GUANGZHOU CITY PENGDA MACHINERIES CO., LTD. |

|

Verified Suppliers

|

|

Energy-Saving Ice-cream cone Machinery High Quality Wafer Production Line

Key Features:

Double Layered Panel Door.

Hot air escapes from door top cold air move in from door bottom. Air inside door become heat insulator. It reduces heat loss from the oven, saving energy and keeping the panel cool.

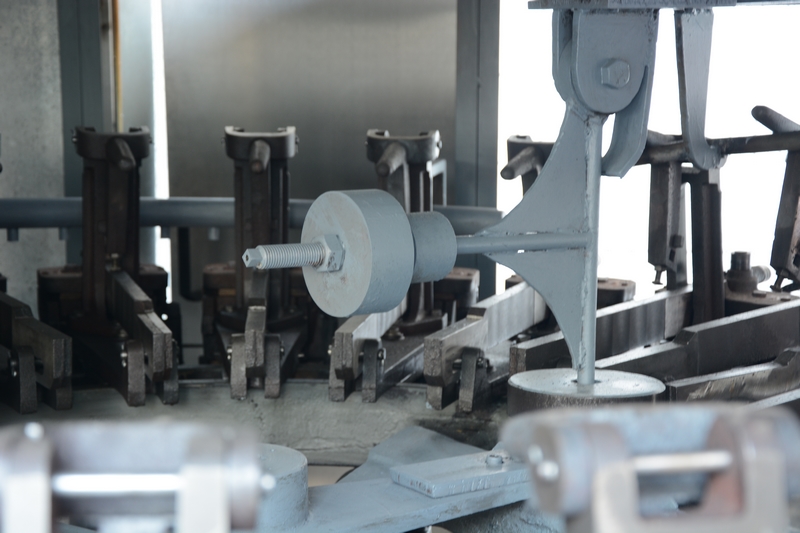

One Motor drives all.

One single motor synchronize the oven, batter pump and molds open & close actions using track and roller system. Easy to operate and maintain with a reliable production.

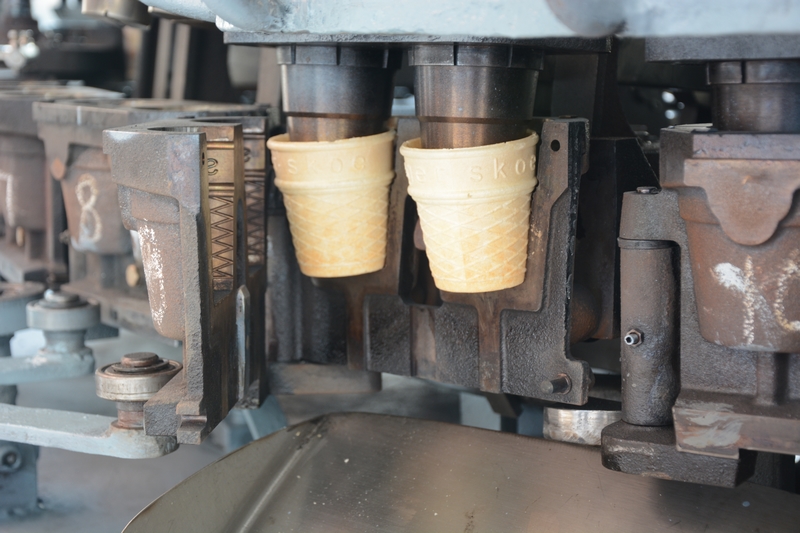

Cone Ejection.

Smooth cone ejection action by track and roller system. The hammer system ensure the wafer cone or cup ejected without difficulty.

