Guangdong Blue Whale Ultrasonic Equipment Co;Ltd |

|

Verified Suppliers

|

|

Blue Whale 0-2400W Industrial Ultrasonic Cleaning Machine 175L 28Khz or 40 khz Two Tanks Cleaner

1. What is the ultrasonic cleaning? Some general knowledge about ultrasonic cleaning.

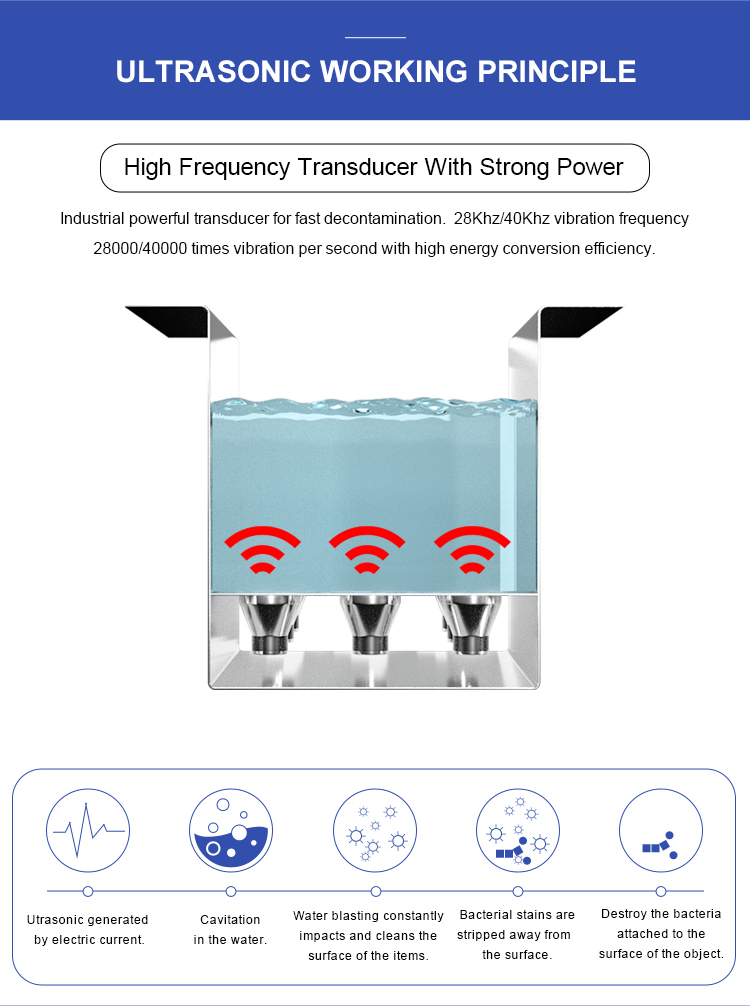

1). How Ultrasonic Cleaning Works: Ultrasonic cleaning involves the following key mechanisms:

Cavitation: As mentioned earlier, the high-frequency sound waves create tiny bubbles called cavitation bubbles in the cleaning solution. These bubbles form and collapse rapidly, releasing high-energy shockwaves that help dislodge contaminants from the object's surface.

Implosion: When the cavitation bubbles collapse, they create a

high-energy implosion. This implosion generates intense localized

pressure and temperature differentials, which produce a scrubbing

action, effectively cleaning the object.

2). Cleaning Solution: The cleaning solution used in ultrasonic cleaning can vary depending on the application and the type of contaminants to be removed. Water is commonly used as a base, and specific detergents or cleaning agents are added to enhance the cleaning process. These additives can include surfactants, solvents, rust inhibitors, degreasers, or specialized chemicals tailored for particular cleaning tasks.

3). Frequency and Power: Ultrasonic cleaners operate at various frequencies, typically ranging from 20 kHz to 400 kHz. The frequency selection depends on factors such as the size of the contaminants, the material being cleaned, and the desired cleaning intensity. Higher frequencies are generally used for delicate items or fine cleaning, while lower frequencies are suitable for heavy-duty cleaning tasks. The power of the ultrasonic cleaner is also adjustable to control the intensity of the cleaning process.

4). Cleaning Applications: Ultrasonic cleaning is employed in a wide range of industries and applications. Some common examples include:

Jewelry and Watchmaking: Ultrasonic cleaners are effective at removing dirt, oils, and polishing compounds from intricate jewelry pieces, gemstones, and watches.

Electronics: Electronic components, circuit boards, and delicate

parts can be cleaned without causing damage or disrupting the

functionality of the devices.

Automotive: Ultrasonic cleaning is used to clean engine parts,

carburetors, fuel injectors, and other automotive components.

Medical and Dental: Medical instruments, surgical tools, dental

equipment, and prosthetics can be thoroughly cleaned using

ultrasonic technology.

Optics: Lenses, eyeglasses, camera equipment, and other optical

devices benefit from ultrasonic cleaning to remove smudges, oils,

and contaminants.

5). Considerations and Limitations: While ultrasonic cleaning is highly effective, there are some considerations and limitations to keep in mind:

Material Compatibility: Certain materials may be sensitive to ultrasonic cleaning, such as soft plastics, porous materials, or items with loose components. It's important to ensure that the object being cleaned is compatible with the ultrasonic process.

Size and Shape: The size and shape of the objects being cleaned

should be taken into account when selecting an appropriate

ultrasonic cleaner. Objects should fit comfortably within the

cleaning tank without overcrowding, allowing the sound waves to

reach all surfaces.

Precautions: Safety precautions should be followed, including the

use of appropriate personal protective equipment (PPE) and ensuring

proper ventilation when working with cleaning agents.

Post-Cleaning: After ultrasonic cleaning, it may be necessary to

rinse the objects with clean water and dry them thoroughly to

remove any remaining cleaning solution or moisture.

