CHANGSHA SUPMETER TECHNOLOGICAL CO.,LID |

|

Dynamic Weight Indicator/Scales, Installed On Komatsu Wa450 Wheel Loader

Display

1. 640×480 TFT color display screen for English character display.

2. Weight Display Range of Indicator: -99,999~99,999.

3. System Weighing Range: 100~12,000kg.

4. Scale Division: Optional 1, 2, 5, 10, 20, 50kg.

5. Display Refreshing Time: Setting Range 0.1~2.0s.

6. Using two oil pressure sensors for higher weighing accuracy than using one.

7. 24-bit ∑-△ADC with internal resolution 1/1,000,000 and sampling frequency 400Hz.

System Configuration

1 Weighing Indicator with Thermal Printer.

1 Position Sensor.

2 Oil Pressure Sensors.

2 Plate Type Three-way Joints.

1 Mounting Fitting.

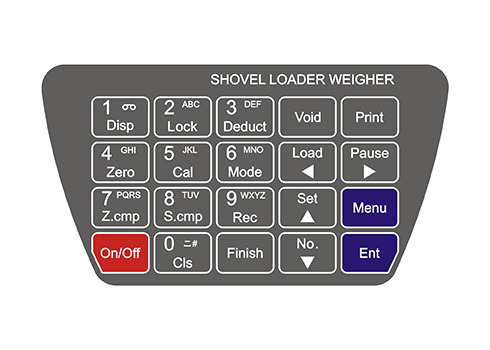

Keypad

1. 20-key English keypad with controllable backlight.

2. Menu&Shortcut mode operation with key tone.

3. Number and English Alphabet can be inputted

Operation in Loading Process

| Key Name | Description |

| 【Load】 | Enter Loading state with blue sign ‘▲’ displaying. Let the bucket of wheel loader stay at the lowest position before pressing【Load】. |

| 【Finish】 | Truck Mode: Save the current Loading Record and Clear Screen after the truck-loading process finished. |

| Mix Mode: Save the Loading Record of the current Material No. and Clear Screen. | |

| 【No.】 | Truck Mode: it’s for inputting Truck No.. |

Mix Mode: It’s for changing Material No.. After the new Material No. inputted, the current Material No.’s Loading Record will be saved automatically, and then the new Material No.’s historical Loading Record will be displayed again for material-reloading operation. | |

| Axle Type Mode: It’s for inputting Truck Axle Number and Truck Tare Weight. | |

| 【Pause】 | Enter Pause state with red sign ‘■’ displaying. |

| 【Void】 | Cancel Totalizing: If the present Single-bucket-loading-weight is not accurate, press the key to deduct it from Totalized Loading Weight. |

| 【Print】 | Print Loading Records. |

| 1/【Disp】 | Display Interface Switch. |

| 2/【Lock】 |

|

| 3/【Deduct】 | Do【Deduct】operation if the present Single-bucket-loading-weight is excessive. After entering the working state of 【Deduct】, the present Single-bucket-loading-weight will be deducted from Totalized Loading Weight, and the realtime weight of the materials in the bucket will be tracked and displayed in the display area [14]. After the materials in the bucket reduced according to the actual need, press the key 【Ent】 to totalize the weight of the remaining materials in the bucket to Totalized Loading Weight. |

| 9/【Rec】 | F3 Record Management [Query/Clear/USB Copy]. |

| 0/【Cls】 | Clear Screen without Saving Present Loading Record. |

| 【Ent】 | Backlight Switch of Keypad. Auto-on time of keypad backlight: 17:00~8:00. Auto-off time of keypad backlight: 8:00~17:00. |

| Check if the U-disk is ready. | |

| 【On/Off】 |

|

Menu Operation

| Key Name | Description |

| 【Menu】 | Enter Main Menu / Exit. |

| 【Ent】 | Enter / Save. |

| 【◄】 | Cursor shifts left. Backspace. |

| 【►】 | Cursor shifts right. |

| 【▲】 | Cursor shifts up. Display the previous option. |

| 【▼】 | Cursor shifts down. Display the next option. |

Parameter Setting Operation

| Key Name | Description |

| 【Set】 | Setpoint Parameters Setting. |

| 【0~9】 | Number Input. |

| 【A-Z】 | English Alphabet Input. |

| 【Print】/【IME】 | Input Method Switch: Number / English / Chinese PinYin. |

Oil Pressure Sensor Interface

1. Excitation Voltage/Max.Current: DC12V/100mA & DC5V/100mA.

2. 2 Oil Pressure signal inputs.

3. Signal Input Range: Optional 0~20mV, 0~5V[Factory Set Value].

4. ∑-△ADC: 24-bit, 1,000,000 internal code used.

5. Sampling Frequency: 400Hz.

Position Sensor Input Interface

2 Switch signal Input.

Output Voltage: DC12V.

Max. Output Current: 100mA.

Package size:

Delivery