Dongguan Jialisheng Refrigeration Equipment Co., Ltd. |

|

Verified Suppliers

|

|

JLSS-70HP Water Cooled Water Chiller Sheet Metal Stamping, Casting, Welding, plastic injection molding

Product Description:

Three chillers integrated machine is a device that integrates three

independent chillers in one chassis or cabinet. It is designed to

provide increased cooling capacity and redundancy to meet the needs

of large data centers, industrial manufacturing and other

large-scale applications.

Production Features:

The following are the main features and functions of the three integrated chillers:

1. High cooling capacity: By integrating three chillers together, the three chillers integrated machine can provide greater cooling capacity. This is beneficial in scenarios that require significant cooling, such as high-density server rooms or industrial manufacturing processes with high heat loads.

2. Redundant design: Three integrated chillers usually have a redundant design to ensure that when one chiller fails, the other two can continue to provide cooling capacity. This redundancy increases system reliability and stability, reducing the risk of downtime due to single points of failure.

3. Compact space utilization: Integrating three chillers in one case or cabinet can significantly save space. This is extremely valuable where space is limited or multiple chillers are required. At the same time, the integrated design also simplifies the pipeline connection and system layout, reducing the complexity of installation and maintenance.

4. Unified control system: Three integrated chillers are usually equipped with a unified control system for monitoring and controlling the entire system. Through centralized management, the operating status and parameters of each chiller can be easily monitored and adjusted to achieve coordinated operation and optimize energy efficiency.

5. Customizable configuration: Three integrated chillers can usually be customized according to customer needs. This includes cooling capacity, cooling medium, control methods and additional functions, etc. Customization to specific needs ensures optimum adaptability and performance.

Three chillers integrated all-in-one is an efficient, reliable and flexible cooling solution that can meet the cooling needs of large applications and provide redundant backup to ensure the continuity and stability of the system.

Working Principle:

The working principle of the three chillers integrated machine is as follows:

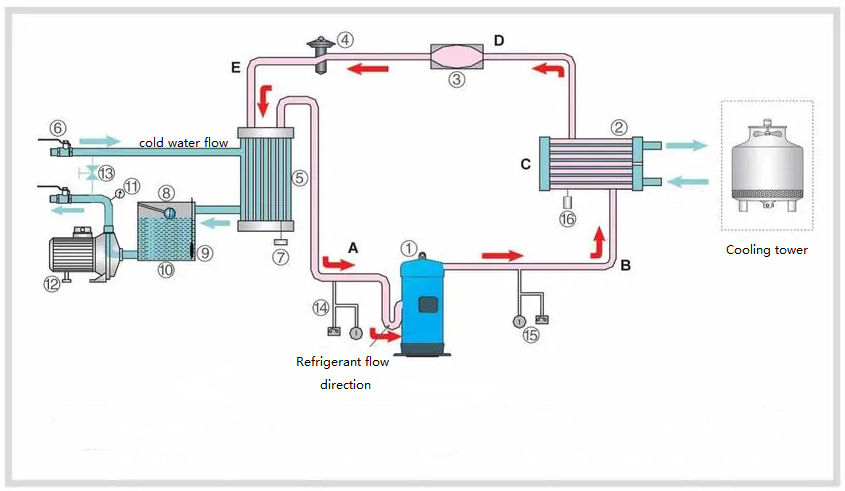

1. Refrigeration cycle: Each chiller contains a refrigeration cycle, including compressor, evaporator, condenser and expansion valve. A refrigeration cycle uses a refrigerant (usually a refrigerant fluid) to transfer heat and achieve cooling. The refrigerant undergoes a phase change during the cycle, absorbs heat from the evaporator in a low-pressure, low-temperature state, and then releases heat in a condenser in a high-pressure, high-temperature state.

