CHANGSHA SUPMETER TECHNOLOGICAL CO.,LID |

|

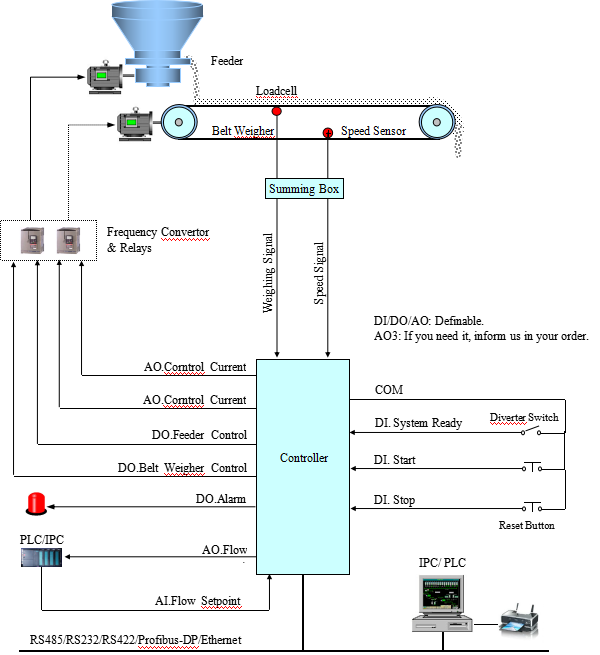

Zero Calibration And Auto Zero Tracking Belt Scale Weighfeeder Controller

Model Panel-mounting Terminal

The Numeric Display 1 displays Totalized Weight value and the Numeric Display 2-3 displays the following data:

| NO. | Display iterms | Sign | Range |

| 6 | Totalized Weight of Current Batch | P= | 0~999999 |

| 7 | AD Value | Ad= | 0~65535 |

| 8 | Zero Value | Zr= | 0~60000 |

| 9~11 | DI State | dI1-/dI2-/dI3- | -oFF/-on- |

| 12~15 | DO State | do1-/do2-/do3-/do4- | -oFF/-on- |

| 16 | AI Signal | AI1= | 4.00~20.00mA |

| 17~19 | AO Signal | Ao1=/Ao2=/Ao3= | 4.00~20.00mA |

| 20 | Totalized Weight High Speed Pulse | HP | 0~999999 Pulse |

| 21 | Totalized Weight Low Speed Pulse | LP | 0~999999 Pulse |

| 22 | Date | 20YY.MM.DD | Year. Month. Day |

| 23 | Time | HH.MM.SS-W | Hour. Minute. Second-Week |

| 24 | Totalized Weight of Current Shift | t= | 0~99999.9t |