CHANGSHA SUPMETER TECHNOLOGICAL CO.,LID |

|

Mini 3-D/3-CH Force Measuring Controller Electronic Weighing Indicator For 1-3 Channels Force Measuring System

Pictures

| Name | Description | Range | Note |

| X | Channel X Real-time Force Value or Peak Value. | -5000~+5000 | Refer to Parameters [202]~[207]. |

| Y | Channel Y Real-time Force Value or Peak Value. | -5000~+5000 | |

| Z | Channel Z Real-time Force Value or Peak Value. | -5000~+5000 | |

| [F] | Real-time Resultant Force or Resultant Force Peak Value [Force Value Unit]. | 3-D Algorithm: F2 = X2 + Y2 + Z2 CUSUM Algorithm: F = X + Y + Z |

| Sign | Alarm Cause | Solution |

| AD_ER | ADC Failure. | Replace the ADC module. |

| OV_AD | Over ADC Range. | Force signal exceeds A/D conversion range. 1. Check if the loadcell is connected. 2. Check if the capacity of loadcell is too small. 3. Check if the loading force is too big. |

| OV_LD | Force Value Overload Alarm. | Force Value>(Single-channel Force Capacity+9×Scale Division). 1. Check if the loadcell is connected. 2. Check if the capacity of loadcell is too small. 3. Check if the loading force is too big. Refer to Parameter [102]. |

| Resultant Force Overload Alarm. | Resultant Force>(Max. Resultant Force+9×Scale Division). Refer to Parameter [102]. |

| LED light | Description |

| [RUN] | OFF: Real-time Force Value tracking display state. ON: Peak Value Detecting Result holding display state [Peak Value Detecting Process Finished]. Blinking: Peak Value tracking display state [In Peak Value Detecting Process]. |

| [AL1] | Real-time Resultant Force or Resultant Force Peak Value Upper Limit Alarm. Refer to Parameters [200]&[202]. |

| [AL2] | Real-time Resultant Force or Resultant Force Peak Value Lower Limit Alarm. Refer to Parameters [201]&[202]. |

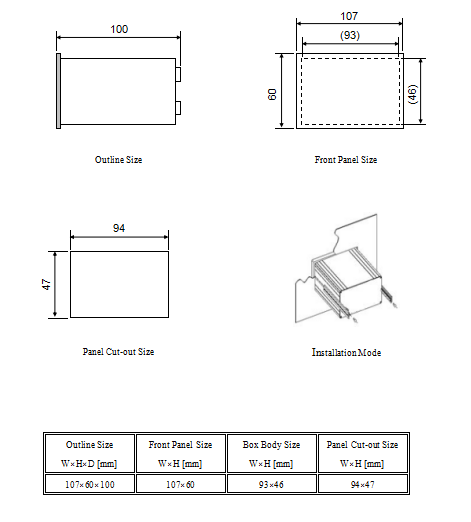

Installation