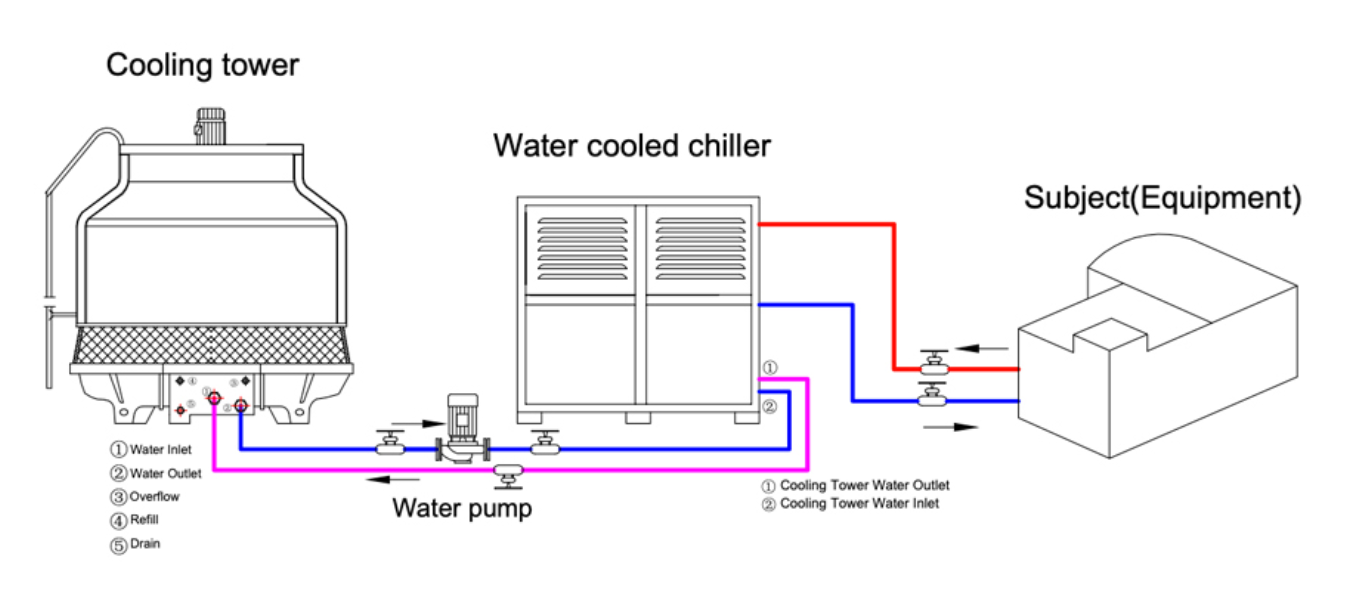

2. Cooling tower: Three chillers are usually equipped with a cooling tower system. Cooling towers remove heat by spraying a cooling medium (usually water) onto the top of the tower and using air to transfer heat to the cooling medium. When the cooling medium in the cooling tower is in contact with the air, it dissipates heat through evaporation and conduction, and gradually reduces its temperature. The function of the cooling tower is to reduce the temperature of the cooling medium so that it can be circulated back to the evaporator of the chiller.

3. Water pump: Three chillers are usually equipped with a water pump system. The water pump is responsible for drawing cooling water from the cooling tower and sending it back to the chiller's evaporator. The water pump promotes the circulation of the cooling water by providing sufficient pressure and flow to ensure that the cooling water can effectively absorb heat and participate in the refrigeration cycle.

① Compressor | ⑤ Evaporator | ⑨ Temperature sensor | ⑬ Bypass valve |

② Condenser | ⑥ Ball valve | ⑩ Water tank | ⑭ Low voltage controller |

③ Filter drier | ⑦ Antifreeze switch | ⑪ Water pump pressure gauge | ⑮ High voltage controller |

④ Expansion valve | ⑧ Float switch | ⑫ Water pump | ⑯ Pressure relief valve |

Techinical Parameters:

| Model | JLSS-5HP | JLSS-10HP | JLSS-15HP | JLSS-20HP | JLSS-25HP | JLSS-30HP | JLSS-40HP | JLSS-50HP | ||

| Cooling capacity | KW/h | 16.2 | 32.5 | 48.7 | 64.2 | 81.2 | 97.4 | 130.3 | 163.4 | |

| Kcal/h | 14,200 | 28,400 | 42,600 | 56,800 | 71,000 | 85,200 | 113,600 | 142,000 | ||

| Temperature range | 5℃-35℃(Below 0℃ can be customized) | |||||||||

| Power supply | 1PH-220V 50HZ/60HZ 3PH-380V/415V 50HZ/60HZ | |||||||||

| Total power | KW | 4.17 | 8.25 | 12.75 | 18.2 | 20.95 | 26.5 | 35.6 | 43.2 | |

| Compressor | Type | Hermetic scroll type or piston | ||||||||

| Power | KW | 3.75 | 7.5 | 11.25 | 15.0 | 18.75 | 22.5 | 30.0 | 37.5 | |

| Circulating pump | Power | KW | 0.75 | 1.5 | 1.5 | 2.25 | 2.25 | 3.75 | 3.75 | 3.75 |

| Head | m | 22 | 21.5 | 21.5 | 23 | 23 | 23 | 25 | 25 | |

| Refrigerant | Type | R22/R407c/R134a/R410a | ||||||||

| Control method | Temperature Sensing External Pressure Equalizing Expansion Valve | |||||||||

| filling volume | Kg | 2.6 | 5.2 | 7.8 | 10.4 | 13.0 | 15.6 | 20.8 | 26.0 | |

| Evaporator | Flow | m³/h | 2.75 | 5.47 | 8.62 | 11.55 | 14.03 | 17.06 | 22.19 | 26.48 |

| water capacity | m³ | 0.058 | 0.150 | 0.285 | 0.300 | 0.380 | 0.380 | 0.560 | 0.560 | |

| Diameter | inch | 1" | 1.5" | 2" | 2.5" | 2.5" | 3" | 3" | 3" | |

| Compressor | Type | m³/h | Efficient copper shell and tube type | |||||||

| Flow | m³/h | 3.42 | 6.85 | 10.78 | 14.44 | 17.54 | 21.32 | 27.74 | 33.09 | |

| Diameter | inch | 1" | 1.5" | 2" | 2.5" | 2.5" | 3" | 3" | 3" | |

| Protective device | High and low pressure switch, antifreeze protection, fusible plug/safety valve, overload protection device, coil overheat protector, automatic temperature protection switch, etc. | |||||||||

| Machine size | L | mm | 850 | 1300 | 1600 | 1600 | 1600 | 1800 | 2400 | 2400 |

| W | mm | 480 | 610 | 700 | 730 | 730 | 760 | 1000 | 1000 | |

| H | mm | 980 | 1260 | 1400 | 1500 | 1500 | 1600 | 1750 | 1750 | |

| Unit weight | Kg | 60 | 150 | 400 | 440 | 690 | 760 | 850 | 1000 | |

Application Industry:

