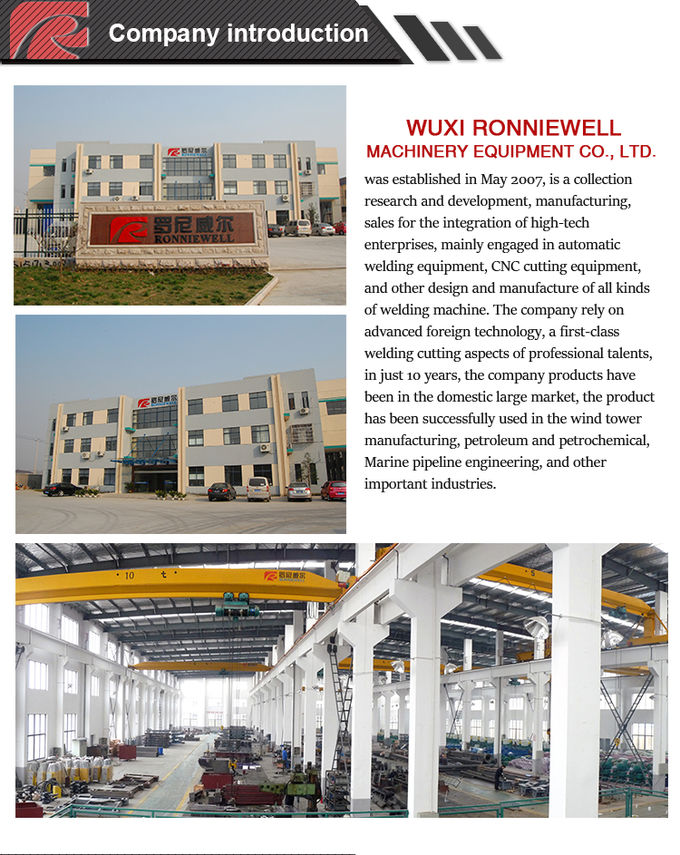

WUXI RONNIEWELL MACHINERY EQUIPMENT CO.,LTD |

|

Verified Suppliers

|

|

Tubular Section Traversing 5m Cantilever Welding Platform SAW Welding Manipulator

Brief introduction:

Feature:

Technical parameter list:

| Model | XLH-50 |

| Structure: | Motorized mobile on the rail |

| Platform vertical stroke | 5000mm |

| Platform work load limit | 300kg |

Lifting speed | 1000mm/min |

Trolley travel speed | 3500mm/min |

Rail inner gauge | G-G2000MM |

SAW welding power source | LINCOLN/Chinese/As per customer preference |

| Power supply | Fit for local standard |

Description

What Ronniewell can do for Ronniewell customers:

Points you may concern:

Customization - Can your machine or other products be customized?

Ronniewell: Sure. As a professional manufacturer, we have our own

engineer team, who is good at design, develop & build special

solution catering for your individual requirement.

Transportation-What about the transportation?

Ronniewell: Seaway is the most common transportation way for

oversea trading. Depends on your location, combined transport by

rail and sea is also an option. Certainly railway transportation is

also acceptable if it is the most suitable approach.

After sale service - What about the after-sale service?

Ronniewell: We provide 12month guaranty period for the whole

machine quality. During this time, any issue proved because of the

machine flaw itself,we would take the whole responsibility of it.

Except of the guaranty period,technical advisory support is

available freely covering the whole using life of the machine.

Engineer service on user premises is also available for necessary.

Video link

https://www.youtube.com/c/RonniewellAutomatedWeldingSolutionProvider

Welcome to follow us on following social media:

Facebook: https://www.facebook.com/weldingrotatorcn

LinkedIn: https://www.linkedin.com/in/automatedwelding