CHANGSHA SUPMETER TECHNOLOGICAL CO.,LID |

|

Digital Guide Rail Type Weight And Force Controller With High Speed Conversion And Sampling Frequency With Dc24v

Main Features:

1. Applications: Weight/Force Display, Peak Value Detection&Display Holding, Auto Weight-checking, Setpoint DO Output and AO/Digit Transmission.

2. EMC design with high anti-jamming capability, suitable for industrial environment.

3. 32-bit ARM CPU with 48MHz clock & high arithmetic speed.

4. 6+6 Red LED digital tubes for English character and digit display.

5. 4-key English keypad for Menu&Shortcut mode operation.

6. 24-bit High-precision and high-speed ∑-△A/D conversion module with 1/1,000,000 internal resolution and max. sampling frequency 3200Hz.

7. Max. Connection Quantity: 8 Loadcells (350Ω).

Keypad Operation

| Key Name | Function | Description |

| 【■】 | 【MENU】 | Enter Main Menu / Exit. |

| 【LOCK】* | Key-locking / Key-unlocking. | |

| 【►】 | 【►】 | Cursor shifts right. |

| 【ZERO】* | Manual Zero without Power-down Protection. | |

| 【▲】 | 【▲】 | Display the next interface or option. |

| 【SET】* | Setpoint Parameters Setting. | |

| 【8】 | 【ENT】 | Enter / Save / Clear Alarm. |

| 【CLS】* | Clear Screen [Clear the display value of Peak Hold Value and Weight-checking Value]. |

Alarm Signs

| Sign | Alarm Cause | Solution |

| Err1 | RAM Failure. | Replace the chip RAM. |

Err2.1 Err2.2 | EEPROM Failure. | Replace the chip EEPROM. |

| Err3 | Unused. | |

| Err4 | ADC Failure. | Replace the ADC module. |

| oV-Ad | Over ADC Range. | Weighing signal exceeds A/D conversion range. 1. Check if the loadcell is connected. 2. Check if the capacity of loadcell is too small. 3. Check if the loading weight is too big. |

| oL | Overload Alarm. | Gross Weight > (Scale Capacity + 9 × Scale Division). 1. Check if the loadcell is connected. 2. Check if the capacity of loadcell is too small. 3. Check if the loading weight is too big. |

| oV-nZ | Over ‘Manual/Auto Zero Limit’. | Refer to parameter [123] ‘Manual/Auto Zero Limit’. |

| tXX.XX | Preheating Time Countdown [min.sec]. | Refer to parameter [128] ‘Zero Upon Power Up’, [129] ‘Power Up Zero Time’ and [130] ‘Power Up Zero Limit’. Wait for the preheating time over or press any key to exit. |

| oV-Zr | Over ‘Power Up Zero Limit’. |

User Interface Diagram

Terminal

| No. | Pin | Description |

| POWER | DC12~24V Power Input Port | |

| 1 | DC- | DC Input -. |

| 2 | DC+ | DC Input +. |

| CAN [Optional] | CANBUS Digital Communication Port [COM3] | |

| 3 | L | Data -. |

| 4 | H | Data +. |

| RS485 | RS485 Digital Communication Port [COM2] | |

| 5 | B- | Data -. |

| 6 | A+ | Data +. |

| RS232 | RS232 Digital Communication Port [COM1] | |

| 7 | TXD | Transmit Data. |

| 8 | RXD | Receive Data. |

| 9 | GND | Signal Ground. |

| AO | Analog Output Port [Definable] | |

| 10 | Vo+ | 0~10V Voltage Signal Output] +. |

| 11 | mA+ | 0~20mA Current Signal Output +. |

| 12 | GND | VO/AO Output -. |

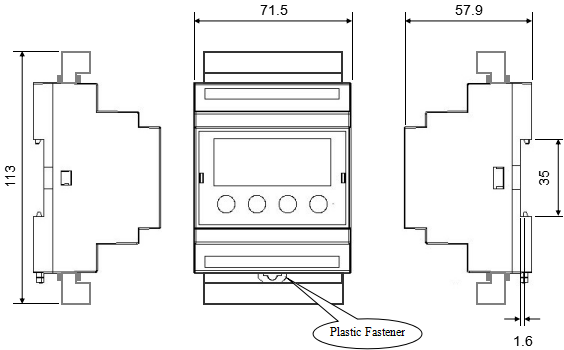

Installation

Delivery ways