Anhui Keye Information & Technology Co., Ltd. |

|

Because of the extremely high nutritional value of cashews, their economic value has also increased. Then the production and processing requirements of nuts such as cashew nuts will be more stringent. The traditional use of manual inspection does meet the requirement of saving labor in the short term, but in the current fast-paced processing and production context, using manual inspection to control quality will lead to delays in products that cannot be sold at this level and cannot be sold to the market quickly. , affecting the competitiveness of commodities in the market.

Inpection principle

Compared with the machine vision inspection system and the traditional manual inspection, labor cannot continue to work for a long time, and it is impossible to guarantee the detection rate under continuous long-term work. The machine vision inspection system not only has almost 100% detection accuracy, but also under this premise. Do 7X24 hours of operation. So in the long run, the use of machine vision inspection achieves the three goals that every enterprise wants to achieve: labor saving, cost reduction, and quality control.

1. Loading

2. Lighting visual effects

3. Trigger two line scan cameras to shoot 360°

4. Detect surface defects: porous, cracked, non-cracked, half-cracked and fruit without shell.

5. Follow the fourth step to sort samples of different grades

KEYE currently independently develops visual inspection systems for industrial manufacturing enterprises, which have been successfully applied and widely praised in electronics, packaging, printing, chemical, food, plastic, textile and other industries.

Through the on-site application of machine vision inspection systems, production enterprises at all levels can significantly save labor costs while monitoring product production quality in real time and improving production efficiency.

Equipment configurations

| Model.No | KVS-GR | Inspect speed | 900-1200/min |

| Size | 800*600*600mm | Weight | 110kg |

| Voltage | 220V±10%,50Hz | Current | 500-1000W |

| Ambient temperature | 10~30℃ | Environment humidity | Relative temperature≤85% |

Key technology

1. Automatic binarization: Use deep neural network to segment the foreground and background of the image. Compared with the traditional binarization method, it can be applied to a variety of lighting conditions, and the edge segmentation of glutinous rice is smoother, fast and robust High advantages.

2. Adhesive glutinous rice segmentation algorithm: Connected glutinous rice cannot be segmented based on the method of connected domains. The deep neural network is used to segment the adhered glutinous rice at an instance level, which can reach a speed of 1000fps and can process the adhered glutinous rice in real time.

3. Nuomi attribute recognition algorithm: adopts a lightweight neural network and integrates a semi-supervised learning method. The model can be iteratively optimized only by marking a small amount of data. It has the advantages of high accuracy, fast speed, and convenient deployment.

Combining traditional machine vision methods and artificial intelligence algorithms to analyze glutinous rice. First, traditional visual methods are used to segment the glutinous rice grains in the video frame, and then artificial intelligence algorithms are used to identify the attributes of the segmented glutinous rice grains to determine whether there are insects. Moth, sprouting, mildew and other problems. At the same time, two high-resolution cameras were used to photograph the front and back of glutinous rice, and the properties of the two sides were analyzed. Through the registration algorithm, the front and back glutinous rice are registered one by one, and their respective attributes are combined to obtain the attributes of a complete glutinous rice grain.

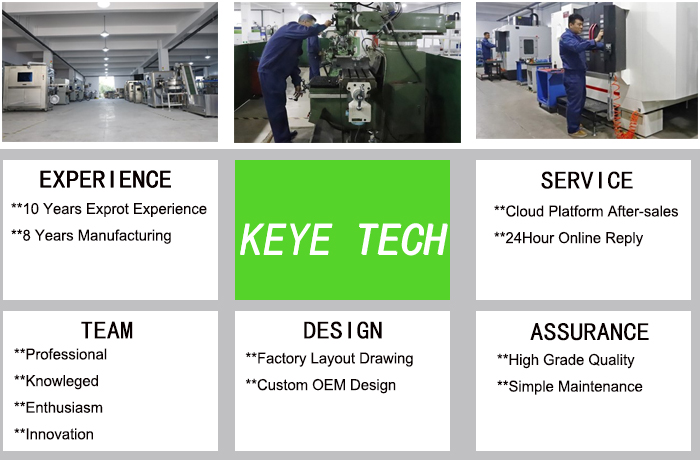

Our advantages