Weighing Scale Controller Indicator With Loss - In - Weight For

Packing Machine

Main Features:

- BST106-B66[A] Suitable for Ration Packing Scale. Optional

Application Modes: 1-Bucket Scale, 2-Bucket Scale and 1-Bag Scale

with Auto Bag-releasing or Manual Bag-releasing.

- EMC design with high anti-jamming capability, suitable for

industrial environment.

- 32-bit ARM CPU with 48MHz clock & high arithmetic speed.

- 6+8 Red LED digital tubes for English character and digit display.

- English keypad for Menu&Shortcut mode operation with key tone.

- 24-bit High-precision and high-speed ∑-△A/D conversion module with

1/1,000,000 internal resolution and sampling frequency 400Hz.

- Special anti-vibration digital filtering algorithm for ensuring the

weighing stability and accuracy when there is strong vibration on

the load receptor, and the rapid response capability when the

weight signal changes.

- Max. Connection Quantity: 4 Loadcells (350Ω).

- Zero Upon Power Up, Zero Auto-tracking, Manual/Auto Zero and Zero

Calibration available.

- Load Calibration and Data Calibration available.

- Auto-locking, Key-locking, Key-unlocking, Digital

Setting&Calibration and I/O Testing functions available.

- 6 Normally open switch inputs [DI] and 8 normally open transistor

switch outputs [DO].

- Optional ‘Bulk/Medium/Dribble Feed’ DOs for feeding control.

Optional Continuous and Jogging Dribble Feed Methods.

- 1 Optional and definable analog signal AO[4~20mA] for weight signal

output or ‘Bulk/Medium /Dribble Feed’ control.

- Optional ‘Auto Correct Inflight’ function.

- Optional ‘Pause for Tolerance Alarm’ and ‘Auto Dribble Re-feed’

functions.

- Optional ‘Batch Target Control’ function [With Batch Count Target

or Batch Weight Target finished, the packing process will stop

automatically].

- 2 Communication ports [RS232&RS485] for connecting Host IPC/PLC

and LED Remote Display.

- With the multitasking mode, the weighing&control process will

not be interrupted by parameter setting and the other operations.

Technicals:

