Anhui Keye Information & Technology Co., Ltd. |

|

Equipment features:

| 1.AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2.Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3.Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4.High precision: detection accuracy can be high |

| 5.Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6.Easy to operate: It is easy to operate and easy to maintain |

| 7.Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

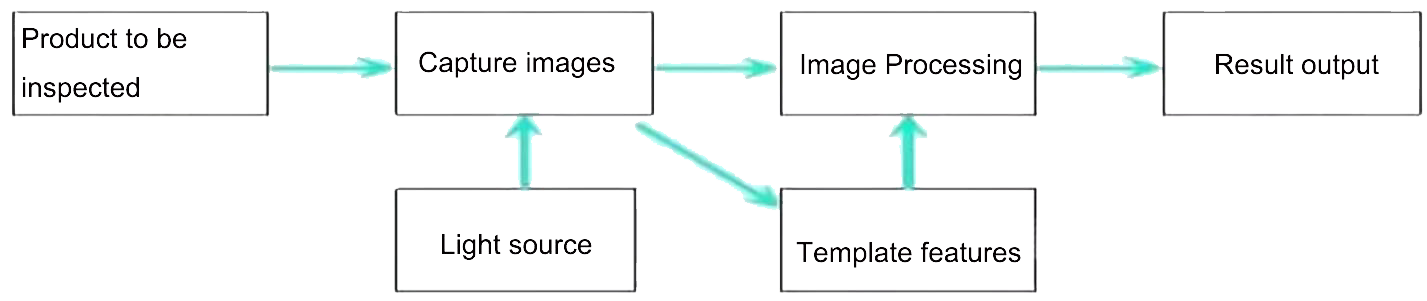

Inspection principle

Machine vision is a branch of artificial intelligence that is developing rapidly. At present, China is the third largest application market in the field of machine vision after the United States and Japan. KEYE TECH divides the functions of machine vision into detection, measurement, identification, and positioning, and introduces the application of machine vision.

Applications of vision system

1. Industrial testing applications

In industrial inspection, the outstanding advantages of machine vision, such as non-contact, fast speed, suitable precision, and strong on-site anti-interference ability, have been widely used, and huge economic and social benefits have been achieved.

It has been widely used in plate processing inspection, glass substrate surface inspection, PCB surface inspection, metal surface visual inspection, diode substrate inspection, printed circuit board defect inspection, automatic identification of weld defects, etc.

The use of machine vision in industrial inspection can improve the flexibility and automation of production. On the one hand, machine vision can be used in some dangerous working environments or occasions where artificial vision is difficult to meet the requirements; on the other hand, in the process of large-scale industrial production, machine vision inspection can greatly improve production efficiency and production intelligence.

2. Measurement application

It is mainly used to measure whether the dimensions of parts and various products are qualified. In addition to using industrial cameras for two-dimensional size measurement, currently, three-dimensional size measurement can be achieved using technologies such as structured light and 3D TOF. Provide high-precision monitoring of the basic feature size and assembly effect of the product.

The application of vision in measurement, on the one hand, reduces the need for manual measurement and reduces labor costs; on the other hand, visual measurement has the characteristics of high precision, and the possibility of false detection and misjudgment is extremely low.

3. Image recognition

Image recognition, simply put, is the use of machine vision to process, analyze and understand images, and to recognize a variety of objects and targets, which is very powerful. At present, it mainly recognizes various objects such as people and vehicles. In the industrial field, there are often identification requirements for identification with clear information, such as OCR, one-dimensional code, two-dimensional code, etc.

Identifying the identification of clear information helps to improve production efficiency and reduce production costs. Most commercial scenarios of image recognition still belong to the blue ocean, and the potential remains to be developed. At the same time, most of the picture data is mastered by large Internet companies, and the data resources of start-up companies are scarce.

4. Positioning application

In industrial applications, machine vision is used to locate parts or products. This positioning application will often assist robots or other actuators to achieve related actions. Generally speaking, positioning can assist the robot to realize actions such as painting, gluing, grasping, and welding.

Other hot fields involved in machine vision

5. Object sorting

In the application of machine vision, the application of object sorting is a link after identification and detection. The image is processed through the machine vision system, and the product sorting is realized by the use of the robotic arm.

In the past production line, the material was placed in the injection molding machine manually, and then the next step was carried out. Now, automated equipment is used for material distribution, in which machine vision system is used for product image capture, image analysis, and output results, and then robots are used to place corresponding materials in fixed positions, so as to realize intelligent, modern, and industrial production. automation.

6. Food packaging and pharmaceutical industry applications

Machine vision has a wide range of applications in the field of food packaging, and can be used to inspect the sorting and level measurement of bottles, the inspection of labels, lids, boxes, and the shape, size, tightness and integrity of bottles. Food packaging is an important guarantee for food quality, which can protect food from contamination during the circulation process, improve quality, and avoid safety accidents.

Machine vision plays a large role in many aspects such as drug packaging, quality inspection and control, helping the pharmaceutical industry to speed up the process of modernization and intelligence.

At present, machine vision detection is rich, stable and accurate in the detection links such as counting, coding, missing blister version, incomplete and fragmented medicines, installation instructions, and code identification, which meets the needs of packaging products in the pharmaceutical industry.