Dongguan Jialisheng Refrigeration Equipment Co., Ltd. |

|

Verified Suppliers

|

|

JLSF-8HP Air Cooled Water Chiller Glass Reactor, Metal Reactor, Bioreactor, Cooling, Crystallization

Product Description:

Reactor chiller refers to a kind of chiller equipment used to cool

the reactor. Reactor is a commonly used reaction equipment in

chemical, pharmaceutical, food and other industries. It needs to be

heated or cooled inside. In order to control the temperature of the

reaction and ensure the quality of the reaction, it is necessary to

use a chiller to provide cooling water for the reactor.

Production Features:

The main features of the reactor chiller are:

1. High precision of temperature control: The reactor chiller can precisely control the temperature of the reactor by controlling the temperature and flow of cooling water to ensure the quality and stability of the reaction.

2. High cooling efficiency: The reactor chiller can quickly reduce the temperature inside the reactor, speed up the reaction and improve the efficiency of the reaction.

3. Compact equipment structure: The reactor chiller generally adopts a compact structure design, which can occupy less space and is convenient for installation and use.

4. Easy to operate: The operation of the reactor chiller is relatively simple, only need to adjust the temperature and flow of cooling water to realize the control of the reactor.

Reactor chillers have been widely used in chemical, pharmaceutical, food and other industries. They can provide a stable cooling water source for reactors, ensure the quality and efficiency of reactions, improve production efficiency and reduce production costs.

Working Principle:

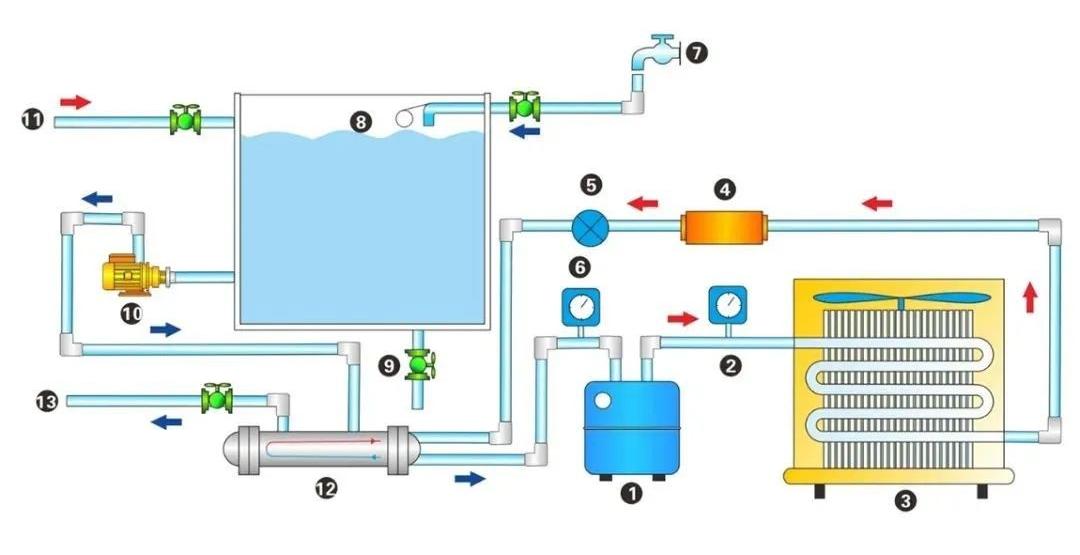

The main components of an air-cooled chiller include a compressor, an air condenser, an expansion valve, and an evaporator. Here is a basic overview of its workflow:

1.The compressor takes in low-pressure, low-temperature refrigerant

gas and compresses it into high-pressure, high-temperature gas.

2.This high-temperature, high-pressure refrigerant gas enters the

air condenser, exchanges heat with the ambient air, and discharges

heat to the environment, while the refrigerant condenses from a

gaseous state to a liquid state.

3.The high-pressure refrigerant liquid passes through the expansion

valve, the pressure suddenly drops, and it turns into a

low-pressure and low-temperature refrigerant liquid.

4.The low-temperature and low-pressure refrigerant liquid enters

the evaporator, absorbs indoor heat, evaporates into a gaseous

state by itself, and the indoor temperature drops to achieve the

purpose of refrigeration.

5.The refrigerant gas is sucked into the compressor again to

complete a cycle.

