Anhui Keye Information & Technology Co., Ltd. |

|

The specific detection parameters are as follows:

| Model | Camera number | Detection range | Inspect | Accuracy | Precision | Speed |

| KVIS-SC03 | 1 set | Front of the plate | Black spots, stains, impurities | ≥1.0mm | 99.9% | 150 pcs/minute |

| Folds | width≥0.5mm length≥5.0mm | 99.9% | ||||

| perforation | Penetration≥0.5mm | 99.9% | ||||

| Non-penetration | 99.9% | |||||

| Rupture | width≥0.5mm length≥3.0mm | 99.9% | ||||

| Burrs | width≥0.5mm length≥1.0mm | 99.9% | ||||

| 1 set | Front of the plate (translucent) | Cracking | width≥0.5mm length≥3.0mm | 99.9% | ||

| Thinning | width≥0.5mm length≥3.0mm | 99.9% | ||||

| 5 set | Back of the plate | Black spots, stains, impurities | ≥1.0mm | 99.9% | ||

| Folds | width≥0.5mm length≥5.0mm | 99.9% | ||||

| perforation | Penetration≥0.5mm | 99.9% | ||||

| Non-penetration | 99.9% | |||||

| Rupture | width≥0.5mm length≥3.0mm | 99.9% | ||||

| Burrs | width≥0.5mm length≥1.0mm | 99.9% |

| System operating parameters | |||

| Dimensions | See the design drawings for details | Power and frequency | 220V 20A 50HZ |

| Total power | 5.0~6.0 kw | Air pressure | 0.5~0.8MPa Purify and oil-free |

| Working temperature | -20℃ ~ 60℃ | Working humidity | Below 50% relative humidity |

1. Detection products

Dinner plate products, paper-plastic material, white and primary

colors, are divided into various specifications, the disposable

dinner plates have greatly facilitated people's lives. Today, in

order to save costs, businesses have almost started to use

disposable plates in order to save costs, and bring some unique

patterns or printed brand logo. In a large number of market demand,

consumer experience directly affects the merchants strict

requirements on packaging quality. In order to increase the

production efficiency, the manufacturer changed the time-consuming

and labor-intensive manual detection, and instead chose to graft

the intelligent detection equipment to its own production line. So

far, Keye Tech has been engaged in the packaging detection industry

and has made a lot of dinner plate-related detection equipment. ,

There are good professional examples in the industry. Big data

intelligent algorithms can be used to update the detection data in

real time and discover possible problems in the production line in

time.

Now take the collected samples with diameters of 155mm, 175mm, and

235mm as examples (see actual samples for details) to introduce the

details of our detection equipment.

To achieve the compatibility detection of the above three products,

it needs to involve the front and back end automation mechanism,

the adjustment of the detection machine to the interface position

and the camera focal length, the switching application of the

detection software, etc., and the actual operation requires the

customer's on-site personnel to operate proficiently.

2. Detection principle

Through the docking of the feeding and separating mechanism, the

products are transferred to the specific detection station in a

stable and orderly manner in a front-up manner, and then transmits

the captured sample image to the image processing software through

the high-pixel industrial camera, compares with the standardized

sample and distinguishes the defective product and the good

product, and controls the corresponding pneumatic components to

reject defective products and finally collect qualified products.

The back-end conveying platform of the detection machine can stack

the tray mechanism for the receiving material.

The software sets the comparison standard for the samples,

operators can control the comparison precision and choose the

precision standard that best suits themselves, thereby controlling

the defect rate.

3. Detection details

Our design plan adopts 3 sets of high-pixel industrial cameras and

high-performance stroboscopic light sources to carry out a full

range of visual detection for the appearance defects of dinner

plate products. The detection speed is 150 pieces per minute. The

equipment can realize 7*24 hours of operation, and the unqualified

products can be automatically rejected online.

The whole set of detection equipment includes mechanical parts,

visual electronic hardware and detection system software. The

entrance and exit of the detection machine can be integrated with

the automation mechanism (see the design drawings for details), and

can be connected to upstream and downstream production according to

the specific production needs of customers on site equipment.

The overall equipment diagram is as follows:

1. Detection standards

Black spots, stains, hair, foreign bodies, impurities (different

colors), yellow spots, will be analyzed and processed according to

the black spot detection indicators. The difference in gray value

contrast must be greater than 40 to be effectively detected. If the

sample has transparent oil stains or light black spots, and the

gray value contrast difference is low (below 40), the detection

effect cannot be achieved.

In actual detecting, due to the critical fluctuation state of

certain detection item data affecting the judgment, it will cause a

certain probability of product misdetection. The parameter setting

of the system software can be adjusted to achieve the actual

effect.

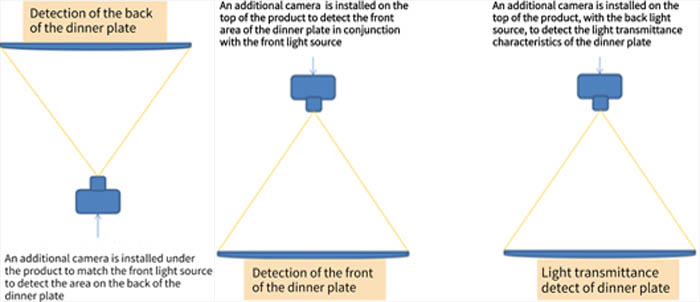

2. Instructions for camera use:

3. The detection equipment needs to be maintained and cleaned

regularly during use (such as conveyor belt cleaning, camera

cleaning, etc.), and the counting function can be realized after

the finished product is tested.

4. System composition

(1) Mechanical part:

The mechanical part is the core component of the system, which

carries all the transmission devices and electronic hardware

(industrial cameras, light sources, industrial computers, touch

screens, electrical boxes, etc.). The supporting glass turntable

mechanism in the equipment can open the imaging perspective of the

product and make Industrial cameras effectively collect images for

analysis and processing.

(2) Hardware part:

The hardware part includes cameras, lenses, light sources,

high-speed air valves, computers, touch screens and other

electrical devices.

5. Images collected by real machine (part of the diagram is for

reference only):

Frontal black spots and dirty