Foshan Hold Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Woodworking Edge Banding Machine, All Intelligent Control System,

Narrow panel edge bander HD623

Narrow panel edge bander

This equipment is suitable for the edge banding of customized

furniture companies, especially for processing narrow panels with a

width of 35mm-60mm. It can replace the manual processing mode of

narrow panels, solving the problem of narrow panel edge sealing in

factories.

Narrow-sided panel≥35mm

Feeding support device + Automatic side press device

The machine frame is welded with a high-strength structural steel panel, with high strength and stability, and the surface is rust-proofed and high-temperature lacquer;

Electrically adjustable lifting press beam, touch screen control, reduce labor intensity, improve efficiency and accuracy;

Four pressing wheels with an enlarged diameter and four air cylinders ensure that the edge band is tightly pressed on the workpiece;

Conveyor reducer is strong and powerful;

Technical Parameters

Model | HD623 | Model | HD623 |

Lifting | Electrical lifting | Panel thickness | 10-60mm |

Total power | 10.3kw | Panel length Panel width | Narrow side≥45mm |

Overall size | 5195x900x1700mm | Working pressure | 0.6Mpa |

Feed speed | 14-20-23m/min | Min.sheet size | 35x300mm(Long side) |

Edge thickness | 0.4-3mm | Min.sheet size | 45x300mm(Narrow side) |

Configuration instructions

| Control System |

| Auxiliary feeding of narrow side end |

| Narrow side automatic side pressing device |

| Electric pres beam lifting

Touch screen control eliminates the trouble of manual height adjustment. |

| EVA gluing system

The glue quantity is controlled reasonably. The thermal conductivity is good. The operation is stable. The coating is even. The adhesion is firmer, and the edge sealing effect is perfect. |

| Glue removal unit

Strong pressing force, fit edge banding, removing residual hot melt adhesive on board to minimize glue thread and make edge banding optimal. |

|

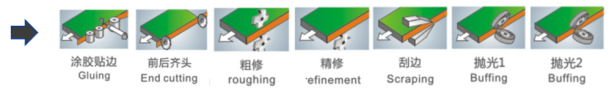

End cutting

Quickly cut the front and back edge banding. The two saw blades are matched back and forth to achieve high precision and high efficiency.

|

| Rough trimming

Cut the upper and lower edges of the edge banding strip quickly and neatly to make the edge banding effect better. |

| Fine trimming

Cutting and shaping the excess edge on upper and lower panel and trimming into an R-angle shape, the upper and lower edges will be flat to the panel and smooth. |

| Scraping

Remove the knife marks left by the trimming knife and the refined R fillet |

|

|

| Harden geared motor

4.0kw power, stable operation. |

| Unique design: rubberized supporting wheel

The front and rear auxiliary rollers are equipped with rubber-covered rollers to prevent scratch. |

More video to know about our machines and company.

About our company

One-stop solution for interior furniture equipment and wooden door

equipment

HOLD Machinery was founded in 2004, focusing on the development of

a full range of furniture machinery equipment and wooden door

machinery and equipment, providing furniture and wooden door

enterprises with solutions for whole factory planning and

automatical production lines, providing customers with excellent

quality, efficient and stable products, and high-quality service.

HOLD Machinery has served the majority of furniture and wooden door

enterprises in more than 40 countries and regions around the world

and has won wide admiration from customers.

FAQ:

1. Do you have the machine in stock?

Sorry, we don't have the machine in stock, edge banding machine has

many options such as voltage, speed, function, and so on, So it's

hard to prepared samples.

2. How long is your delivery time?

For our standard model, the delivery time is around 1.5~2 months.

For the customized model, the delivery time is around 2~3 months.

It depends on the client's project and quantity.

3. Do you have a factory?

Yes, we have our own factory and we promise direct sales at a

competitive price. Welcome to visit our factory at any time.