CHANGSHA SUPMETER TECHNOLOGICAL CO.,LID |

|

Touch Screen Weight Scales Indicator, Supmeter Organic Fertilizer Packaging Machine Controller

Main Features:

² Suitable for Ration Packing Scale with optional Hopper-weighing Mode, Bag-weighing Mode and Loss-in-weight Mode.

² EMC design with high anti-jamming capability, suitable for industrial environment.

² Cortex-A8 CPU with 600MHz Clock, 128M RAM and 128M Flash.

² 7”/10.2” Ultralight and ultrathin TFT touch screen with embedded weighing/control module.

² Loadcell Interface

l Max. Connection Quantity: 16 Loadcells (350Ω).

l 2 Definable analog signal AOs[0~10V] for weight signal output or ‘High/Medium/Low Speed Feed’ control.

² Digital Communication Interface

l COM1[RS232]&COM2[RS485] for connecting Host IPC/PLC and LED Remote Display.

l COM[RS232] for connecting RS232 Serial Printer.

l USB1 for connecting USB mouse, downloading HMI software from U-disk and copying data to U-disk.

User Login Interface

| Name | Operation | Note |

| 【Login】 | User Login. Exfactory Passwords:

| Operation ‘Main Menu / F5 User / Password / PSW Set’ for Modifying Password. |

| 【User Name】 | After password inputted, the matching User Name will be displayed. |

|

| 【Operate】 | Enter ‘Main User Interface’. | Operation ‘Main Menu / F5 User / Password / Login [Logoff]’ for Re-login and Logoff. |

Button Operation

| Name | Operation | State Indicator | Authorization |

| 【Auto】 | Auto / Manual [Emergency Stop] switch. | Green: Auto state. Grey: Manual state. | All Users |

| 【Start】 | Start. | Green: Running state. Grey: Stop state. | |

| 【Re-run】 | Clear Alarm & Recover Running. | ||

| 【Stop】 | Normal Stop [Last Batch]. Stop after the present batch finished. | Flashing Red. | |

| 【E-Stop】 | Emergency Stop. | ||

| 【Alarm】 | Alarm Query / Clear Alarm. ‘Auto/Pause’ state: Recover Running after alarms cleared. | Red: Alarm state. | |

| 【Print】 | Report Print:

| ||

| 【Lock】 | Screen-locking: Locking/unlocking the operating buttons of main user interface. Auto Screen-locking: Refer to parameter [901]. | Flashing Red: Locked. Grey: Unlocked. | |

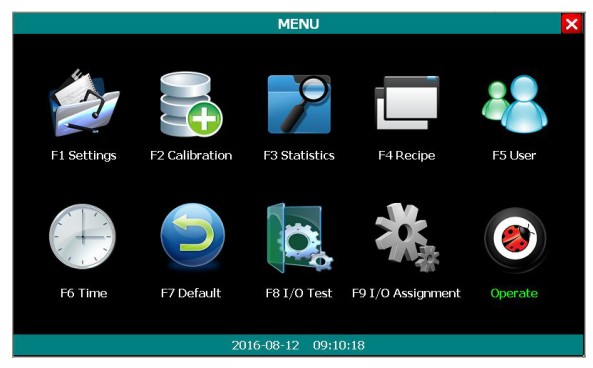

| 【Menu】 | Enter Main Menu. | ||

| 【User】 | User Login. Display: Operator / Engineer / Admin. | ||

| 【Zero】 | Manual Zero [No Power-down Protection]. | Flashing green. | |

| 【Bag】 | Bag-clamp/release Request. | Green: Bag-clamping state. Grey: Bag-releasing state. | |

| 【Bulk】 | Manual Start/Stop Bulk Feed. | Green: Working state. | |

| 【Med】 | Manual Start/Stop Medium Feed. | ||

| 【Drip】 | Manual Start/Stop Dribble Feed. | ||

| 【Dump】 | Manual Start/Stop Dumping. | ||

| 【Mat.】 | Manual Start/Stop Supplying Materials into Feeding Bin. | Flashing green. | |

| 【Clear】 | Clear Screen: Clear the display values of Feeding Weight, Totalized Weight, Batch Count and Cycle Speed. | Engineer Administrator |

Alarm Messages

| Message | Alarm Cause | Solution |

| Weight Upper Limit | Weight ≥ Upper Limit. | Refer to parameter [205] ‘Weight Upper Limit’. |

| Tolerance Alarm | Up Tolerance Alarm. Low Tolerance Alarm. | Refer to parameter [200] ‘Up Tolerance Limit’ and [201] ‘Low Tolerance Limit’. |

| Pause Alarm | For Tolerance Alarm. | Refer to parameter [310] ‘Pause for Tolerance Alarm’. It’s allowed to do ‘Manual Dribble Re-feed’ for Low Tolerance Alarm. Press DI button ‘Start / Clear Alarm’ to recover running. |

| For Dumping Gate Close Timeout. | After fault handling, press DI button ‘Start / Clear Alarm’ to recover running. | |

| For Dumping Gate Open Timeout. | ||

| For Auto-feed Timeout Alarm. | ||

| Auto-feed Timeout | Auto Feeding Time≥T10. | Refer to parameter [412] ‘T10 Auto-feed Timeout’. |

| Auto Dump /Bag-Release Timeout | Bucket Scale: Auto Dumping Time≥T11. | Refer to parameter [413] ‘T11 Auto Dump/ Bag-release Timeout’. |

Bag Scale: Auto Bag-Releasing Time≥T11. | ||

| Material-supply Timeout | Material Supplying Time≥T12. | Refer to parameter [414] ‘T12 Manual/Auto Material-supply Timeout’. |

| Dumping Gate Open Timeout | Refer to parameter [407] ‘T6 Dumping Gate Open Timeout’. Refer to ‘6.5 F9 I/O Assignment’. | Check if the set value of T6 is too small. Check if the installation position and signal connection of the position switch ‘Dumping Gate Opened in Place’ are correct and if the position switch is damaged. Check if the driving device of dumping gate is damaged. |

| Dumping Gate Close Timeout | Refer to parameter [409] ‘T8a Dumping Gate Close Timeout’. Refer to ‘6.5 F9 I/O Assignment’. | Check if the set value of T8a is too small. Check if the installation position and signal connection of the position switch ‘Dumping Gate Closed in Place’ are correct and if the position switch is damaged. Check if the driving device of dumping gate is damaged. |

Main Manual Interface

Delivery:

Touch Screen Weight Scales Indicator, Supmeter Organic Fertilizer Packaging Machine Controller