Shanghai Genius Industrial Co., Ltd |

|

Verified Suppliers

|

|

MAG welding robot description

Metal active gas welding, also known as MAG welding, is the most common welding method in the United States, Europe, and Japan. The high productivity offered by MAG welding robots have contributed to its popularity.

The principle of metal active gas welding is that a metallic wire is fed through the welding gun and melted in an arc. The wire serves the dual purpose of acting as the current - carrying electrode and the weld metal filler wire. Electrical energy is supplied by a welding power source.

A shielding gas that flows through the gas nozzle protects the arc and the pool of molten material. The shielding gas is either inert (MIG welding) or active (MAG welding). In this context, an inert gas is one that does not react with the molten material. Examples of gases in this category are argon and helium. Active gases, on the other hand, participate in the process between the arc and the molten material. Argon containing a small proportion of carbon dioxide or oxygen is an example of an active gas.

MAG welding requires the use of an active gas (i.e. carbon dioxide and oxygen). CO2 is a more commonly used shortening of MAG welding gas.

Metal active gas welding is the most commonly used arc-welding technique for sheet metal welding, mainly of steel. The wire electrode serves both as filler material and as arc electrode. The molten material is protected from oxygen by chemical reactions between an active gas, like CO2, and additives in the wire electrode. Typical applications for MAG welding include bicycle frames construction and automobile repair.

MAG welding robots are the perfect contender for welding processes where the quality and speed of the repetitive weld are crucial. It's a great way to improve efficiency and consistency while quickly receiving a Return On Your Investment.

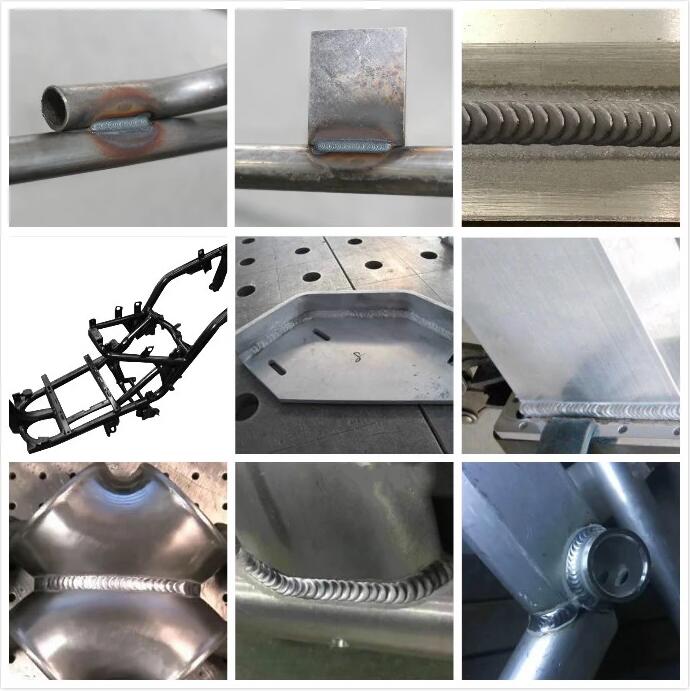

MAG welding robot application

Typical applications for MAG welding include bicycle frames

construction and automobile repair.

Robot body specification

| Robot model | ZK1400-06 | |

| Application | Arc welding | |

| Mounting | Vertical ground installation | |

| Number of axes | 6 | |

| Payload | 6kg | |

| Max working radius | 1400mm | |

| Repeated posiontioning accuracy | 0.03mm | |

| Maximum joint range | J1 | RV reducer ±160° |

| J2 | RV reducer +110°, -70° | |

| J3 | RV reducer +65°, -120° | |

| J4 | RV reducer ±150° | |

| J5 | Hollow harmonic reducer +105°, -110° | |

| J6 | Hollow harmonic reducer ±320° | |

| Maximum joint speed | J1 | RV reducer 201.9°/S |

| J2 | RV reducer 198.3°/S | |

| J3 | RV reducer 198.3°/S | |

| J4 | RV reducer 296.2°/S | |

| J5 | Hollow harmonic reducer 197.5°/S | |

| J6 | Hollow harmonic reducer 247.2°/S | |

| Allowable bending moment N.m | J4 | RV reducer 9.8N.m |

| J5 | RV reducer 9.8N.m | |

| J6 | Hollow harmonic reducer 4N.m | |

| Allowable inertia Kg.㎡ | J4 | RV reducer 0.3kg.㎡ |

| J5 | RV reducer 0.3kg.㎡ | |

| J6 | Hollow harmonic reducer 0.05kg.㎡ | |

| Body total weight | KG | 185KG |

| Operating environment | Temperature | 0℃ - 45℃ |

| Humidity | 20% - 80% | |

| Others | Keep away from corrosive gases or liquids or explosive gases, | |

| Power capacity | 6KVA (Robot) + 24KVA (Welding source) | |

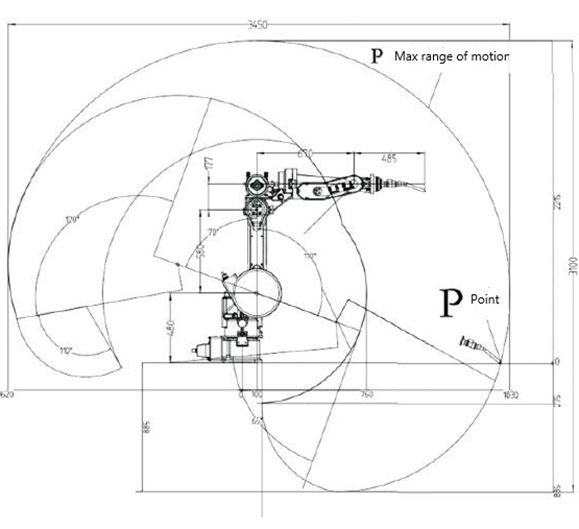

Robot motion range

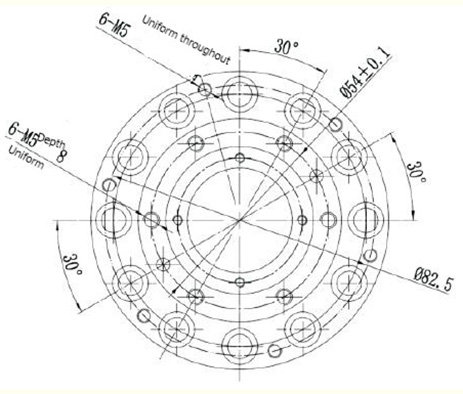

Installation dimensions of welding torch flange

Installation size of robot base

Welding torch clearing device

Welding effect