Anhui Keye Information & Technology Co., Ltd. |

|

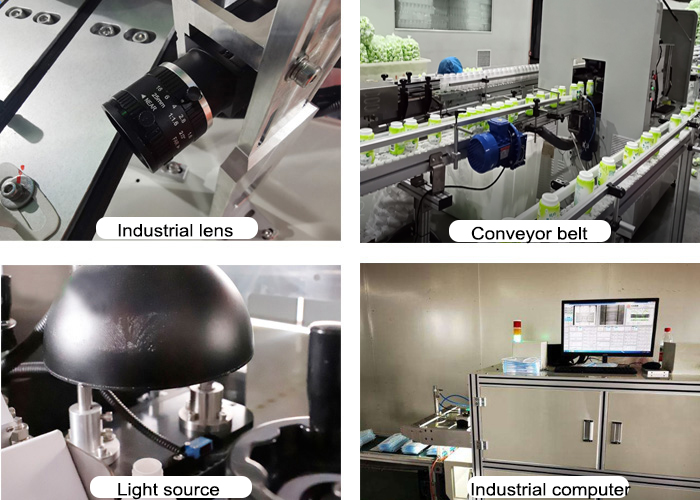

Machine Vision & Visual Inspection System In Modern Industrial Automatic Production

Equipment features:

1. AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2. Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3. Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4. High precision: detection accuracy can be high |

| 5. Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6. Easy to operate: It is easy to operate and easy to maintain |

| 7. Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

What is machine vision

The popularity of machine vision inspection systems abroad is mainly reflected in the semiconductor and electronics industries, of which about 40%-50% are concentrated in the semiconductor industry. Specifically, such as PCB printed circuit: various production printed circuit board assembly technologies and equipment; single-sided, double-sided, multi-layer circuit boards, copper-clad laminates and required materials and accessories; auxiliary facilities and consumables, inks, potions, accessories; electronics Packaging technology and equipment; screen printing equipment and screen peripheral materials, etc.

Machine vision inspection system has also been widely used in various aspects of quality inspection, and its products occupy a pivotal position in the application. In addition to this, machine vision inspection systems are also used in various other fields.

Inspection principle

Various inspection, production monitoring and part identification applications are involved in modern industrial automation production, such as dimensional inspection for batch processing of auto parts and integrity inspection for automatic assembly, automatic component positioning for electronic assembly lines, and character recognition on ICs Wait.

Usually this kind of highly repetitive and intelligent work is done by the naked eye, but in some special cases, such as accurate and fast measurement of tiny sizes, shape matching and color recognition, it is impossible to rely on the naked eye to continuously stabilize To carry out, other physical quantity sensors are also difficult to do.

Inspection details

People began to consider using a CCD camera to capture images and send them to a computer or a dedicated image processing module. Through digital processing, the size, shape, color, etc. can be discriminated based on information such as pixel distribution, brightness, and color. This method is to combine the rapidity and repeatability of computer processing with the highly intelligent and abstract ability of naked eye vision, resulting in the concept of machine vision testing technology.

Applications

Research shows that 65% of consumers refer to packaging when purchasing a product. If packaging is mislabeled or damaged, hiding potentially harmful ingredients, this can lead to product recalls, fines, and even legal action. Surveys have shown that 55% of recalls in the food industry are caused by incorrect labeling, and food allergens are a very common example.

The machine vision inspection system has been developed for more

than 20 years since its inception. Its functions and application

scope have been gradually improved and promoted with the

development of industrial automation, especially the current

digital image sensors, CMOS and CCD cameras, DSP, FPGA, The rapid

development of embedded technology such as ARM, image processing

and pattern recognition has greatly promoted the development of

machine vision.