Hebei Junke Machinery Technology Co.,Ltd |

|

Verified Suppliers

|

|

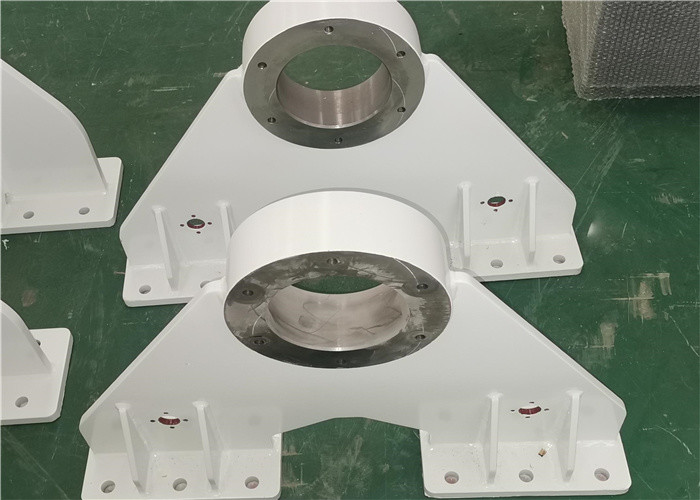

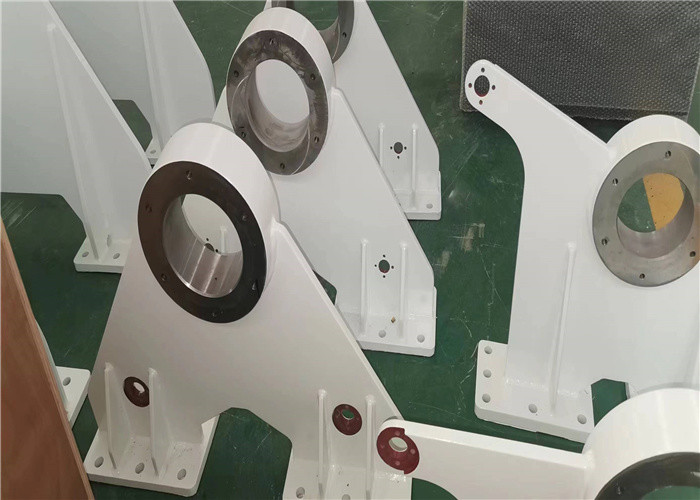

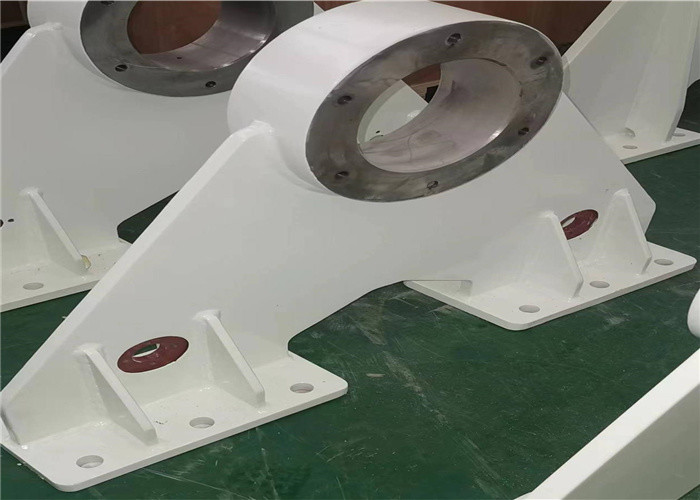

Product name: Q355D Marine Crane Equipment Parts Bracket -Bearing For Winch Rope Lifing And Down

Other name: Marine Winch bracket-bearing.

Standard: NS-ISO 2768mK

Sling type: cable or wire

power: Electirc

colour: Inerthane 990 Blue white

Rope: 100-1000mm

Rope diameter: 3-199mm

Tolerance General: NS-ISO 2768mK

Our company mainly serves lifting machinery, marine machinery, petroleum machinery, water conservancy machinery, We can produce winches and all steel parts for winches.

| Q/TY | ITEM | DESCRIPTION | TECHNICAL DESCRIPTION | MATERIAL | MASS | |

| 1 | 1 | Plate | PL30 | S355J2+N | 146.68KG | |

| 2 | 2 | Plate | PL25 | S355J2+N | 11.23KG | |

| 1 | 3 | Plate | PL25 | S355J2+N | 18.63KG | |

| 1 | 4 | Plate | PL20 | S355J2+N | 18.63KG | |

| 2 | 5 | Plate | PL20 | S355J2+N | 4.25KG | |

| 1 | 6 | Tube square | w300* H300 *T12 *L1250 | S355J2H | 26.26KG |

No parts shall be let unwelded unless clearly tsated on the drawing, for efficient and easy access it is recommended that sharp edges (that are not to be welded) are rounded to minimum R2.5 before assembling parts.

To ensure sufficient adhession for surface treatment all sarp edges shall be rounded to minimum R2.5, welding spatter beads and slag shall be completely removed, damaging in surfaces shall be filed and grinded flush, negative thickness measurements are prohibited.

Test temperature and charpy V-notch impact energy shall be in accoradance with DNV lifting appliances No.2.22. values for plates in primary and essential welded steel structure is listed in table below:

| Yield stress Re(MPa) | Thichness(mm) | temp(°C) | Impact energy(J) |

| 355 | 6< t ≤ 25 | 0 | 34 |

| 25< t ≤ 50 | -20 | 34 | |

| 50< t ≤ 70-40 | -40 | 41 | |

| 70< t ≤ 150 | -40 | 50 | |

| 690 | 6< t ≤ 25 | 0 | 46 |

| 6< t ≤ 25 | -20 | 46 | |

| 50< t ≤ 70 | -40 | 46 |