Anhui Keye Information & Technology Co., Ltd. |

|

| Item | Parameter |

| Voltage | AC220V/50HZ |

| Power | 400W |

| Air pressure | 2-3Kgf/cm² |

| Speed | 10000pcs/hr |

| Weight | 200KG |

| Dimension | 130cm×180cm×100cm |

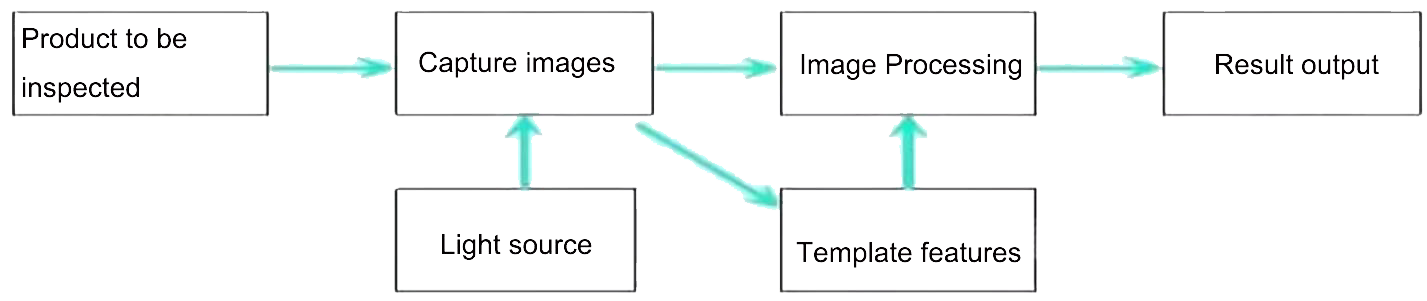

Inspection principle

The high-efficiency intelligent feather sorting machine uses AI deep learning algorithms to classify feathers (level 1, 2, 3, 4, 5,6), radius, folding, trimming and other categories. This software has advanced algorithms and multiple channels. High efficiency, instead of the traditional way of manually sorting feathers, it greatly saves time and labor costs, and improves the efficiency of the enterprise and the degree of industrial automation.

In the feather classification industry, there has been no more efficient machinery and equipment to classify feathers. The traditional way is rely on manual detection and classification, the inspection efficiency is low, and the accuracy cannot be guaranteed. In order to improve the efficiency of feather sorting and improve the detection accuracy, Keyi Technology has developed a high-efficiency intelligent feather sorting machine. The equipment mainly uses AI deep learning to classify feather types, with high detection efficiency and high accuracy, which can effectively replace manual detection and greatly improve the detection efficiency relative to manual detection. This equipment uses deep learning to greatly improve the accuracy of feather classification by training a large number of sample data, which is more efficient than traditional image recognition algorithms.

Traditional image processing algorithms need to design different image processing rules for different scenes. With the increase of scenes, the image processing rules will become more and more complex, and the recognition rate will be lower and lower. This software completely solves this problem of traditional algorithms.

This equipment uses deep machine learning algorithms to train different types of feather pictures without adding or modifying the code. After training, it has the function of identifying and classifying different types of feathers, which is more efficient in assisting the realization of the industry. Automation of detection.

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.