Shanghai Genius Industrial Co., Ltd |

|

Verified Suppliers

|

|

Arc welding robot safety requirements

One of the great benefits of welding robots is the ability to

replace people in hazardous or hazardous environments and avoid

injury. When the welding robot is working, no one can enter the

area where its motion safety is located, and take corresponding

reliable countermeasures.

For example, install a safety fence on the welding robot and its

peripheral equipment to prevent accidental injury from entering a

dangerous area; or install a plug - in electric contact switch on

the safety door at the entrance of the safety guardrail. Once the

safety door is opened, the robot controller will cut off the robot

driving power and the robot stops moving immediately.

It can also install multiple emergency stop switches in the nearest

place to the welding robot. Once an emergency or dangerous

situation occurs, the staff can press the emergency stop to stop

the robot.

In addition, it is best to integrate the safety circuit with the production line safety circuit, and it can be used in the event of an emergency.

Arc welding robot body specification

| Robot model | ZK1400 - 06 | |

| Application | Arc welding | |

| Mounting | Vertical ground installation | |

| Number of axes | 6 | |

| Payload | 6kg | |

| Max working radius | 1400mm | |

| Repeated posiontioning accuracy | 0.03mm | |

| Maximum joint range | J1 | RV reducer ±160° |

| J2 | RV reducer +110°, -70° | |

| J3 | RV reducer +65°, -120° | |

| J4 | RV reducer ±150° | |

| J5 | Hollow harmonic reducer +105°, -110° | |

| J6 | Hollow harmonic reducer ±320° | |

| Maximum joint speed | J1 | RV reducer 201.9°/S |

| J2 | RV reducer 198.3°/S | |

| J3 | RV reducer 198.3°/S | |

| J4 | RV reducer 296.2°/S | |

| J5 | Hollow harmonic reducer 197.5°/S | |

| J6 | Hollow harmonic reducer 247.2°/S | |

| Allowable bending moment N.m | J4 | RV reducer 9.8N.m |

| J5 | RV reducer 9.8N.m | |

| J6 | Hollow harmonic reducer 4N.m | |

| Allowable inertia Kg.㎡ | J4 | RV reducer 0.3kg.㎡ |

| J5 | RV reducer 0.3kg.㎡ | |

| J6 | Hollow harmonic reducer 0.05kg.㎡ | |

| Body total weight | KG | 185KG |

| Operating environment | Temperature | 0℃ - 45℃ |

| Humidity | 20% - 80% | |

| Others | Keep away from corrosive gases or liquids or explosive gases, | |

| Power capacity | 6KVA (Robot) + 24KVA (Welding source | |

Control system introduction

Integrated drive and control, open control system, comprehensive

compatibility.

1. Adapt to a variety of welding power

2. Restarting a weld / arc reignition

3. Arc breaking restart

4. Scratch start

5. Sticky wire detection

6. (2D 3D 4D seek) Starting point search

7. Multistation reservation.

8. Swing arc ( Positive arc, Triangular arc, circular arc ) .

FAQ

Q: Are you a manufacturer or a trading company?

A: We are a manufacturer, and our factory located in Nantong city,

Jiangsu province. Our company occupies an area of 32,000 square

meters, with a plant area of 25,000 square meters. It has 72 senior

technicians, 42 technicians directly researching and developing, we

are a manufacturer with strong R&D capabilities and own core

technology, sincerely welcome to visit our factory.

Q: How about your after - sale service?

A:

1. Installation Services: In the period of installation and

debugging, we shall offer training about effective operation and

maintenance.

2. Technical Services: We can assist our clients to solve all kind of technical problems with our capable technical team, and we own adequate experience for production line transformation project.

3. Warranty Services: We offer free after sale service except the

engineers' traveling expense for any quality problem occurs during

our 12 months warranty period.

.

Q: What is your payment term?

A: The payment method is 50% prepayment, 50% balance before cargo

delivery if the client does not need onsite installation or

debugging;

The payment method is 50% prepayment, 40% balance before cargo

delivery, 10% upon verification in the client’s factory if the

client needs onsite installation or debugging.

Q: Can you provide customized service for our product?

A: Yes. We will provide you the professional robotic welding system

solutions according to your specific product. Only you need to send

us your detailed product drawings and welding requirement, then we

will come out with the customized technical proposal for you.

Q: What does the whole welding robot system include?

A: The whole welding robot system includes the robot arm, controller,

welding power source, positioners (one - axis or two axis),

fixtures, welding gun cleaner, safety fence, etc.

Q: What's the warranty period and delivery time?

A: Warranty period is 12 months. While the delivery time would be

within 15 - 30 days after receiving your deposit.

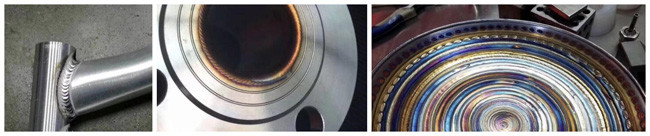

Welding effect

1. The surface has no rust, no high height, the welding is full and

the interface is firm.

2. The welding is consistent and does not need to be polished or

reduced by two-thirds.

3. There are no pores, cracks, unfused, slag inclusions, welds,

flying rafts, crater cracks, etc. on the surface.

Package