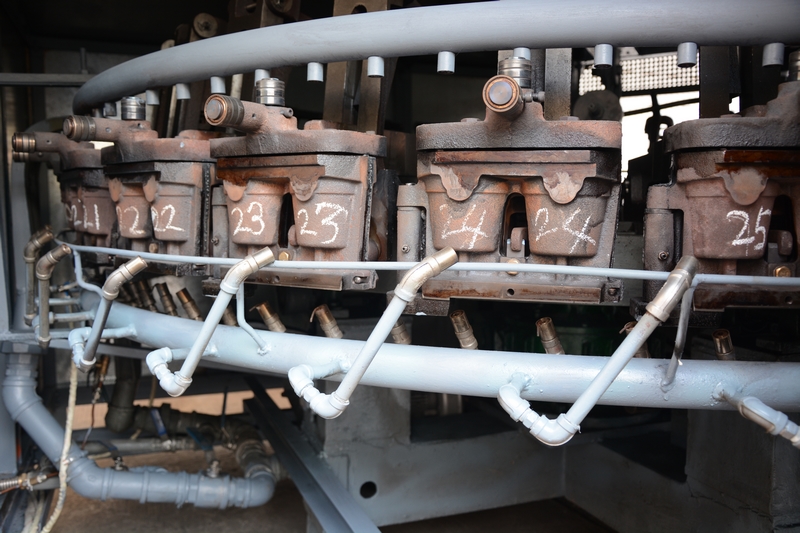

Cone Molds.

Material is QT500 nodular cast iron. It is superior to aluminum in durability. Carbon accumulation can be removed with ease. Mold design with minimum runner on the cone. Reasonable placement of air release give better cone appearance.

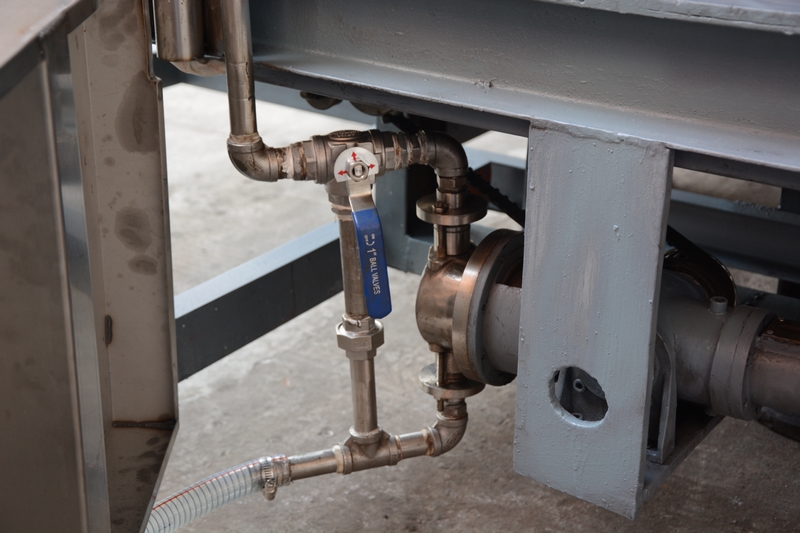

Batter Tank and Pump System.

Double walled to keep batter temperature stable. Steel sieve included. Backflow valve stop batter to release from doser while adjustable doser help control the wafer size.

Gas system.

3-ways burner nozzles arrangement provide even baking inside mold. Special design nozzle to give clear blue flames and increase energy efficiency. Universal burner allow LPG, natural gas and some other type fuel. Protection rail is built to prevent unpredictable impact on burner.

XT-28 Specification

| No.of Molds | 28molds |

| Cones/hour for Φ85mm or less*(one mold two cones) | 2200 |

| Cones/hour for Φ55mm or less*(one mold three cones) | 3300 |

| Cones/hour for Φ40mm or less*(one mold four cones) | 4400 |

| LPG Consumption/Hour | 4-5 |

| Machine Dimension(mm) | 3500L*3000W*2200H |

| Machine Weight(kg) | 4000 |

| Main Motor Specification | 1.0hp;0.75kW |

*Production output depends on the quality of cone mix, oven temperature and thickness of cone.