Anhui Keye Information & Technology Co., Ltd. |

|

Textile Socks Bulk Production Applications Of Machine Vision System

System features

| 1. AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2. Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3. Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4. High precision: detection accuracy can be high |

| 5. Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6. Easy to operate: It is easy to operate and easy to maintain |

| 7. Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

Inspection principle

This system is used for the detection of sock setting, and outputs the corresponding 0K/NG signal according to the detection result. The KVIS detection system developed by KEYE TECH. based on machine vision image processing technology is convenient for users to perform corresponding operations according to their needs. The software can automatically identify and complete the detection, and output corresponding control or warning signals.

This method refers to the linear transmission method. The socks need to run in one direction to the detection position, and the system will detect them. The qualified products output the 0K detection signal, and the unqualified products output the NG detection signal, so as to facilitate the subsequent equipment. to be processed.

Technical background

As a kind of equipment with a high degree of electrical integration, the sock machine produces products that occupy an important position in people's production and life. The existing sock machine is relatively complex in structure. In order to ensure the quality of the socks produced, the socks machine needs highly precise cooperation of various institutions in the production process of the required socks.

The existing sock machine is efficiently coordinated by electric and pneumatic methods, so as to ensure the efficiency of producing socks and the quality of socks, but the existing sock machine, in the production process, in case of failure, the production supervisor can only pass the agency The machine failure can only be found when unqualified socks are produced after the shutdown, and sometimes even a batch of unqualified socks can be found, and when a failure occurs, the sock machine needs to be suspended to find the specific failure of the sock machine. parts, which is not conducive to the production efficiency and the guarantee of the quality of socks in the production process.

Technical implementation elements

Our system provides a machine vision-based sock machine knitting detection system to overcome the problem of low production efficiency caused by the inability to accurately detect the production process of the sock machine in the prior art. . In order to achieve the above-mentioned purpose, the present invention provides a kind of sock machine knitting detection system based on machine vision, including:

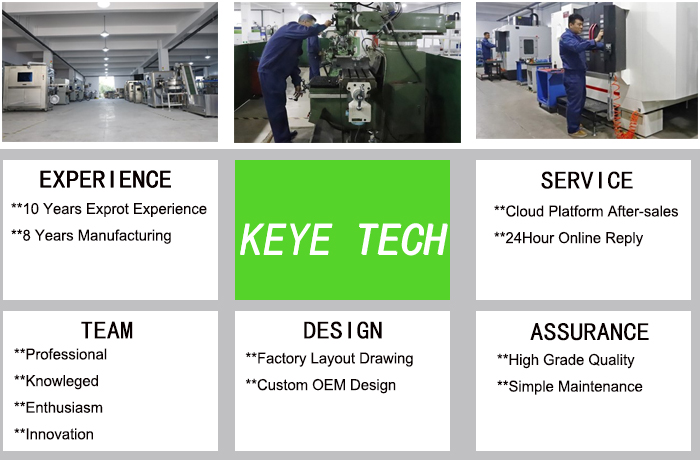

Our advantages