The advantages of air-cooled chillers include simple installation, no need for cooling towers and cooling water pumps, and low maintenance costs. However, its efficiency is lower than that of water-cooled chillers, especially at high ambient temperatures, and its efficiency will be further reduced

| ① Compressor | ⑤ Evaporator | ⑨ Temperature sensor | ⑬ Bypass valve |

| ② Condenser | ⑥ Ball valve | ⑩ Water tank | ⑭ Low voltage controller |

| ③ Filter drier | ⑦ Antifreeze switch | ⑪ Water pump pressure gauge | ⑮ High voltage controller |

| ④ Expansion valve | ⑧ Float switch | ⑫ Water pump | ⑯ Pressure relief valve |

Techinical Parameters:

| Model | JLSF-1HP | JLSF-2HP | JLSF-3HP | JLSF-4HP | JLSF-5HP | JLSF-6HP | JLSF-8HP | JLSF-10HP | ||

| Cooling capacity | KW/h | 3.1 | 6.2 | 9.3 | 12.4 | 15.5 | 18.6 | 24.8 | 31 | |

| Kcal/h | 2,700 | 5,400 | 8,100 | 10,800 | 13,500 | 16,200 | 21,600 | 27,000 | ||

| Temperature range | 5℃-35℃(Below 0℃ can be customized) | |||||||||

| Power supply | 1PH-220V 50HZ/60HZ 3PH-380V/415V 50HZ/60HZ | |||||||||

| Total power | KW | 1.21 | 2.03 | 2.84 | 3.7 | 4.5 | 5.7 | 7.33 | 8.83 | |

| Compressor | Type | Hermetic scroll type or piston | ||||||||

| Power | KW | 0.75 | 1.50 | 2.25 | 3.00 | 3.75 | 4.50 | 6.00 | 7.50 | |

| Circulating pump | Power | KW | 0.375 | 0.375 | 0.375 | 0.375 | 0.75 | 0.75 | 0.75 | 1.5 |

| Head | m | 22 | 22 | 22 | 22 | 23 | 23 | 23 | 21.5 | |

| Refrigerant | Type | R22/R407c/R134a/R410a | ||||||||

| Control method | Temperature Sensing External Pressure Equalizing Expansion Valve | |||||||||

| filling volume | Kg | 0.50 | 1.00 | 1.50 | 2.00 | 2.50 | 3.00 | 4.00 | 5.00 | |

| Evaporator | Flow | m³/h | 0.82 | 0.98 | 1.45 | 1.88 | 2.42 | 2.92 | 3.75 | 4.85 |

| water capacity | m³ | 0.028 | 0.04 | 0.05 | 0.05 | 0.065 | 0.065 | 0.13 | 0.18 | |

| Diameter | inch | 1/2" | 3/4" | 1" | 1-1/2" | 1-1/2" | ||||

| Condensator | Type | Efficient brass sets corrugated aluminum fin | ||||||||

| Fan | Type | Axial flow | ||||||||

| air volume | m³/h | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | |

| Protective device | High and low pressure switch, antifreeze protection, fusible plug/safety valve, overload protection device, coil overheat protector, automatic temperature protection switch, etc. | |||||||||

| Machine size | L | mm | 680 | 800 | 1040 | 1140 | 1140 | 1200 | 1400 | 1400 |

| W | mm | 420 | 480 | 555 | 620 | 620 | 650 | 725 | 725 | |

| H | mm | 720 | 850 | 1060 | 1200 | 1200 | 1160 | 1450 | 1450 | |

| Unit weight | Kg | 60 | 90 | 130 | 140 | 170 | 210 | 270 | 350 | |

| Model | JLSF-12HP | JLSF-15HP | JLSF-20HP | JLSF-25HP | JLSF-30HP | JLSF-40HP | JLSF-50HP | JLSF-60HP | ||

| Cooling capacity | KW/h | 37.2 | 46.5 | 65 | 77.5 | 93 | 124 | 155 | 186 | |

| Kcal/h | 29,059 | 37,965 | 50,805 | 61,683 | 74,992 | 97,675 | 116,521 | 156,249 | ||

| Temperature range | 5℃-35℃(Below 0℃ can be customized) | |||||||||

| Power supply | 1N-220V 50HZ/60HZ 3N-380V/415V 50HZ/60HZ | |||||||||

| Total power | KW | 11.4 | 13.62 | 19.8 | 22.75 | 28.3 | 39.2 | 46.75 | 56.1 | |

| Compressor | Type | Hermetic scroll type or piston | ||||||||

| Power | KW | 9 | 11.25 | 15 | 18.75 | 22.5 | 30 | 37.5 | 45 | |

| Circulating pump | Power | KW | 1.5 | 1.5 | 2.2 | 2.2 | 4 | 4 | 4 | 5.5 |

| Head | m | 21.5 | 21.5 | 22 | 22 | 25 | 25 | 25 | 26 | |

| Refrigerant | Type | R22/R407c/R134a/R410a | ||||||||

| Control method | Temperature Sensing External Pressure Equalizing Expansion Valve | |||||||||

