Shanghai Genius Industrial Co., Ltd |

|

Verified Suppliers

|

|

The shaft welding robot workstation is a special equipment specially developed for the shaft welding in the universal circuit breaker in the low - voltage electrical industry. A special rotary - axis welding robot workstation has been introduced.

The shaft welding robot workstation consists of an arc welding

robot, a welding power source, a welding gun wire feeding

mechanism, a rotary double station positioner, a fixture and a

control system. The workstation is used for the welding of various

types of workpieces with the rotating shaft as the base body (with

several cantilever arms on the top), and various types of shaft

automatic welding can be realized by using different clamps in the

same workstation. The welding is now highly accurate in position.

Due to the use of the double - position positioner, the other parts

can be disassembled and assembled while welding, which greatly

improves the efficiency.

Technical indicators: shaft diameter: Ф10-50mm, length 300-900mm,

welding speed 3-5mm/s, welding process using MAG mixed gas

protection welding, positioner rotation, displacement accuracy of

0.05mm.

It is widely used in high - quality, high - precision welding of

various types of workpieces for rotating shafts, and is suitable

for electric power, electrical, mechanical, automotive and other

industries. If manual arc welding is used for shaft welding, the

labor intensity of the workers is extremely high, the consistency

of the products is poor, and the production efficiency is low, only

2-3 pieces/hour. With the automatic welding station, the output can

reach 15-20 pieces / hour, and the welding quality and product

consistency are also greatly improved.

MIG welding manipulator body specification

| Robot model | GNS1400W - 06 | |

| Application | Arc welding | |

| Mounting | Vertical ground, lifting, hanging | |

| Number of axes | 6 | |

| Max payload | 10 kg | |

| Max working radius | 1400mm | |

| Repeated posiontioning accuracy | 0.07mm | |

| Body total weight | KG | 185KG |

| Operating environment | Temperature | 0℃ - 45℃ |

| Humidity | 20% - 80% | |

| Others | Keep away from corrosive gases or liquids or explosive gases, Keep away from water, oil, dust Keep away from source, magnetic field, high frequency signal source | |

| Power capacity | 6KVA (Robot) + 24KVA (Welding source) | |

| Performance | Motion range | Max speed | Load capacity |

| J1 | ±160° | 176.7 °/s | 511Nm |

| J2 | -72° ~ +110° | 173.6 °/s | 416Nm |

| J3 | -120 ° ~ +70° | 170.0 °/s | 188Nm |

| J4 | ±150° | 295.9 °/s | 1Nm |

| J5 | -110 ° ~ +105° | 197.3 °/s | 44Nm 0.30kg.㎡ |

| J6 | ±320° | 194.6 °/s | 68Nm 0.05kg.㎡ |

MIG welding manipulator excellent performance

Precision

Unit:mm

| Type | Actual data (Genius) | Reference data (Import) | Test speed | Test scheme |

| Position repeatability RP | 0.063 | ± 0.07 | 60m/min | A |

| Tracking accuracy ATp | 0.322 | 0.500 | 3m/min | B |

| Track repeatability RTP | 0.060 | -- | 2m/min | A |

| Track speed accuracy | 0.034% | -- | 2m/min | A |

| Track speed repeatability RV | 0.025% | -- | 2m/min | A |

| Position overshoot | 0.052 | 0.050 | 2m/min | A |

| Big circle roundness1 | 0.617 | -- | 2m/min | A |

| Big circle roundness2 | 0.402 | -- | 2m/min | B |

| Small circle roundness | 0.286 | 0.300 | 2m/min | A |

Noise

Unit:dB

| Motion position | The 1st axis | The 2nd axis | The 3rd axis | The 4th axis | The 5th axis | The 6th axis | 6 axises linkage |

| Measured value | 65.6-70 | 61.8-66.8 | 58.4-66.3 | 62.7-67.7 | 61.2-69.1 | 58.4-62.4 | 62.4-68.3 |

★ Noted

1. The speed was 100%, the ambient noise was 54.3dB, and the

ambient temperature was 15.9°C.

2. Using the pulse sound level meter (HS5660B), the measured value

is measured from the distance of 1 m from the measured position.

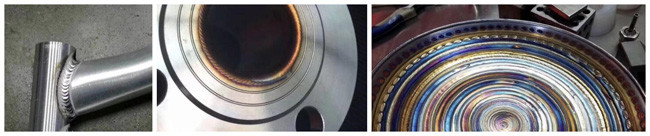

Welding effect

1. The surface has no rust, no high height, the welding is full and

the interface is firm.

2. The welding is consistent and does not need to be polished or

reduced by two-thirds.

3. There are no pores, cracks, unfused, slag inclusions, welds,

flying rafts, crater cracks, etc. on the surface.