Suzhou Drimaker Machinery Technology Co., Ltd |

|

Verified Suppliers

|

|

1200BPH 3 Layers 5 Gallon Palletizer For Gallon Filling Machine PLC Control Stacker Crane

Automatic palletizer description:

In view of the shortage of labor resources and the high labor intensity of the workers in the drinking water plant, our factory successfully developed the 5 gallon automatic palletizer of the barrel water through the actual investigation of many manufacturers of the barrel water and the effective communication with customers. The equipment has less floor space and low operating cost. It can fold 1200 barrels of 5 gallon water bottles into three layers per hour (each layer is 4*4=16 barrels) as required. It can also be designed as 3*4=12 according to customers' requirements. 3 * 5 = 15).The whole equipment can be operated easily by only one person, which can reduce the labor intensity of employees and reduce the staffing of the entire production line to the greatest extent.

Palletizer features:

| No | Details |

| 1 | This machine adopts the chute type since gravity into the bottle and the state machine has no power consumption, energy consumption is extremely low; Built-in signal detection institutions close to stack according to automatically adjust the production speed and filling out the bottle line. |

| 2 | Mention bottle system adopts the latest design of pneumatic clamp bottle holder, it does not hurt the brim and shrinkage film, not to drop, gas consumption is small, stable operation. |

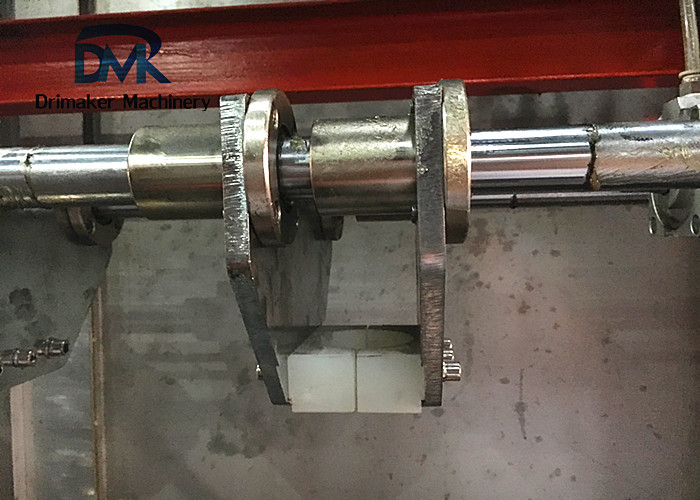

| 3 | The moving car which is holding bottle adopts double shaft transmission shift, effectively avoid the use of metal fatigue deformation due to foundation uneven, overload causes such as the car moving not free. |

| 4 | This machine can be stacked 1-3 layers, stacked layers can be adjusted on the touch screen, for different customer needs. |

| 5 | This machine adopts imported PLC microcomputer control, human-machine interface operation, operation parameters and process of action, are available on a touch screen free adjustment, has downtime, alarm, display, and other functions |

| 6 | Lifting system uses no rack and the chain type soft connection structure, with lifting speed stability, accidental fault mechanical protection function, the effective protection of the machine under the special failure since the protection function. |

| 7 | Limit position of the machine movement all has the dual protection, each limit position is set photoelectric detection protection switch, the machine is running, if detected anomaly detection points produced carved stop and alarm, the maximum extent to protect the safety of personnel and equipment. |

| 8 | The machine use numerical control technology to detect translational position, the bottle and put the bottle position quite accurate, avoid the shortcoming of the high failure rate caused by excessive use of position switches. Adopts frequency conversion motor drive, the bucket in the process of ascension and translation with high and low, speed operation in (high speed running in low speed clamp bottle - - put bottles) at low speed, plexus and coordination, make the whole operation process to run smoothly. |

Gallon filling machine parameters:

| No | Item | Details |

| 1 | Reduction gear system |

Gear motor, frequency conversion control |

| 2 | Electrical apparatus control system | Programmable controller (PLC) centralized control, touch screen operation, nc coder localization way |

| 3 | The bottle of operation mode | Numerical control period of speed, reduce, run faster, more speed variable frequency regulation |

| 4 | Air actuated control system | AIRTAG cylinder and solenoid valves, PLC centralized control |

| 5 | Protecting device | Photoelectric detection device for all the moving parts to parts for testing |

| 6 | Bottle feeding way | Gravity slide type into the bottle, automatic detection work |

| 7 | Chuck bottle system | The four sets of pneumatic type bottle clamp, 4 * 4 layout |

Thanks!

For more information please contact us!