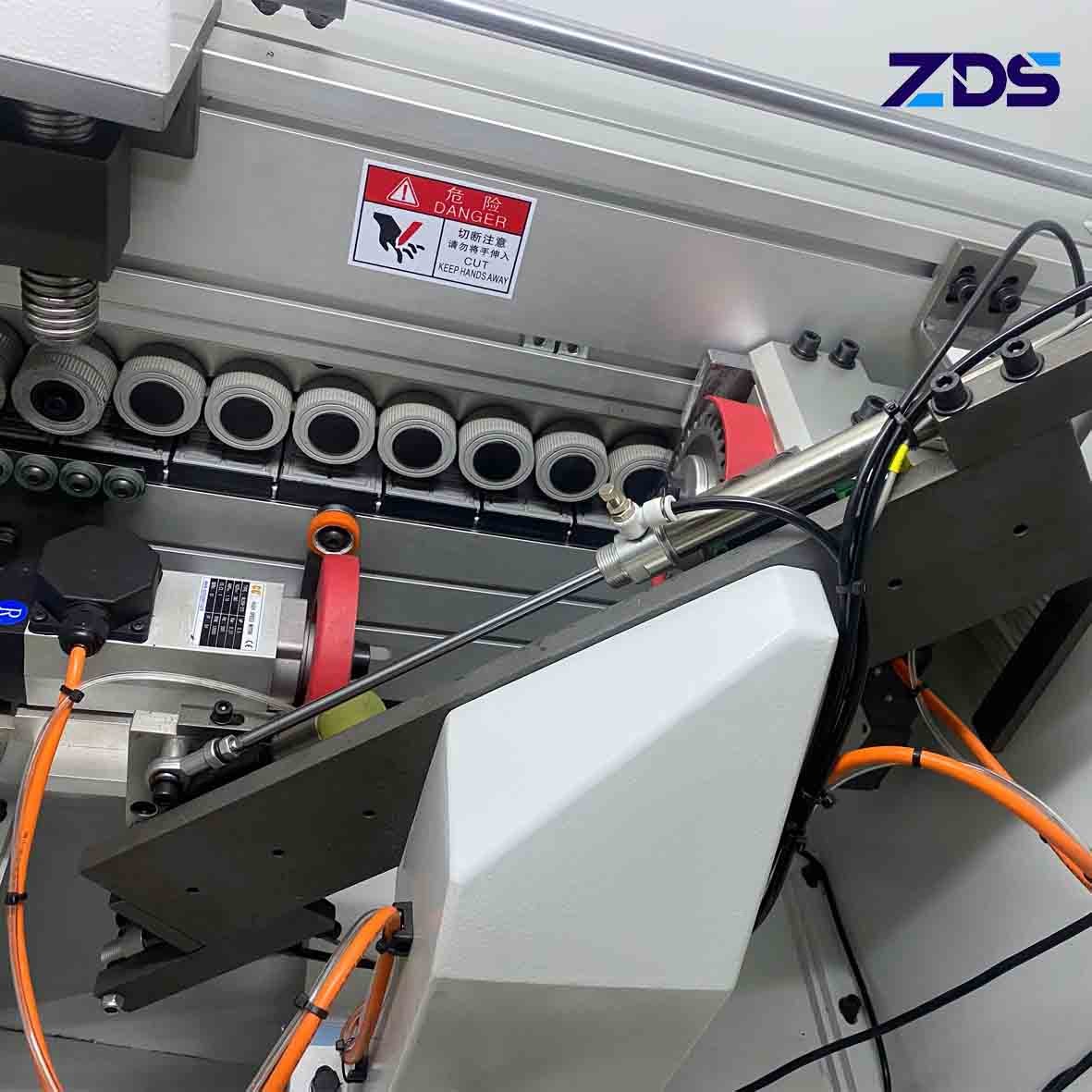

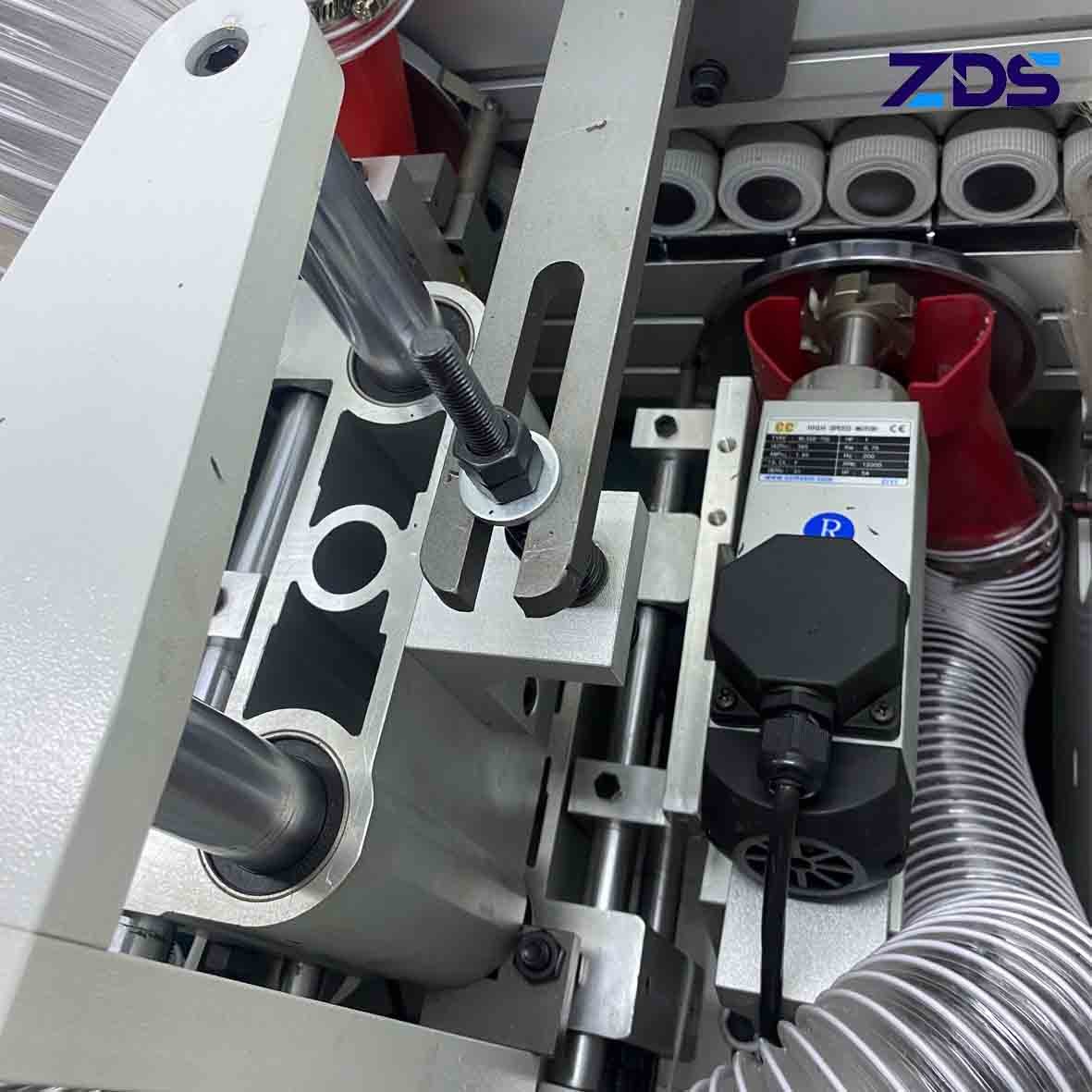

The end trimming system is used to cut off the cutting components that exceed the front and rear end laminations. The flush device moves through precise linear guides, and adopts mechanisms such as automatic mold tracking and high-frequency electrode rapid cutting to ensure that the cut surface is smooth and smooth. The cutting unit is used for sawing of super high sections of lamination. The edges are right-angled or beveled by rotation, both of which are done by scraping the edges. A cutting assembly consists of two unrelated cutting units.

Rough trimming device, the cutter at the rough trimming part is a flat knife, which is used to trim the excess edge sealing material on the upper and lower parts of the edge banding of the processed sheet.

Finishing device, the finishing knife is R2 inclined knife, which can leave 5-6 wire allowance for the next scraping process. The automatic tracking of the mold and the high-frequency motor are used to achieve fast cutting, and the R2 inclined knife is used to repair the radian.

Scraping device, profile scraping, is used to eliminate the secondary wave marks caused by the cutting process of non-linear motion of trimming, so that the upper and lower parts of the plate are more smooth and tidy. better.

The polishing device cleans the processed plate with a cotton polishing wheel, removes excess glue stains, and makes the edge banding section smoother and tidy through polishing.