Anhui Keye Information & Technology Co., Ltd. |

|

Product background:

The battery cap is the core component of the lithium battery, which not only plays the role of stable conduction, but also is the sealing component of the battery, which plays an important role in protecting the internal structure of the battery and ensuring that the battery can be used safely. From raw materials to finished products, the battery cap needs to go through several processes of blanking, press-fitting, welding, and gluing, and the probability of defects is relatively high. Therefore, before the battery cap leaves the factory, quality inspection must be carried out. However, the automation level of battery cap quality inspection is still relatively low. The detection of defects such as welding, appearance, and assembly mainly relies on manual inspection. The inspection intensity is high and the false detection rate is high.

The technology applied by the more mature detection systems on the market is the picture comparison technology, which generates judgment results through simple grayscale and threshold calculations. However, there is no way to achieve the characteristics and classification requirements of wrong welding, partial welding, weak welding, etc. that require fuzzy judgment, or the false detection rate in the practice process is very high, and the machine replacement cannot be realized.

Inspection principle:

The visual inspection system for lithium battery cap defects developed by our company, this application realizes automatic loading and unloading operations during the inspection process of lithium battery caps, reduces the time required for the detection of the appearance defects of a single lithium battery cap, and greatly improves the overall performance of lithium battery caps. The detection efficiency of the battery can quickly complete the detection of the lithium battery cap, which improves the detection efficiency.

Inspection details&system equipment

The inspection machine adopts multiple sets of high-pixel industrial cameras and high-performance stroboscopic light sources to carry out omni-directional visual inspections for product appearance defects. The equipment can realize 7*24 hours of all-weather operation, and it can be online automatically. Eliminate substandard products.

| Name | Specifications | Remarks |

| Industrial Camera | Hikvision | China |

| Flat Lens | Azure | China |

| Stroboscopic Flash Source | Osram | Usa |

| Optical Sensor | Sick | Germany |

| Servo Driver | Delta B3 | Taiwan, China |

| Servo Motor | Deltab3 | Taiwan, China |

| Motion Controller | Delta Dvp-50Mc | Taiwan, China |

| High-Speed Solenoid Valve | Smc | Japan |

| High-Speed Cylinder | Smc | Japan |

| Industrial Power Supply | Mean Well | Taiwan, China |

| Circuit Trigger Board | Key-Pc-2.1 | China |

| Industrial Computer | Adlink B45 | Taiwan, China |

| Hd Touch Screen | Aoc | Taiwan, China |

Equipment installation conditions

Inspection space for equipment placement: To install Yingtaide visual inspection system separately on the side of the assembly line, it is necessary to ensure that there is enough space to install the equipment.

Ambient temperature: 0-50 degrees Celsius;

Air humidity: below 90% RH;

Electronic Interference: Provide equipment with a place where there is less electronic interference.

Power supply: AC 220V, 50Hz, power consumption <1KVA, air pressure 0.35~0.7MPa

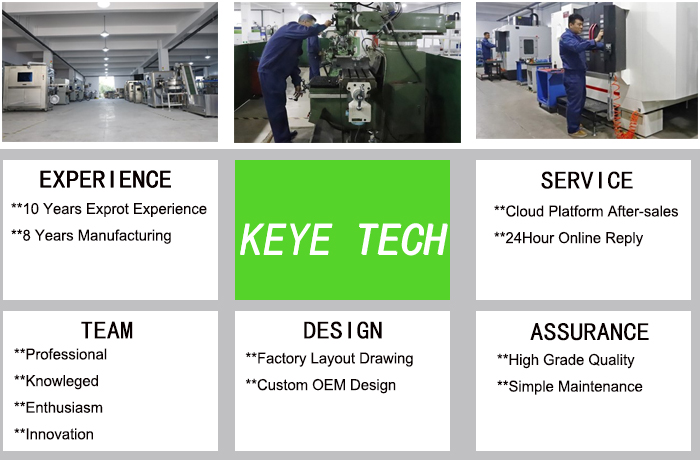

Our advantage