Duralium Belt Weigher Controller And Speed Sensor With Dust-Proof

For Conveyor Scale

Main Feature:

- EMC design with high anti-jam for industrial environment.

- 32-bit ARM CPU with 72MHz clock & high arithmetic speed.

- 128×64 LCD display screen with 7 background colors.

- 24-bit ∑-△ADC with internal resolution 1/1,000,000.

- High sampling frequency 400Hz.

- Special Anti-vibration Digital Filtering Algorithm for precise

weighing, stable display and rapid response.

- Zero Calibration & Auto Zero Tracking.

- Span Calibration & Segmenting Correction.

- Speed Calibration & Belt Length Calibration.

- The feeder and belt weigher can be controlled by DI&DO.

- Quick and steady PID ration feeding control.

- Queryable Records per shift/day/month of a year.

- Definable DI/DOAO/COM[Communication Port].

Technical Specification

- Power Supply: AC220V±15%, 50/60Hz, Max. 15W.

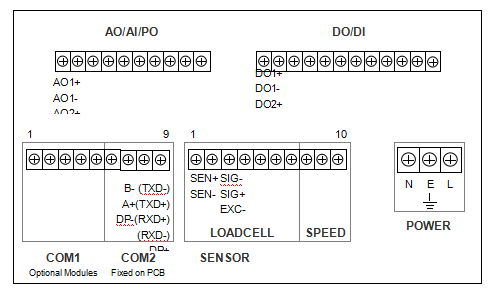

- Loadcell Excitation Voltage/Current: DC10V/250mA.

- 8 Loadcells[350Ω] connectable.

- Weighing Signal Input Range: 0~25mV.

- Speed Sensor Excitation Voltage/Current: DC12V/100mA.

- Speed Signal Input Range: 0.5~3000Hz.

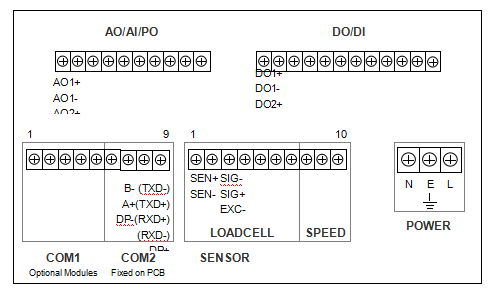

- 3 Normally Open Switch Inputs [DI].

- 4 Normally Open Relay Outputs [DO]: AC250V/DC24V, 1A.

- 1 ‘Totalized Weight’ Pulse Output [PO]: DC5~24V, 100mA.

- 2 ‘PID Control’ Analog Output [AO]: 4~20mA, 0.05%FS.

- 1 ‘Flow Set’ Analog Input [AI]: 4~20mA, 0.05%FS.

- COM1: Optional RS232/RS485/RS422/Profibus-DP/Ethernet.

- COM2: RS232.

- Connect Host IPC, Remote Display, Printer&Wireless Module.

- Outline Size [W×H×D]: 164 × 86 × 193 mm.

- Panel Cut-out Size [W×H]: 153 × 77 mm.

- Operating Temperature: -25℃~+45℃.

- Protection Level of Front Panel: IP65.

- Accuracy Grade: 0.5.

- Accuracy of Flow Control: 0.5%~1.0%.

Keypad Operation

If there is not any keypad operation in one

minute and it’s not in the processes of ‘F2 System Calibration’

& ‘F6 Factory Adjustment’, the controller will return to ‘Main

Display Interface’ automatically.

|

Menu Operation |

| Key Name | Description |

【MENU】 (【ESC】) | Enter Main Menu. Exit. |

| 【ENT】 | Enter/Save. |

| 【▲】 | Cursor shifts up or left. Display the previous interface or option. |

| 【▼】 | Cursor shifts down or right. Display the next interface or option. |

| 【0~9】 | Digit Input. |

|

Quick Operation |

| 【LOCK】 | - Key-locking.

