Anhui Keye Information & Technology Co., Ltd. |

|

Market background

Ketchup is a seasoning that is liked by many people, and there are many loyal fans around the world. Because tomato sauce is a thick-textured seasoning, it is often used with a sharp mouth when matching bottle caps. Ketchup is exposed to the air, and the contamination of bacteria and microorganisms can easily make it deteriorate and mold. The sharp mouth cover also facilitates the use of ketchup during the cooking process, and protects the unused ketchup from being affected. Tip caps are widely used in many aspects. Now many manufacturers have inspections for bottle caps. However, due to the large base of inspections, many manufacturers have to use the latest AI vision inspection technology.

Inspection principle

The AI inspection system integrates lid feeding and handing equipment, conveying mechanism, visual system hardware and inspection software, and defective product rejection device. The maximum inspection speed is about 30,000 pieces/hour, and the equipment can achieve 7*24 It runs 24 hours a day, which greatly improves production efficiency.

The inspection equipment is equipped with a total of 6 sets of high-pixel industrial cameras to comprehensively detect the appearance of defects of the product. After the system collects sample images, the image processing software is compared with standardized samples to determine good and defective products, and the defective products are automatically eliminated online. , The software will open the sample comparison standard, and the production personnel on the customer site can control the comparison accuracy and choose the accuracy standard most suitable for their own production conditions, thereby controlling the defect rate.

| System parameters | |||

Dimension | Reference the drawing | Voltage | 220V 20A 50HZ |

Power | 2.5-3.0kw | Air | 0.5~0.8MPa clean air without oil |

Temperature | -20℃ ~ 60℃ | Humidity | Less than 50% |

Inspection details

| Model | Number of camera | Inspection scope | Inspection content | Detection precision | Accuracy | Capacity |

KVIS -SC06 | 1 set | Top area | Black spot, stains (color difference ) | ≥0.2mm | 99% | Max 3000 pcs/hour |

| 4 sets | Outside area | Black spot, stains (color difference ) | ≥0.2mm | 99% | ||

Injection incomplete | ≥0.5mm | 99% | ||||

Flash | ≥0.5mm | 99% | ||||

| 1 set | Concave area | Black spot, stains (color difference ) | ≥0.2mm | 99% | ||

Transformation | ≥1.0mm | 99% | ||||

Flash | ≥0.5mm | 99% |

Advantages of visual inspection

1)High detection accuracy and fast detection efficiency:CCD visual inspection equipment uses machine control according to the system, with small error and high detection rate.

2)Wide detection range to detect cosmetic defects and dimensional measurements:The multi-station inspection method can accurately measure the outline, specifications, appearance defects, product aspect ratio and other performance parameters of the product to be inspected at one time.

3)Improve product quality and error rates:Vision inspection equipment is based on system control, which can distinguish good products from bad products through automatic inspection technology, and then automatically place them in different parts.

4)Save labor costs and enable high repetitive work:CCD visual inspection can work stably for a long time, it is difficult for human eyes to observe the same object for a long time, and machine vision can perform measurement, analysis and recognition tasks for a long time. And it can continue to work, with low requirements for the natural environment of the application, in addition to saving product costs, it also greatly improves productivity.

5)Improve company competitiveness and employee safety factor:Non-contact detection, which does not cause any damage to observers and observers, improves the reliability of the system. Machine vision technology guarantees the ultimate human-machine interaction technology, which ensures a better and safer workplace.

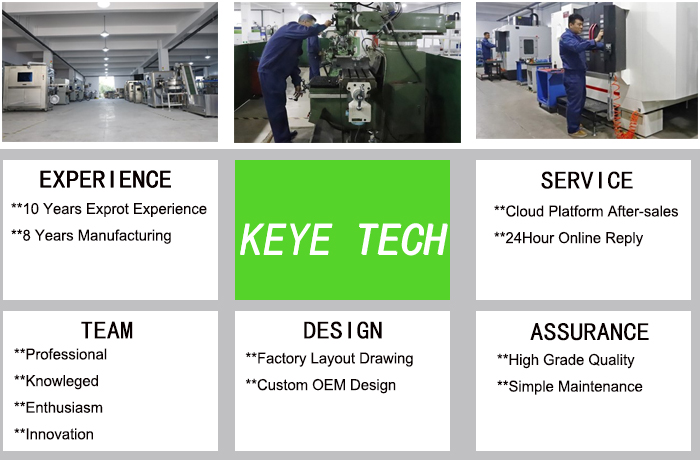

Our advantages