CHANGSHA SUPMETER TECHNOLOGICAL CO.,LID |

|

LED Display Batching Weighing Indicator Controller With 2-Speed Feeding Control By DOs Or AOs

Main Applications

Main Features

| CN1 [DI] | |||

| No. | Pin | Signal Name | Description |

| 1 | COM | COM | DI Common Terminal [DC-]. |

| 2 | DI1 | AUTO | Auto/Manual. ON: Auto state. OFF: Manual state / Emergency Stop. |

| 3 | DI2 | START | Start / Clear Alarm. In running process: Clear Alarm. Pause state: Clear Alarm & Recover Running. OFF→ON→OFF. |

| 4 | DI3 | PAUSE | Manual Pause. OFF→ON→OFF. |

| 5 | DI4 | DUMP_I | Manual Dump. 1. Stop state: ON: Manual Dump; OFF: Stop. 2. In the Auto-batching process If [312] ‘Dumping Mode’ = ‘0. HAnd’, it’s necessary to input the DI signal ‘Manual ‘Dump’ (OFF→ON→OFF) for triggering the dumping process. |

| 6 | DI5 | STOP | Normal Stop [Last Batch]. OFF→ON→OFF: The batching process will stop automatically after the present batch finished. |

| 7 | DI6 | SP3_I | Manual Dribble Re-feed. Valid at Pause state with Mn’s Low Tolerance Alarm. ON: Start Mn’s Dribble Feed. OFF: Stop Mn’s Dribble Feed. |

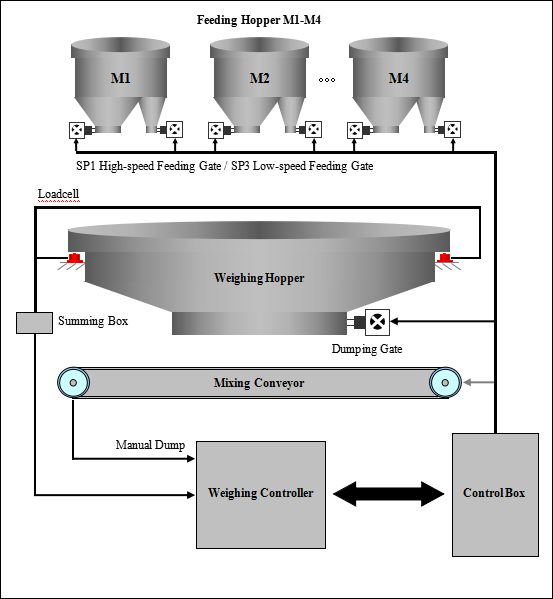

System Diagram for M1~M4 Ration Batching System

Application:

How long is the warranty period?

The warranty period for our products is 12 (twelve) months.

If the products from SUPMETER are proved to be unable to work normally due to unartificial reasons, and the problems can't be solved by customers under the technical support from SUPMETER, then customers can send the problematic items back to SUPMETER. SUPMETER is RESPONSIBLE to MEND (or REPLACE when necessary) them FREE OF CHARGE.

(Note: if after checking, the returned goods are proved to be in good condition, the trouble is resulted to be caused by improper operation by customers, SUPMETER is IRRESPONSIBLE to bear the shipping & other charges related to the returning.)