| Accuracy | Accuracy Grade | III |

| Verification Accuracy | 0.03% |

| Static Weighing Accuracy | 0.2%~0.5% |

| Packing Accuracy | 0.2%~0.5% |

| Display | 6+8 Red LED digital tubes for English character and digit display |

| Keypad | 4-key English keypad |

| Loadcell | Excitation Voltage/Max. Current | DC9V/120mA [4-350Ω loadcells] |

| Signal Input Range | 0~22.5mV |

| Output Sensitivity of Loadcell | 1.0~2.5mV/V |

| Non-linearity | 0.005%FS |

| Switch&Analog Signal Interface | DI | 6 Normally Open Switch Inputs [DI] |

| DO | 8 Normally Open Transistor Switch Outputs [DO]: DC24V, 250mA |

| AO | 1 Optional&Definable Analog Signal Output [AO]: 4~20mA |

| Digital Communication Interface | COM1 | RS232 |

| COM2 | RS485 |

| Connectable | Host IPC/PLC and LED Remote Display |

Model Panel-mounting User Interface

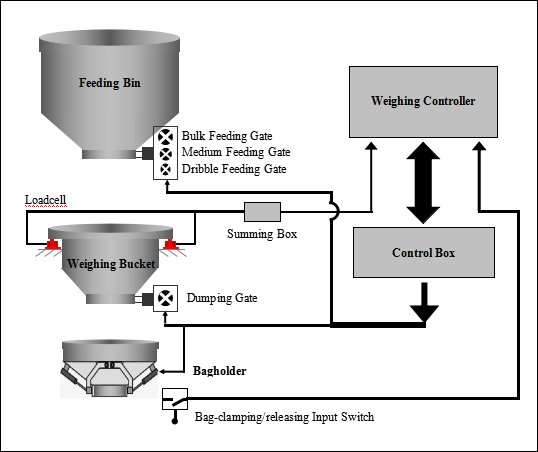

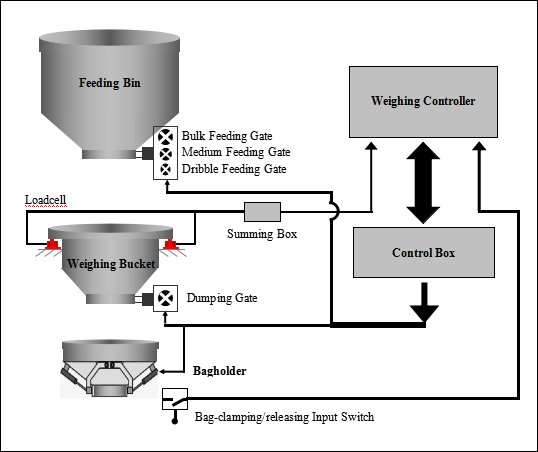

System Diagram for APP1.1 1-Bucket scale

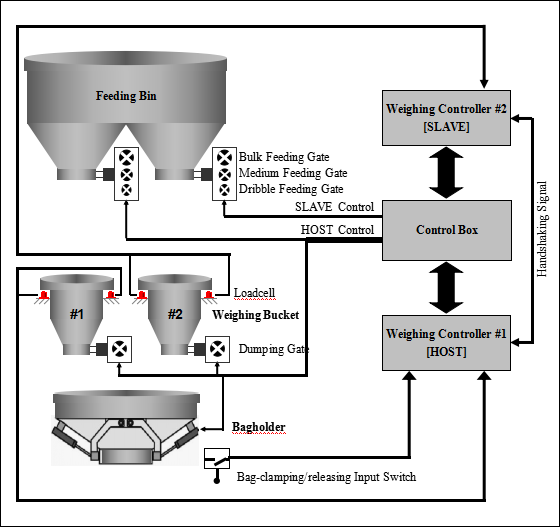

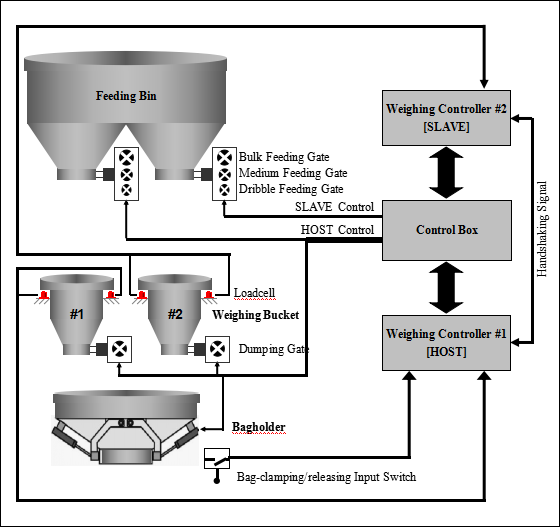

System Diagram for APP1.2 2-bucket scale

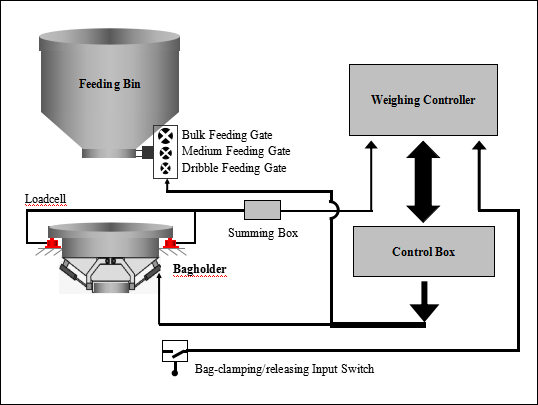

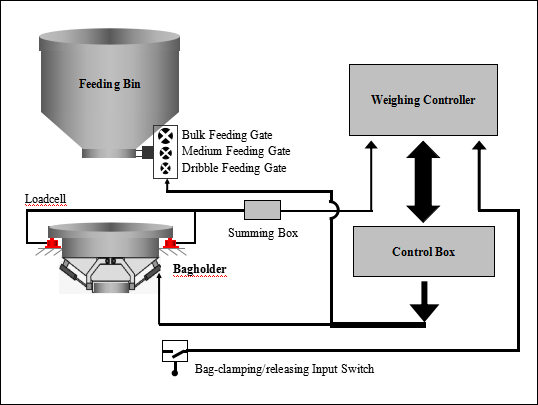

System Diagram for APP1.2 1-Bag Scale

Q: Are you trading company or manufacturer ?

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is

15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample. It is not free but with special

sample price.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us.