Anhui Keye Information & Technology Co., Ltd. |

|

Machine Vision Using On Dairy Label Shift And Packaging Visual Inspection System

| System operating parameters | |||

| Dimensions | See the design drawings for details | Power and frequency | 220V 20A 50HZ |

| Total power | 5kw ~ 6kw | Air pressure | 0.5~0.8MPa Purify and oil-free |

| Working temperature | -20℃ ~ 60℃ | Working humidity | Below 50% relative humidity |

Inspection standards

| Item | Camera | Position | Inspect | Accuracy | Speed |

| KVIS | 1 | Front area | foreign item,label issue(scratch,printing,skewing,etc.) | 99% | 4000pcs/h |

| 4 | Inner side | black spot,filling material,stain | |||

| 4 | Outside | ||||

| 1 | Bottom side |

Company profile

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

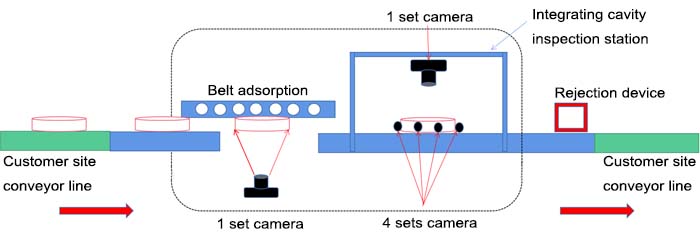

Inspection principle

Our company's design plan uses 10 sets of high-resolution industrial cameras and high-performance strobe light sources to conduct a full range of visual inspections for the appearance defects of plastic cup lid products.The detection speed is 4000 pieces per hour, and the equipment can operate 7*24 hours a day, and the unqualified products can be automatically eliminated online.

The whole set of testing equipment includes mechanical parts,

visual electronic hardware and testing system software. The

entrance and exit of the testing machine can be integrated with the

on-site conveyor line (specific docking

Please refer to the design drawings for details), and can connect

upstream and downstream production equipment (such as electrostatic

dust removal, disinfection and other production line equipment)

according to the specific production needs of customers.

Inspection results

Due to the complex structural features of the product, in the

actual detection application, there may be a very small range of

gaps in the junction area of the plane lens imaging and the

structural overlapping area.

Detection blind area, the image acquisition is not within the range

of this blind area, so it cannot be effectively detected.

in conclusion:

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.