Dongguan HOOHA Electrical Machinery Company Limited |

|

Highly Speed Wire Extrusion Machine Silicone Cables And Wires Production

Application

It is for Silicne gel to extrude for silicone cable / wire and silicone hose .

it can match with Horizontal silicone

extruder to produce two color silicone cable .

line speed is about 120-150 m/min in our local market

1. Pay off stand (flexible to choose its type) ,

2. straighter ( for copper wire ) ,

3.silicone extruder machine ,

4.Laser cable diameter tester

5.curing chamber ( 20 meters ) ,

6.Printing machine ( for logo /specification on the cable )

7.accumulating ( for accumulate silicone cable when its speed is fast )

8. Capstan

9.Power powder machine ( for cable strip easily ) ,

10.Sparker ( On-line test cable’s quality ) ,

11.Take up machine ,

12.PLC electricity control panel .

| Parameters | 45 | 65 | 80 | 90 | 115 |

| Finished diameter | 0.8-4.0mm | 1.2-8mm | 2.0-16mm | 3.0-25mm | 8.0-50mm |

| Line speed (max.) | 170m/min | 150m/min | 120m/min | 80m/min | 50m/min |

| Extrusion output (max.) | 40kg/h | 90 kg/h | 150 kg/h | 200 kg/h | 300 kg/h |

| L/D | 12:1 | 12:1 | 12:1 | 12:1 | 8-12:1 |

| Extruder power | 7.5KW | 11KW | 22KW | 30KW | 55KW |

| Payoff reel | PN400-630 | PN400-630 | PN500-630 | PN630-800 | PN800-1250 |

| Curing length | 16m | 16m | 24m | 24m | 32m |

| Capstan power | 3.7KW | 5.5KW | 5.5KW | 7.5KW | 11KW |

| Take-up reel | PN400-630 | PN400-630 | PN500-630 | PN630-800 | PN800-1250 |

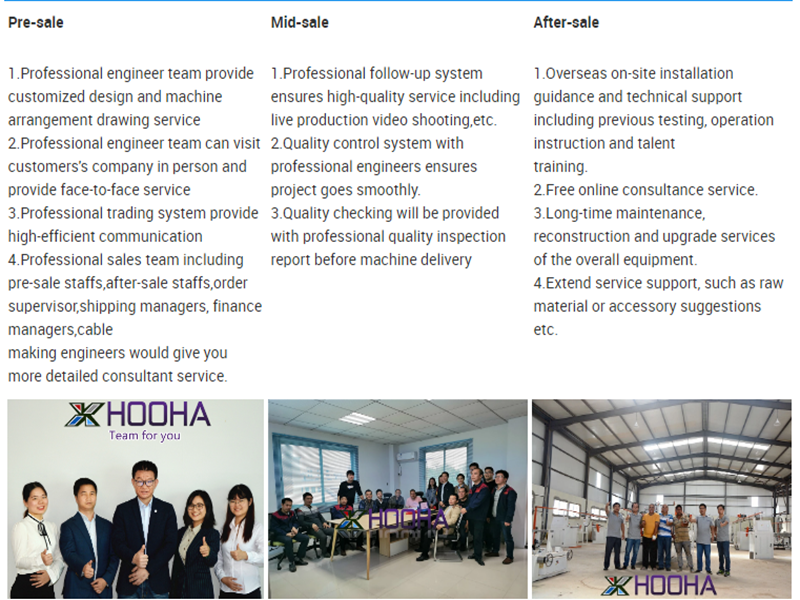

Q:What is your company after-sales service to support customer ?

Pre-sale training: In order to guarantee the customers fully to operate the machine, if the customer need, we can help customer training, includes

1)Correct operating mode

2)Correct maintenance way

3)Remove simple problem of our product

Since the shipment date,our company freely assuring period of after-sale maintenance service is

1)1 year for mechanical part

2)12-15 month for electrical part

offer lifetime consultation on problems occurred

We do house inspection for every machine before loading it,and also inspected by buyer in person.

About the machine production we have our own responsibility system,we label his name on the devices that he produced , each part has his name and they sign the document when machine test.Final the manager sigh his name when machine test well . so that the product reach to customer’s factory are good to use

Q:How is your service to customer?

A:1.It is able for us to offer customer the pre-sale services of providing customized design the production line based on special requirement of products, as well as configuring the production plant drawing of equipment arrangement if necessary, and accessing the factory environment.

2.We are able to provide service of training the customer's technicians in operation the machine and technical support in making wire and cable.

3.About after-sale services, we have obligation to offer installation and commissioning service in customer's factory.

4.The regular maintenance and product tracking service will be done in machine lifetime. Any problem can be feedback to our company pointed service man at any time, and the solution is going to be given with high quality and efficiently.

FAQ