Overall, ultrasonic cleaning is a versatile and efficient method for removing contaminants from a wide range of objects and materials, offering improved cleaning results and productivity compared to traditional cleaning methods.

2. Product Features:

1). Working process: the 1st tank ultrasonic cleaning with heating,

remove the rust, grease and dust from the cleaning items. The 2nd

tank high pressure spraying to provide deep cleaning service. The

alarm buzzes once complete the spraying process.

2). The inner tank material: the use of 304 stainless steel,

thickened to 2mm, manual argon welding, strong and durable;

3). Adjustable time: 1-99 minutes/hour adjustable, can be opened

often;

4). Memory function: the device has an independent memory chip, and

there is no need to reset over and over after the time is set;

5). Equipment power cord: the use of industrial thickened power

cord, safe and durable;

6). Industrial grade transducer: the use of industrial shock head,

strong force and good effect, can work 24 hours uninterrupted;

7). Generator control system: independent generator control system,

flexible control, can be set according to the user's cleaning needs

to adjust the ultrasonic power;

8). Heating automatic constant temperature system: 20-95 degrees

adjustable, equipped with stainless steel heating tube, fast

heating speed.

3. Double Tanks Industrial Ultrasonic Cleaner CHS Series:

Ultrasonic Cleaning, Heating, High Pressure Spraying

4. What are some common cleaning agents or chemicals used in ultrasonic cleaning?

In ultrasonic cleaning, various cleaning agents or chemicals can be used to enhance the cleaning process and improve the removal of specific types of contaminants. The choice of cleaning agent depends on the nature of the contaminants, the material being cleaned, and the desired cleaning outcome. Here are some common cleaning agents used in ultrasonic cleaning:

Detergents: Detergents are a common choice for general-purpose cleaning in ultrasonic cleaning applications. They are formulated to remove dirt, oils, greases, and other common contaminants. Detergents can be water-based or solvent-based, and their composition may include surfactants, emulsifiers, and other ingredients that aid in the removal of specific types of dirt or contaminants.

Solvents: Solvents are used when there are specific types of contaminants that are difficult to remove with detergents alone. Solvents help dissolve or break down oils, waxes, adhesives, and other stubborn substances. Examples of solvents commonly used in ultrasonic cleaning include isopropyl alcohol, acetone, and mineral spirits. It's important to choose solvents that are compatible with the material being cleaned.

Rust Inhibitors: Rust inhibitors are additives that can be used in the cleaning solution to prevent or inhibit the formation of rust on metal surfaces. They provide a protective barrier against oxidation, helping to maintain the integrity and appearance of the metal. Rust inhibitors are particularly useful when cleaning ferrous metals that are prone to rusting.

Degreasers: Degreasers are specialized cleaning agents designed to remove heavy grease and oil deposits. They are commonly used in automotive and industrial cleaning applications. Degreasers help to break down and emulsify grease, facilitating its removal from parts and surfaces.

Acidic or Alkaline Cleaners: Acidic or alkaline cleaners are used for specific cleaning tasks that require a more aggressive approach. Acidic cleaners are effective in removing scale, mineral deposits, and rust from certain metals. Alkaline cleaners are suitable for removing heavy grease, oils, and organic residues. These types of cleaning agents should be used with caution, as they can be corrosive and potentially harmful to certain materials.

Enzymatic Cleaners: Enzymatic cleaners are bio-based cleaning agents that utilize enzymes to break down organic contaminants such as proteins, blood, and biological residues. They are commonly used in medical and laboratory settings and are effective at removing stubborn organic stains.

When selecting a cleaning agent for ultrasonic cleaning, it is essential to consider factors such as material compatibility, the type of contaminants to be removed, and any specific cleaning requirements or regulations relevant to your industry or application. It's recommended to follow the manufacturer's instructions and guidelines for the appropriate concentration and usage of the cleaning agents to ensure effective and safe cleaning results.

5. Customer's Cleaning Feedback:

6. FAQ:

1). Are you a factory or trading company?

Blue Whale: We are a leading factory in ultrasonic cleaning field in China for 20 years. We have our own factory building including several floors of production sites and offices.

2). Do the products have CE/ROHS certificate?

Blue Whale: all of our products are under CE, FCC, KC regulations and compliance to ROHS, REACH.

3). What frequency is better for my parts?

Frequency is suggested based on pollutants in the objects. 28kHz frequency is stronger, better for car/motor/truck/vessel parts(oils, grease,rust,pastes, etc. ); 40kHz is better for PCB boards, electronic parts, etc. Higher precision goods, higher frequency.

4). Why should we use cleaning solution even though we have the ultrasonic cleaner?

Blue Whale: proper cleaning solution can help us to get the best cleaning effect. Like washing machine, when we use it to wash clothes, washing powder is needed to have the best effect.

5). Can we do ODM or OEM with you?

Blue Whale: we welcome customers to do ODM, OEM and wholesale. A brand authorization letter from your side is needed for ODM and OEM orders.

6). What’s the production lead time?

Blue Whale: for bench-top cleaners, usually we have some pieces in stock, we could ship out in 3 days if the quantity is less than 10pcs. If the qty is bigger, welcome to consult us. For industrial ultrasonic cleaners, it takes about 5-7 working days to produce.

7). What's the payment method and terms?

Blue Whale: for sample orders, 100% advance payment is required. For bulk orders, 50% / 80% deposit before production, the balance before shipment. We accept T/T and Western Union. The payment terms EXW, FOB, CIF, DAP and DDP are offered.

8). How about after sales services?

Blue Whale: one year warranty for all ultrasonic cleaners. If any technical problem during warranty time, replacement parts will be sent free. Technical support and customer service is also available lifelong.