- Key-unlocking.

|

| 【F1】 | Return to the initial display interface. |

| 【SET】 | Flow Set Value Setting. |

| 【ADJ-】 | Control Current -1mA. |

| 【ADJ+】 | Control Current +1mA. |

| 【AUTO】 | ‘Manual/Auto’ Control Mode Selection. |

| 【EXT】 | ‘Internal/External’ Flow Set Mode Selection. |

| 【ZERO】 | Zero Calibration. |

| 【CAL】 | Dynamic Span Calibration. |

| 【CLS】 | Clear Screen: Clear display value of Totalized Weight. |

| 【REC】 | Query and print Weight Record. |

| 【PRINT】 | Print. |

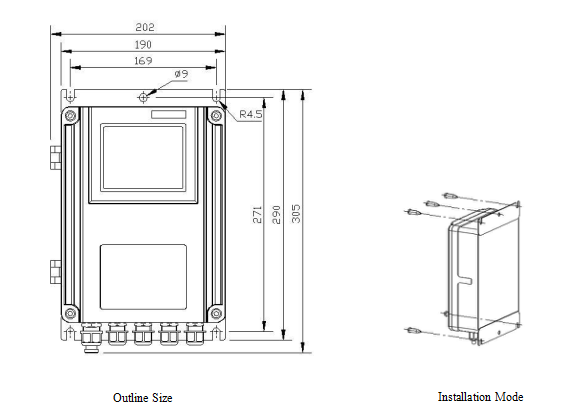

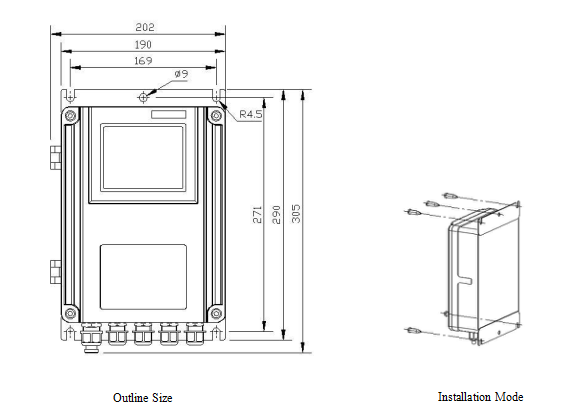

Installation:

Model Horizontal Panel-mounting Terminal:

Model Wall-mounting Operation Interface:

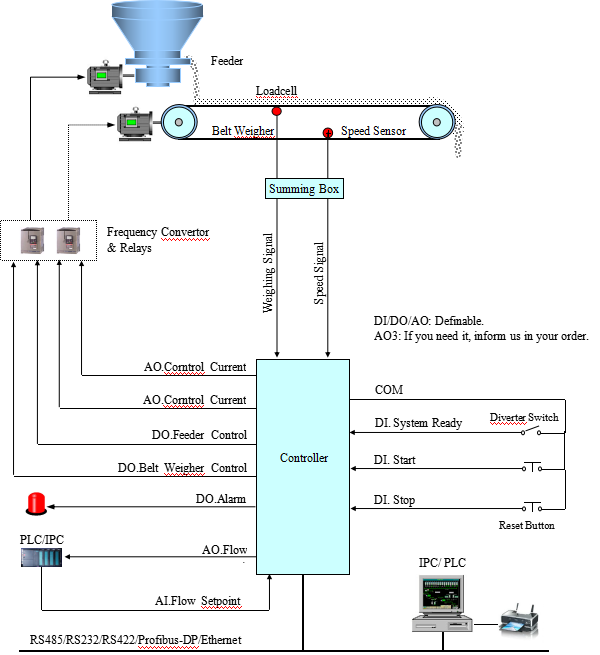

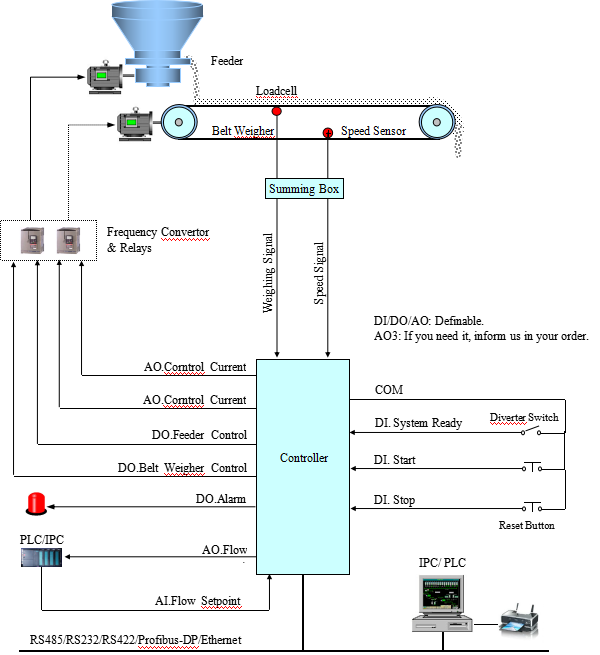

Ration Flow Auto-Feeding System: