Dongguan Jialisheng Refrigeration Equipment Co., Ltd. |

|

Verified Suppliers

|

|

JLSF-30HP Air Cooled Water Chiller Photovoltaic, Lithium Battery, Hydrogen Energy, Biomass Energy Manufacturing

Product Description:

An air-cooled chiller is an air-cooled chiller typically used in air conditioning systems in industrial or commercial buildings. Its working principle is to use a fan to blow outdoor air into the inside of the chiller, absorb indoor heat through water circulation, and then circulate the cooled water back into the room for cooling.

Compared with water-cooled chillers, air-cooled chillers do not require additional water cooling systems, so installation and maintenance are simpler and more economical. However, its cooling efficiency is affected by conditions such as outdoor temperature and humidity, and generally requires greater cooling power to achieve the same cooling effect.

Air-cooled chillers can usually be modularized according to needs to adapt to refrigeration and air conditioning systems of different sizes. It can also be combined with other heat recovery equipment, such as air source heat pumps or waste heat recovery units, to increase energy efficiency.

Product Features:

The side air chiller is a kind of refrigeration equipment, its main features include:

1. Side air outlet design: The air outlet of the side air chiller is located on the side of the equipment, which can directly send cold air to the equipment or space that needs to be cooled, thus improving the cooling efficiency.

2. Energy saving and environmental protection: the side air chiller adopts high-efficiency energy-saving compressors and high-efficiency heat exchangers, which can achieve energy-saving and environmental protection cooling effects.

3. Stable and reliable: The side air chiller adopts advanced refrigeration technology and control system, which can ensure the stability and reliability of the equipment.

4. Easy installation and maintenance: The side air chiller is small in size, very convenient for installation and maintenance, and can save installation space and maintenance costs.

5. Wide range of applications: side air chillers are suitable for various industries and fields, such as air-conditioning refrigeration, process refrigeration and equipment cooling in air-conditioning manufacturing, computer rooms, hospitals, electric power, metallurgy, chemical industry and other fields.

6. Multiple models: There are various models and specifications of side air chillers to choose from, which can be selected according to different application requirements to meet the cooling needs of different occasions.

To sum up, the side air chiller has the characteristics of high cooling efficiency, energy saving and environmental protection, stability and reliability, convenient installation and maintenance, and wide application, which can meet the cooling needs of various industries and fields.

Working Principle:

The main components of an air-cooled chiller include a compressor, an air condenser, an expansion valve, and an evaporator. Here is a basic overview of its workflow:

1.The compressor takes in low-pressure, low-temperature refrigerant

gas and compresses it into high-pressure, high-temperature gas.

2.This high-temperature, high-pressure refrigerant gas enters the

air condenser, exchanges heat with the ambient air, and discharges

heat to the environment, while the refrigerant condenses from a

gaseous state to a liquid state.

3.The high-pressure refrigerant liquid passes through the expansion

valve, the pressure suddenly drops, and it turns into a

low-pressure and low-temperature refrigerant liquid.

4.The low-temperature and low-pressure refrigerant liquid enters

the evaporator, absorbs indoor heat, evaporates into a gaseous

state by itself, and the indoor temperature drops to achieve the

purpose of refrigeration.

5.The refrigerant gas is sucked into the compressor again to

complete a cycle.

The advantages of air-cooled chillers include simple installation, no need for cooling towers and cooling water pumps, and low maintenance costs. However, its efficiency is lower than that of water-cooled chillers, especially at high ambient temperatures, and its efficiency will be further reduced

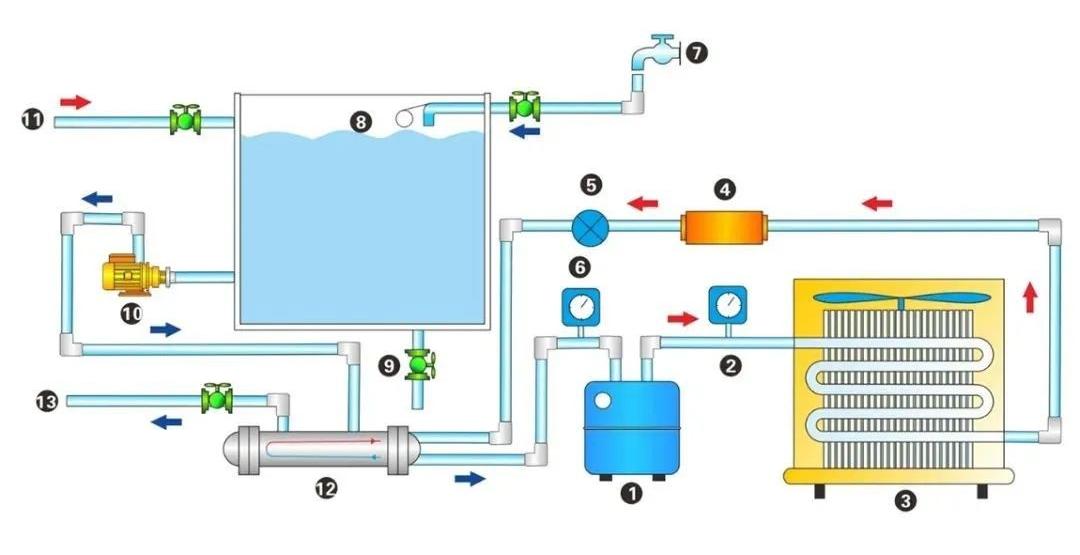

| ① Compressor | ⑤ Evaporator | ⑨ Temperature sensor | ⑬ Bypass valve |

| ② Condenser | ⑥ Ball valve | ⑩ Water tank | ⑭ Low voltage controller |

| ③ Filter drier | ⑦ Antifreeze switch | ⑪ Water pump pressure gauge | ⑮ High voltage controller |

| ④ Expansion valve | ⑧ Float switch | ⑫ Water pump | ⑯ Pressure relief valve |

Techinical Parameters:

| Model | JLSF-1HP | JLSF-2HP | JLSF-3HP | JLSF-4HP | JLSF-5HP | JLSF-6HP | JLSF-8HP | JLSF-10HP | ||

| Cooling capacity | KW/h | 3.1 | 6.2 | 9.3 | 12.4 | 15.5 | 18.6 | 24.8 | 31 | |

| Kcal/h | 2,700 | 5,400 | 8,100 | 10,800 | 13,500 | 16,200 | 21,600 | 27,000 | ||

| Temperature range | 5℃-35℃(Below 0℃ can be customized) | |||||||||

| Power supply | 1PH-220V 50HZ/60HZ 3PH-380V/415V 50HZ/60HZ | |||||||||

| Total power | KW | 1.21 | 2.03 | 2.84 | 3.7 | 4.5 | 5.7 | 7.33 | 8.83 | |

| Compressor | Type | Hermetic scroll type or piston | ||||||||

| Power | KW | 0.75 | 1.50 | 2.25 | 3.00 | 3.75 | 4.50 | 6.00 | 7.50 | |

| Circulating pump | Power | KW | 0.375 | 0.375 | 0.375 | 0.375 | 0.75 | 0.75 | 0.75 | 1.5 |

| Head | m | 22 | 22 | 22 | 22 | 23 | 23 | 23 | 21.5 | |

| Refrigerant | Type | R22/R407c/R134a/R410a | ||||||||

| Control method | Temperature Sensing External Pressure Equalizing Expansion Valve | |||||||||

| filling volume | Kg | 0.50 | 1.00 | 1.50 | 2.00 | 2.50 | 3.00 | 4.00 | 5.00 | |

| Evaporator | Flow | m³/h | 0.82 | 0.98 | 1.45 | 1.88 | 2.42 | 2.92 | 3.75 | 4.85 |

| water capacity | m³ | 0.028 | 0.04 | 0.05 | 0.05 | 0.065 | 0.065 | 0.13 | 0.18 | |

| Diameter | inch | 1/2" | 3/4" | 1" | 1-1/2" | 1-1/2" | ||||

| Condensator | Type | Efficient brass sets corrugated aluminum fin | ||||||||

| Fan | Type | Axial flow | ||||||||

| air volume | m³/h | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | |

| Protective device | High and low pressure switch, antifreeze protection, fusible plug/safety valve, overload protection device, coil overheat protector, automatic temperature protection switch, etc. | |||||||||

| Machine size | L | mm | 680 | 800 | 1040 | 1140 | 1140 | 1200 | 1400 | 1400 |

| W | mm | 420 | 480 | 555 | 620 | 620 | 650 | 725 | 725 | |

| H | mm | 720 | 850 | 1060 | 1200 | 1200 | 1160 | 1450 | 1450 | |

| Unit weight | Kg | 60 | 90 | 130 | 140 | 170 | 210 | 270 | 350 | |

| Model | JLSF-12HP | JLSF-15HP | JLSF-20HP | JLSF-25HP | JLSF-30HP | JLSF-40HP | JLSF-50HP | JLSF-60HP | ||

| Cooling capacity | KW/h | 37.2 | 46.5 | 65 | 77.5 | 93 | 124 | 155 | 186 | |

| Kcal/h | 29,059 | 37,965 | 50,805 | 61,683 | 74,992 | 97,675 | 116,521 | 156,249 | ||

| Temperature range | 5℃-35℃(Below 0℃ can be customized) | |||||||||

| Power supply | 1N-220V 50HZ/60HZ 3N-380V/415V 50HZ/60HZ | |||||||||

| Total power | KW | 11.4 | 13.62 | 19.8 | 22.75 | 28.3 | 39.2 | 46.75 | 56.1 | |

| Compressor | Type | Hermetic scroll type or piston | ||||||||

| Power | KW | 9 | 11.25 | 15 | 18.75 | 22.5 | 30 | 37.5 | 45 | |

| Circulating pump | Power | KW | 1.5 | 1.5 | 2.2 | 2.2 | 4 | 4 | 4 | 5.5 |

| Head | m | 21.5 | 21.5 | 22 | 22 | 25 | 25 | 25 | 26 | |

| Refrigerant | Type | R22/R407c/R134a/R410a | ||||||||

| Control method | Temperature Sensing External Pressure Equalizing Expansion Valve | |||||||||

| filling volume | Kg | 7.2 | 9.1 | 12.2 | 15.3 | 18.6 | 24.5 | 30.6 | 36.8 | |

| Evaporator | Flow | m³/h | 5.81 | 7.6 | 10.16 | 12.34 | 15.2 | 19.53 | 23.3 | 30.52 |

| water capacity | m³/h | 0.18 | 0.21 | 0.28 | 0.32 | 0.32 | 0.61 | 0.66 | 0.72 | |

| Diameter | inch | 1.5" | 2" | 2.5" | 3" | |||||

| Condensator | Type | Efficient brass sets corrugated aluminum fin | ||||||||

| Fan | Type | Axial flow | ||||||||

| air volume | m³/h | 12000 | 15000 | 20000 | 25000 | 30000 | 40000 | 50000 | 60000 | |

| Protective device | High and low pressure switch, antifreeze protection, fusible plug/safety valve, overload protection device, coil overheat protector, automatic temperature protection switch, etc. | |||||||||

| Machine size | L | mm | 1400 | 1750 | 2000 | 2000 | 2200 | 2000 | 2000 | 2400 |

| W | mm | 725 | 750 | 900 | 900 | 900 | 1800 | 1800 | 1800 | |

| H | mm | 1450 | 1500 | 1770 | 1770 | 1770 | 2200 | 2300 | 2300 | |

| Unit weight | Kg | 370 | 480 | 590 | 590 | 880 | 1000 | 1280 | 1420 | |

Application Industry:

Air-cooled chillers are widely used in the following industries and fields:

1. Industrial manufacturing: Air-cooled chillers can provide refrigeration services for factories, manufacturing workshops, machinery and equipment, etc., keep indoor temperature and humidity stable, and ensure the normal operation of production lines.

2. Commercial buildings: Air-cooled chillers can provide cooling services for commercial buildings, such as large shopping malls, office buildings, hotels, hospitals, schools, etc., to ensure the comfort of the indoor environment.

3. Pharmaceutical industry: Air-cooled chillers can provide refrigeration services for reactors, centrifuges, etc. in the pharmaceutical process to ensure the stability and quality of the pharmaceutical process.

4. Food processing industry: Air-cooled chillers can provide refrigeration services for food processing equipment to ensure the hygiene and quality of food processing.

5. Shipbuilding industry: Air-cooled chillers can provide refrigeration services for ships, such as ship bridges and engine rooms, to ensure the normal and safe operation of ships.

In general, air-cooled chillers can provide refrigeration services for various industries and fields, ensuring the comfort of the indoor environment and the stability of the production process.

Automotive Manufacturing

Chemical Engineering

Electronics Industry

Electroplating Industry

Injection Molding Industry Pharmaceutical Industry Plastic Packaging Industry Printing Industry

Upport and Services:

Air Cooled Chiller technical support and service includes:

1. 24/7 customer support

2. Remote guidance installation and maintenance

3. Remote Diagnostics and Troubleshooting

4. Phone/Email Advice and Guidance

5. User friendly documentation and manuals

6. Software Updates and Upgrades

7. Cost price of spare parts and consumables

Packing and Shipping:

Air-cooled chillers are packaged and shipped in standard plywood wooden boxes. All components are secured and protected with a film, and the unit is then placed on a pallet for easy transport. And affix the shipping mark information label on the wooden box to ensure correct delivery.

What are the requirements for the chiller of the new energy battery production line?

The new energy battery production line chiller is designed to meet the temperature control requirements in the battery production process, and its main requirements include:

1. Stable and reliable: battery production is a highly sophisticated process with very high requirements on the production environment. Therefore, the chiller must have a stable and reliable cooling effect to ensure the stability and accuracy of the temperature during the production process.

2. High efficiency and energy saving: The battery production process requires a large amount of cooling capacity. Therefore, the chiller must have the characteristics of high efficiency and energy saving, which can reduce energy consumption while ensuring the cooling effect.

3. Precise temperature control: battery production requires precise temperature control, and the chiller must have a precise temperature control system to achieve high-precision temperature control.

4. High pressure: The battery production process requires a high-temperature and high-pressure environment. Therefore, the chiller must have high-pressure cooling capacity to meet the requirements of battery production.

5. Safe and reliable: Safety needs to be ensured in the battery production process, and the chiller must have multiple protection measures, such as over-current protection, overload protection, high-voltage protection, low-voltage protection, etc., to ensure the safe operation of the equipment.

6. Space saving: battery production lines usually take up a lot of space, so the chiller should be as small as possible to save space on the production line.

7. Ease of maintenance: Chillers need frequent maintenance and maintenance. Therefore, the design of chillers should be easy to maintain and maintain, which can reduce maintenance costs.

To sum up, the chillers in the new energy battery production line need to have the characteristics of stability and reliability, high efficiency and energy saving, precise temperature control, high pressure, safety and reliability, space saving and easy maintenance, so as to meet the temperature control requirements in the battery production process.