Water-cooled chillers are widely used in many industries, including but not limited to the following industries:

1. Construction and commercial fields: Water-cooled chillers are often used in air-conditioning systems in buildings, commercial office buildings, shopping centers, hotels and other places to provide cooling water sources to adjust indoor temperature and humidity and maintain a comfortable indoor environment.

2. Manufacturing and industrial fields: Many production processes in the manufacturing and industrial fields require cooling equipment or coolants to maintain the normal operating temperature of the equipment, and water-cooled chillers are often used in these applications, such as metal processing, plastic injection molding, laser cutting , electronics manufacturing and other fields.

3. Medical and pharmaceutical fields: Medical facilities and the pharmaceutical industry need to precisely control the temperature in laboratories, operating rooms, pharmaceutical production, etc. Water-cooled chillers can provide a stable cooling water source to meet the needs of medical equipment and pharmaceutical processes .

4. Information technology and communication fields: Information technology and communication facilities such as data centers, server rooms, and telecommunication base stations require cooling equipment to control the temperature of the equipment and ensure its normal operation. Water-cooled chillers are widely used in these facilities.

5. Laboratories and scientific research institutions: Experimental equipment, instruments and facilities in laboratories and scientific research institutions usually require precise temperature control. Water-cooled chillers can provide laboratories with a stable cooling water source to meet the requirements of experiments and research.

6. Food and beverage industry: During food and beverage processing, it is necessary to control product temperature and maintain hygienic conditions. Water-cooled chillers can be used to cool and maintain the quality and safety of food and beverages.

These industries are just a part of the application of water-cooled chillers, in fact they play an important cooling function in various industries. Specific applications will vary depending on industry needs and specific scenarios.

Automotive Manufacturing

Chemical Engineering

Electronics Industry

Electroplating Industry

Injection Molding Industry Pharmaceutical Industry Plastic Packaging Industry Printing Industry

Upport and Services:

Chiller technical support and service includes:

1. 24/7 customer support

2. Remote guidance installation and maintenance

3. Remote Diagnostics and Troubleshooting

4. Phone/Email Advice and Guidance

5. User friendly documentation and manuals

6. Software Updates and Upgrades

7. Cost price of spare parts and consumables

Packing and Shipping:

Chillers are packaged and shipped in standard plywood wooden boxes. All components are secured and protected with a film, and the unit is then placed on a pallet for easy transport. And affix the shipping mark information label on the wooden box to ensure correct delivery.

How does a water-cooled chiller shorten the injection molding cycle and improve production efficiency in the plastic injection molding process?

In the plastic injection molding process, water-cooled chillers can take the following measures to shorten the injection molding cycle and improve production efficiency:

1. Rapid cooling of the mold: The cooling of the injection mold is one of the important factors affecting the injection cycle. By using the cooling water source provided by the water-cooled chiller, the cooling water can be circulated into the cooling channel of the mold to rapidly cool the plastic material and accelerate the solidification process of the plastic. Rapid cooling can shorten the plastic injection molding cycle, so that the time of each injection molding cycle is reduced, thereby improving production efficiency.

2. Control the cooling water temperature and flow rate: By adjusting the cooling water temperature and flow rate of the water-cooled chiller, the cooling effect of the injection mold can be precisely controlled. Appropriate cooling water temperature and flow can improve cooling efficiency and ensure rapid cooling and solidification of plastic materials, thereby shortening the injection molding cycle.

3. Use a cooler to cool the plastic injection machine: In addition to cooling the mold, a water-cooled chiller can also be used to provide a cooling water source to cool the hydraulic system and injection barrel of the injection molding machine to prevent the equipment from overheating. Maintaining a constant operating temperature of the injection molding machine can improve the stability and reliability of the equipment, reduce downtime, and further improve production efficiency.

4. Optimizing the cooling system design: The cooling system design of the injection mold is also a key factor affecting the injection molding cycle. By rationally designing the layout and size of the cooling channel, the cooling water can flow through the hot spots in the mold evenly and quickly, improving the cooling effect. Reasonable cooling system design can minimize the cooling time of plastic materials, thereby shortening the injection molding cycle.

Through the above measures, the water-cooled chiller can provide an efficient cooling water source, accelerate the cooling and solidification process of plastic materials, thereby shortening the injection molding cycle. Shortening the injection molding cycle can increase production capacity, improve production efficiency, reduce production costs, and meet customer needs for fast delivery.