| filling volume | Kg | 7.2 | 9.1 | 12.2 | 15.3 | 18.6 | 24.5 | 30.6 | 36.8 | |

| Evaporator | Flow | m³/h | 5.81 | 7.6 | 10.16 | 12.34 | 15.2 | 19.53 | 23.3 | 30.52 |

| water capacity | m³/h | 0.18 | 0.21 | 0.28 | 0.32 | 0.32 | 0.61 | 0.66 | 0.72 | |

| Diameter | inch | 1.5" | 2" | 2.5" | 3" | |||||

| Condensator | Type | Efficient brass sets corrugated aluminum fin | ||||||||

| Fan | Type | Axial flow | ||||||||

| air volume | m³/h | 12000 | 15000 | 20000 | 25000 | 30000 | 40000 | 50000 | 60000 | |

| Protective device | High and low pressure switch, antifreeze protection, fusible plug/safety valve, overload protection device, coil overheat protector, automatic temperature protection switch, etc. | |||||||||

| Machine size | L | mm | 1400 | 1750 | 2000 | 2000 | 2200 | 2000 | 2000 | 2400 |

| W | mm | 725 | 750 | 900 | 900 | 900 | 1800 | 1800 | 1800 | |

| H | mm | 1450 | 1500 | 1770 | 1770 | 1770 | 2200 | 2300 | 2300 | |

| Unit weight | Kg | 370 | 480 | 590 | 590 | 880 | 1000 | 1280 | 1420 | |

Application Industry:

Small air-cooled chillers are suitable for many different industries and applications, including but not limited to the following:

1.Electronics industry: Small air-cooled chillers can provide refrigeration for high-tech products such as semiconductors, optics, and electronic components to ensure the normal operation of the equipment.

2.Pharmaceutical industry: small air-cooled chillers can provide stable cooling effect for the link in the pharmaceutical production process that requires temperature control, ensuring the quality and safety of pharmaceuticals.

3.Food industry: Small air-cooled chillers can provide refrigeration for the links that require temperature control during food processing, storage and transportation to ensure the quality and safety of food.

4.Plastic industry: small air-cooled chillers can provide refrigeration for the temperature-controlled links in plastic injection molding, blow molding, extrusion molding, etc., to ensure product quality and production efficiency.

5.Chemical industry: small air-cooled chillers can provide refrigeration for the links that need temperature control in the chemical production process to ensure the quality and safety of chemical products.

In general, small air-cooled chillers are suitable for various occasions that require refrigeration, and provide efficient, stable and reliable refrigeration solutions for different industries.

Automotive Manufacturing

Chemical Engineering

Electronics Industry

Electroplating Industry

Injection Molding Industry Pharmaceutical Industry Plastic Packaging Industry Printing Industry

Upport and Services:

Air Cooled Chiller technical support and service includes:

1. 24/7 customer support

2. Remote guidance installation and maintenance

3. Remote Diagnostics and Troubleshooting

4. Phone/Email Advice and Guidance

5. User friendly documentation and manuals

6. Software Updates and Upgrades

7. Cost price of spare parts and consumables

Packing and Shipping:

Air-cooled chillers are packaged and shipped in standard plywood wooden boxes. All components are secured and protected with a film, and the unit is then placed on a pallet for easy transport. And affix the shipping mark information label on the wooden box to ensure correct delivery.

Precautions for Reactor Chiller

The following points should be paid attention to when using the reactor chiller:

1. Confirm the cooling requirements of the reactor: Different reactors have different cooling requirements. It is necessary to determine the cooling temperature, flow rate and pressure of the reactor according to the specific reactor type and the nature of the reactants.

2. Choose a suitable cooling medium: Different reactors need to use different cooling media, for example, some reactors need to use distilled water as cooling medium, while some reactors need to use coolant. It is necessary to select a suitable cooling medium according to the specific reactor type and reactant properties.

3. Confirm the water quality of the cooling water: the cooling water of the reactor needs to ensure that the water quality is clean, free of impurities and microorganisms, so as to ensure the sanitation inside the reactor and the quality of the reaction. The water quality of the reactor cooling water needs to be tested regularly, and cleaned and disinfected as needed.

4. Pay attention to the cooling water circulation system: the reactor chiller needs to be connected to the reactor cooling system, and attention should be paid to the design and installation of the cooling water circulation system to ensure the stability of the cooling water flow and pressure parameters.

5. Regular maintenance and maintenance: The reactor chiller needs regular maintenance and maintenance, including cleaning the cooling water system, replacing cooling water and filters, etc., to ensure the normal operation of the equipment and prolong its service life.

6. Safe operation: When using the reactor chiller, it is necessary to follow the safe operation rules to ensure the safe operation of the equipment and avoid possible safety hazards.

To sum up, the above points need to be paid attention to when using the reactor chiller to ensure the cooling effect of the reactor and the quality of the reaction. At the same time, attention should be paid to safe operation and regular maintenance.