CHANGSHA SUPMETER TECHNOLOGICAL CO.,LID |

|

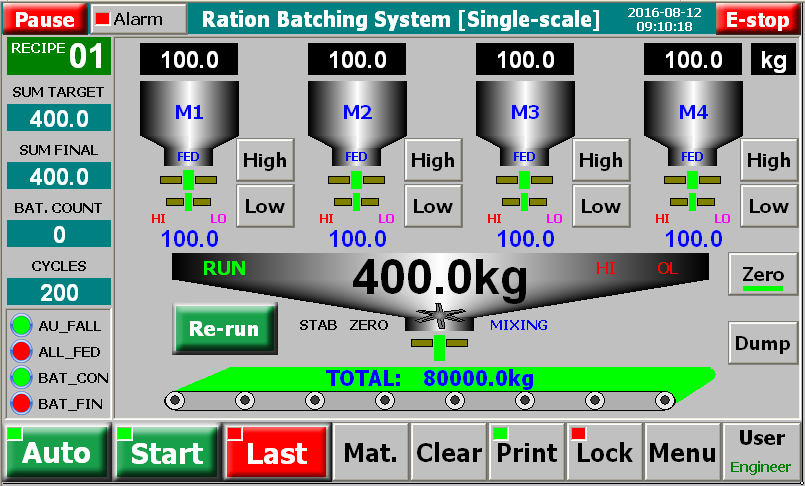

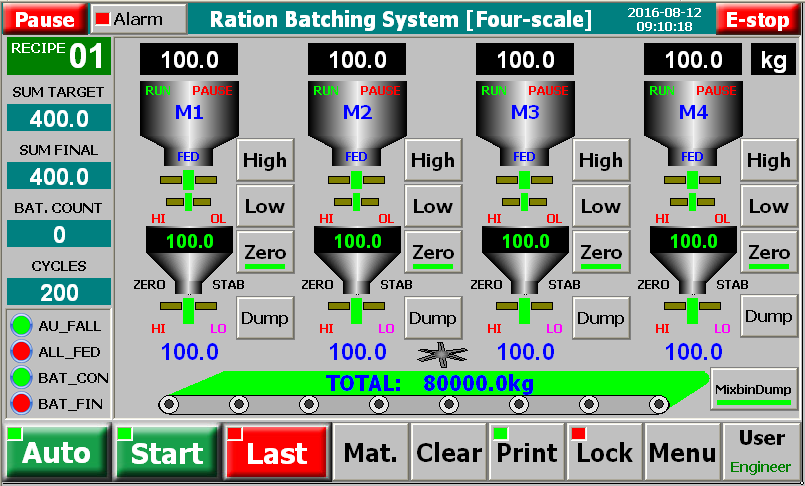

Four-Scale TFT-Touch Ration Batching Controller with 4-Material

Main Applications

Main Features

| Name | Description | Authorization |

| [NET] | Real-time Weight / Material Mn’s Feeding Weight [Weight Unit]. | |

| [GROSS] | Gross Weight. | |

| [HI] | Gross Weight Upper Limit Alarm. | |

| [OL] | Overload Alarm. | |

| [Cycles] | Batch Count. | |

| [▲]/HI | Up Tolerance Alarm. | |

| [▼]/LO | Low Tolerance Alarm. | |

| [Lack] | ‘Lack of Materials in Feeding Hopper’ Alarm. | |

| [Timeout] | ‘Material-supply Timeout’ Alarm. | |

| [Total] | Total Totalized Weight. | |

| [RUN] | Auto Running state. | |

| [PAUSE] | Pause state. | |

| [ZERO] | Gross Weight ≤ Non-load Zero Range. | |

| [STAB] | Weight is stable. | |

| [FED] | Material Mn Feeding Ended. | |

| [AU_FALL] | ‘Auto Correct Inflight’ Permission. | |

| [ALL_FED] | All Materials Feeding Ended. | |

| [BAT_CON] | ‘Batch Target Control’ is allowed. Refer to parameter [301] ‘Batch Target Control’ and [203] ‘Batch Count Target’. | |

| [BAT_FIN] | Batch Count Target Finished. | |

| [MIX] | The mixer is running. | |

| [BELT] | The mixing conveyor is running. | |

| [Recipe] | ‘Working Recipe No.’ Setting. | All Users |

| Recipe Parameters Setting. | Engineer | |

| [Mn Target] | Mn Target Weight. | |

| [Mn Final] | Mn Final Feeding Weight. | |

| [Sum Target] | The sum of the Target Weight of all the materials selected for batching. | |

| [Sum Final] | The sum of the Final Feeding Weight of all the materials selected for batching. | |

| [Cycles Target] | Batch Count Target. | |

| [Cycles Final] | Batch Count. | |

| [Time] | Date&Time. | |

| [Working Mode] | Refer to parameters [300]/[303]/[317]. | Administrator |